Have you ever wondered how metal shapes are made? If so, you’re in for a treat. Metalworking has fascinated people for generations. One tool at the heart of this magic is the metal lathe. This machine is a true wonder of engineering.

Picture this: a solid piece of metal is spinning, and as it turns, it transforms. The metal lathe takes raw materials and helps create beautiful, precise shapes. One crucial part of this machine is the lathe belt. It connects the motor to the lathe, allowing it to spin at different speeds.

Did you know that the right lathe belt can make a big difference? It helps maintain speed and control, ensuring smooth operation. Imagine creating parts for cars, planes, or even art! Each turn of the lathe brings a new design to life.

Join us as we explore how the metal lathe and its belt work together to shape metal. Get ready to discover the secrets behind this fascinating process!

The Importance Of A Lathe Metal Shaping Metal Lathe Belt

Understanding Lathe Metal Shaping with a Metal Lathe Belt

When it comes to metal shaping, a lathe is crucial. But do you know how a metal lathe belt plays a role? This belt connects the motor to the lathe, helping spin the metal efficiently. A good belt ensures smooth cutting, which leads to better precision. Imagine transforming a rough metal block into a perfectly shaped part! Choosing the right lathe belt can make all the difference in your projects. Knowing this makes you a smarter metalworker!Components of a Metal Lathe

Description of key parts (headstock, tailstock, bed). The importance of a lathe belt in overall function.A metal lathe has several important parts that work together. The headstock is like the brain, controlling the tool’s speed. The tailstock holds the other end of the metal to keep it steady. Then there’s the bed, the long base that supports everything. Without these components, shaping metal would be harder than getting a cat to swim! Also, let’s not forget the lathe belt. It connects the motor to the spindle, helping everything run smoothly. Without it, you’re basically stuck in neutral, like a race car without gas!

| Component | Function |

|---|---|

| Headstock | Controls the tool’s speed and movement. |

| Tailstock | Stabilizes the metal piece being shaped. |

| Bed | Supports the entire lathe structure. |

| Lathe Belt | Connects motor to spindle for movement. |

Functions of the Lathe Belt

How the belt transfers power from the motor. Different types of lathe belts and their materials.The belt on a lathe acts like a superhero for machines. It carries power from the motor to the spinning parts. Think of it as the trusty sidekick that helps everything run smoothly! There are different types of lathe belts, made from various materials like rubber and leather. Some are strong and flexible, while others are easy to replace. Here’s a quick look:

| Type of Belt | Material | Notes |

|---|---|---|

| Rubber Belt | Rubber | Very common and durable. |

| Leather Belt | Leather | Old-school but still effective! |

| Polyurethane Belt | Polyurethane | Good for heavy-duty work. |

Choosing the right belt can make all the difference. So, pick wisely and watch your lathe transform into a shaping giant!

Choosing the Right Belt for Your Metal Lathe

Factors to consider when selecting a lathe belt. Comparing flat belts and round belts.Choosing the right belt for your metal lathe is key for smooth operation. Consider these factors:

- Size: Measure your lathe to find a perfect fit.

- Material: Choose strong materials for durability.

- Type: Decide between flat and round belts based on your needs.

Flat belts work well for high speed and long distances, while round belts are great for tight spaces and flexibility. Each has its strengths. Your choice impacts how well your lathe performs.

What should I consider for a lathe belt?

Size, material, and type are the most important factors. Selecting the right belt helps your lathe work better and last longer.

Installing and Maintaining Your Lathe Belt

Stepbystep guide to installing a lathe belt. Tips for regular maintenance and troubleshooting.First, grab your new lathe belt and locate the old one. Remove it with a twist, like unscrewing a jar lid! Then, place the new belt around the pulleys. Make sure it fits snugly; it shouldn’t be too tight or too loose, like your favorite pair of shoes. Afterward, check for any signs of wear and tear each month—this helps keep your lathe happy and running smooth. Remember, a happy lathe makes for a happy worker!

| Maintenance Tip | Description |

|---|---|

| Inspect Regularly | Check the belt for cracks or fraying to avoid sudden stops. |

| Keep Clean | Dust can cause friction. Keep things tidy! |

| Correct Tension | Too tight? Too loose? Both can ruin your day. |

Advantages of Proper Belt Usage in Metal Shaping

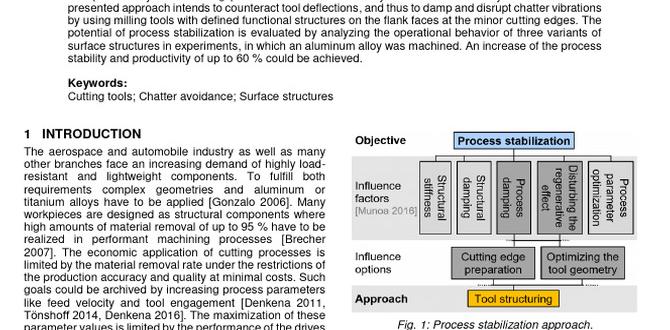

Impact on precision and efficiency of metal shaping. Common problems caused by belt issues.Using the correct belt in metal shaping improves both precision and efficiency. A good belt keeps the lathe running smoothly. This means fewer mistakes and less wasted material. Without a proper belt, problems can arise. Common issues include:

- Slack belts that cause vibration and misalignment.

- Worn-out belts leading to inconsistent cuts.

- Overheating due to friction, which can damage parts.

In short, using the right belt makes metal shaping better. It ensures accurate work and saves time and resources.

What are the benefits of using the right belt for metal shaping?

Using the right belt ensures smooth operation, reduces errors, and improves the overall quality of the metal shaping process. This helps to save time and materials, making projects more efficient.

Future Trends in Lathe Belt Technologies

Innovations in belt materials and designs. The evolving role of technology in metal shaping processes.New belt materials are making lathe machines even more exciting. Imagine belts that are lighter and tougher, like a superhero cape for your lathe! These innovations help machines run smoother and last longer. Technology is also changing the way we shape metal. There are cool gadgets now that can make precise cuts. It’s like giving the lathe a smart brain! As a result, both accuracy and efficiency in metal shaping are improving every day. Who knew making metal could be this fun?

| Innovation | Benefit |

|---|---|

| Lightweight belts | Reduced wear on machines |

| Smart technology | Increased precision |

Conclusion

In summary, a metal lathe is a powerful tool for shaping metal. By using a lathe, you can create precise and detailed parts. The metal lathe belt helps keep everything running smoothly. If you’re interested in metalworking, consider trying out a lathe. Explore resources online to learn more and start your own projects. Let’s get creative with metal!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Shaping Using A Metal Lathe And Its Belt:Sure! A metal lathe is a machine that helps us shape metal into different forms. The belt on the lathe moves the parts we want to work on. As it turns, you can use tools to cut and shape the metal. It’s like making a special piece of art but with metal. We must be careful and follow safety rules while using it!

Sure! Please provide the question you’d like me to answer.

What Are The Main Components Of A Metal Lathe, And How Does The Belt Drive System Contribute To Its Operation?A metal lathe has several important parts. The main ones are the bed, headstock, tailstock, and carriage. The headstock holds the motor and controls the movement. The belt drive system uses a belt to connect the motor to the lathe. This helps the lathe spin the metal piece so you can shape it easily.

How Do You Troubleshoot Common Issues With A Metal Lathe Belt, Such As Slippage Or Wear?To fix problems with a metal lathe belt, start by checking for slippage. If the belt slips, make sure it’s tight enough. You can also clean the belt and the pulleys to help it grip better. If the belt looks worn, replace it with a new one. Always wear safety gear and follow instructions when working.

What Materials Are Typically Used For Metal Lathe Belts, And How Do They Affect Performance?Metal lathe belts are usually made from rubber, leather, or polyurethane. Rubber belts are strong and flexible, helping machines run smoothly. Leather belts are tough and can last a long time but may need special care. Polyurethane belts are very durable and resist wear and tear. The material you choose affects how well the lathe will work.

How Can Adjusting The Tension Of The Lathe Belt Improve Machining Accuracy And Tool Life?Adjusting the tension of the lathe belt makes it tighter or looser. If it’s too loose, the machine may wobble and cut unevenly. This can make your work look messy. A proper tension helps the tool last longer because it doesn’t have to work harder than it should. By keeping the right tension, we can make cleaner cuts and save tools!

What Safety Precautions Should Be Taken When Working With A Metal Lathe, Particularly Concerning The Belt And Moving Parts?When using a metal lathe, always wear safety goggles to protect your eyes. Keep long hair tied back and wear fitted clothes so they don’t get caught. Check the belt and moving parts often to ensure they’re not damaged. Stand clear of the lathe while it’s in motion to avoid accidents. Always turn off the machine before making adjustments.

Sure! Just ask your question, and I’ll provide a simple answer.

Feel Free To Ask If You Need More Information!Sure! Just let me know what question you want me to answer, and I’ll be happy to help!