Have you ever wondered how metal is shaped into the tools we use every day? The secret often lies in a machine called a metal lathe. This powerful tool helps craftsmen create precise shapes from metal. One important part of this machine is the metal lathe carriage.

The carriage moves smoothly along the lathe, guiding the cutting tool. Without it, shaping metal would be much harder. Imagine trying to carve a statue from a huge block of stone without the right tools! The metal lathe carriage makes this process easier and more accurate.

Did you know that the first lathes date back thousands of years? They have evolved a lot since then. Today, modern lathes, with their advanced carriages, can make intricate designs quickly. Have you ever seen one in action? The way they work can be mesmerizing!

In this article, we will explore how the metal lathe carriage functions. We will uncover its importance in metal shaping. Ready to dive into the world of lathes? Buckle up as we uncover the magic of metalworking!

Lathe Metal Shaping: Understanding The Metal Lathe Carriage

Understanding the Metal Lathe Carriage

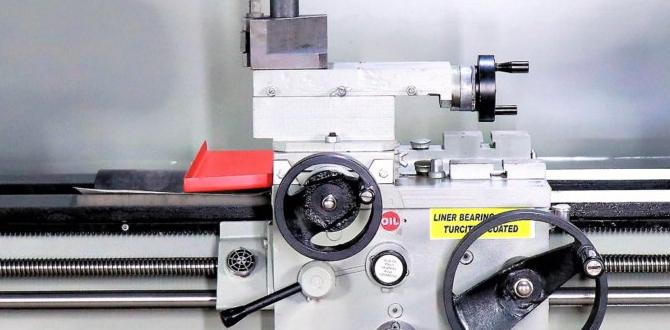

Have you ever wondered how metal is shaped? The metal lathe plays a crucial role in this process. The carriage is a vital part of the lathe. It holds and moves the cutting tool. This allows for smooth shaping and cutting of metal. Knowing how the carriage works helps you understand the entire shaping process. Did you know that the precision of the carriage can greatly affect the final product? It’s like having a skilled artist guiding your metal!Understanding the Basics of Metal Lathes

Definition and purpose of a metal lathe. Different types of metal lathes and their applications.A metal lathe is a machine that shapes metal. It spins a metal piece and cuts it into various shapes. The main purpose is to create precise parts for many products, from cars to toys. There are different types of metal lathes for various tasks:

- Engine lathe: Common at workshops for various projects.

- CNC lathe: Computer-controlled for high precision work.

- Turret lathe: Used for mass production with quick tool changes.

- Taper lathe: Makes cones and tapered parts easily.

Each type has unique uses, helping shape metal efficiently and accurately. This makes metal lathes essential tools in manufacturing.

What is a metal lathe used for?

A metal lathe is used to shape and cut metal into specific designs. It creates parts for cars, machines, and even home items.Metal Shaping Techniques Using a Lathe

Common metal shaping processes: turning, facing, and boring. Best practices for achieving precision and quality in metal shaping.Shaping metal can be like cooking, where every technique adds flavor to your final dish. Common processes include turning, where you spin the metal and carve it down. Facing is like trimming the edges to make them neat and smooth, while boring is all about making holes—think of it as drilling for treasure!

To achieve precision, use sharp tools and keep your lathe clean. Remember, a well-maintained lathe is like a sharpened pencil: it gets the job done better. For the best results, don’t rush; haste makes waste… and wobble! Here’s a quick table of these techniques:

| Technique | Description |

|---|---|

| Turning | Shaping metal by rotating it against a cutting tool. |

| Facing | Smoothing the ends of a workpiece. |

| Boring | Creating precise holes in metal. |

These methods ensure your metal shaping is top-notch, or should I say, “lathe-tastic”!

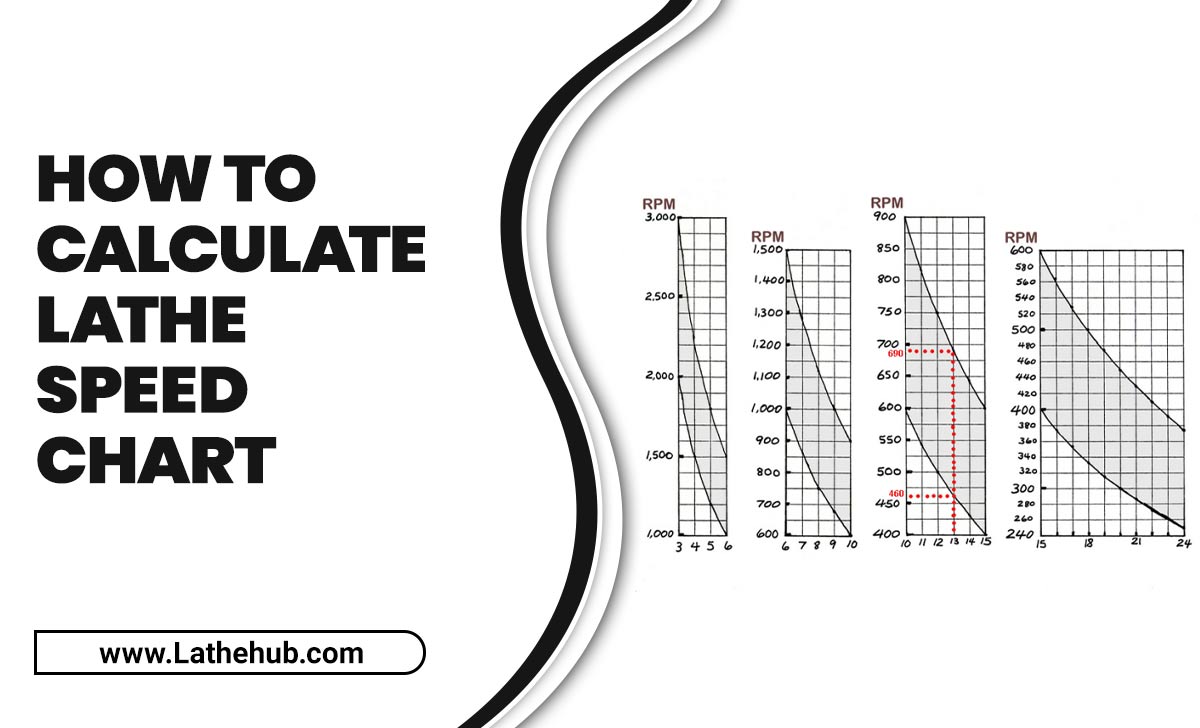

The Role of the Carriage in Metal Shaping

Detailed examination of carriage movement and adjustments. How to make precise cuts using the carriage controls.The carriage is like the heart of a metal lathe. It moves back and forth to make precise cuts. Adjusting the carriage is important to get the right shape. Imagine trying to cut a cake with a wobbly knife—yikes! To avoid that, you should know how to control it well. Proper movement helps create smooth, even surfaces. The more you practice, the more you’ll feel like a metal-shaping wizard! Here’s a simple chart to show how to adjust the carriage:

| Adjustment Type | Effect on Cuts |

|---|---|

| Horizontal Movement | Changes depth of cut |

| Vertical Movement | Alters angle of cut |

| Speed Adjustments | Smoother or rougher finishes |

With practice, you’ll make cuts that are as sharp as your wit!

Tools and Accessories for Lathe Metal Shaping

Essential cutting tools and tool holders. Recommended accessories to enhance lathe functionality.Want to shape metal like a pro? The right tools make a huge difference. Essential cutting tools include inserts and high-speed steel tools. Tool holders keep your tools secure. There are also great accessories to boost your lathe’s performance. They help with precision and ease of use. Check these out:

- Chuck: Holds the workpiece firmly.

- Tailstock: Adds support and stability.

- Quick-change tool post: Saves time during tool changes.

These tools and accessories make metal shaping easier and more efficient!

What are essential cutting tools for a lathe?

Essential cutting tools for a lathe include inserts and high-speed steel tools. These tools help create precise cuts in metal, making your project look great.

Safety Precautions When Operating a Metal Lathe

Personal protective equipment (PPE) and safety gear. Common hazards and how to mitigate risks while working with a lathe.Using a metal lathe can be fun, but safety is very important. Always wear personal protective equipment (PPE) like goggles, gloves, and earplugs. These items help protect you from flying chips and loud noises. Here are some common hazards and tips to keep safe:

- Wear tight clothing to avoid snagging.

- Keep your work area clean and free of clutter.

- Always check tools before you use them.

Remember, staying safe will help you enjoy your time while working.

What is Personal Protective Equipment (PPE) for a lathe?

Personal protective equipment (PPE) includes items like safety glasses, gloves, and aprons. These protect you from accidents and injuries while working on the lathe.

Common Hazards and How to Mitigate Risks

- Chips flying from the lathe can cause eye injuries. Always wear safety goggles.

- Loud noise can hurt your ears. Use earplugs for protection.

- Loose clothing can get caught in the lathe. Wear fitted clothes.

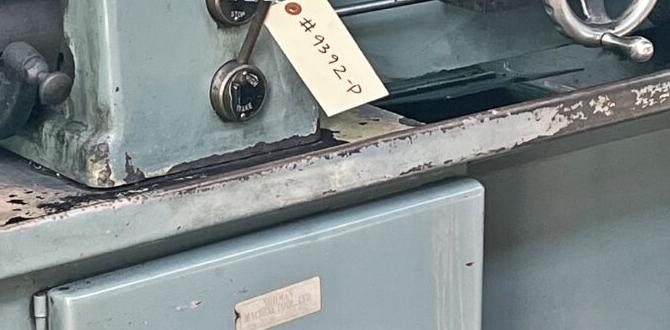

Maintenance Tips for Longevity of Your Metal Lathe

Routine maintenance checks and practices. How to troubleshoot common issues with the carriage and lathe components.Keeping your metal lathe in tip-top shape is easier than you think! Regular checks are like giving your lathe a health check-up. Look for loose screws and oil moving parts. Trust me, your lathe will thank you by working smoothly! If trouble arises with the carriage, check if it’s stuck. A little wiggle goes a long way! Here’s a quick table for some handy tips:

| Maintenance Task | Frequency |

|---|---|

| Check oil levels | Weekly |

| Clean surfaces | Before and after use |

| Tighten any loose bolts | Monthly |

Finally, if your lathe is making funny noises, it’s not telling jokes! It might need some love. Lubricate it, and it will hum happily again. Remember, a happy lathe is a productive lathe!

Advanced Techniques and Innovations in Metal Lathe Carriage Operations

CNC lathes and their impact on metal shaping industries. Exploring software integration for enhanced precision in lathe operations.Modern lathes have made a big difference in metal shaping. CNC lathes allow machines to run automatically. This speeds up the work and makes it more precise. With the right software, lathes can cut metal with amazing accuracy. These tools are essential for many industries today. They help create parts quickly and with less waste. Newer software plays a big role in this. It helps operators control every detail, making tasks easier and faster.

How are CNC lathes changing the industry?

These machines are changing the game in metal shaping. CNC lathes produce parts faster and more accurately than before. They help companies save time and reduce costs.

Key Benefits of CNC Lathes:

- Increased efficiency

- Improved accuracy

- Less material waste

- Automated processes

Real-World Applications of Metal Shaping with Lathes

Industries that benefit from lathe metal shaping. Case studies of successful lathe projects and outcomes.Many industries rely on metal shaping with lathes for creative solutions. For instance, the automotive industry uses lathes to create precise parts for vehicles. This ensures they run smoothly and safely. In the medical field, lathes help shape instruments, making surgeries safer. Let’s take a look at a few successful examples:

| Industry | Project | Outcome |

|---|---|---|

| Automotive | Engine Parts | Increased efficiency |

| Medical | Scalpel Manufacturing | Improved safety and precision |

| Aerospace | Aircraft Components | Enhanced performance |

These projects show how lathe metal shaping affects everyday life. They remind us that behind every part is a story of creativity, hard work, and maybe a little bit of oil-stained humor!

Conclusion

In summary, the lathe is a powerful tool for shaping metal. The metal lathe carriage helps move the cutting tool smoothly. You can create many shapes and designs using this machine. If you’re interested, consider experimenting with a lathe or reading more about its basics. Learning these skills can be fun and useful in many projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And The Metal Lathe Carriage:Sure! A lathe is a machine that helps shape metal and other materials. The metal lathe carriage is part of the lathe. It moves back and forth to help cut the metal. You can think of it like a sliding table that holds the tool. This helps us make nice shapes, like cylinders, from metal pieces.

Sure! Please provide the question you would like me to answer.

What Are The Primary Functions Of The Carriage In A Metal Lathe During The Shaping Process?The carriage on a metal lathe helps move the cutting tool. It can slide side to side and in and out. This lets you cut the metal into the right shape. The carriage holds the tool steady while you work. It makes shaping easier and more precise.

How Do Different Types Of Lathe Carriages (E.G., Flatbed Vs. Inclined Bed) Affect The Precision And Efficiency Of Metal Shaping?Different types of lathe carriages can change how well metal is shaped. A flatbed lathe has a flat surface, making it easy to move pieces and keep them steady. An inclined bed lathe tilts slightly, helping dirt and chips fall away. This makes both types work well, but the inclined bed can be faster and more precise. Overall, choosing the right carriage helps us get better shapes in less time.

What Are Some Common Problems That Can Occur With A Lathe’S Carriage, And How Can They Be Resolved?Common problems with a lathe’s carriage include sticking or jamming. This happens when dirt or old oil builds up. You can fix it by cleaning the carriage and adding fresh oil. Another problem is misalignment, which can make your work uneven. You can solve this by checking the parts and making sure they are straight.

How Do Advanced Features, Such As Power Feed And Threading Capabilities, Enhance The Performance Of A Metal Lathe Carriage?Advanced features like power feed and threading help a metal lathe carriage work better. Power feed lets the carriage move smoothly without you pushing it. This saves time and makes it easier to create shapes. Threading capabilities help us make screw threads accurately, which is important for fit and function. Together, these features improve our ability to make cool metal parts!

What Maintenance Practices Are Essential For Ensuring The Longevity And Accuracy Of A Metal Lathe Carriage?To keep a metal lathe carriage working well, you should clean it regularly. Dust and metal shavings can cause problems. You also need to oil the moving parts to keep them smooth. Check for any loose screws or parts and tighten them. Finally, make sure to protect it from rust by keeping it dry.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And The Metal Lathe Carriage:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps shape metal and other materials. The metal lathe carriage is part of the lathe. It moves back and forth to help cut the metal. You can think of it like a sliding table that holds the tool. This helps us make nice shapes, like cylinders, from metal pieces.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Functions Of The Carriage In A Metal Lathe During The Shaping Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The carriage on a metal lathe helps move the cutting tool. It can slide side to side and in and out. This lets you cut the metal into the right shape. The carriage holds the tool steady while you work. It makes shaping easier and more precise.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Lathe Carriages (E.G., Flatbed Vs. Inclined Bed) Affect The Precision And Efficiency Of Metal Shaping?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different types of lathe carriages can change how well metal is shaped. A flatbed lathe has a flat surface, making it easy to move pieces and keep them steady. An inclined bed lathe tilts slightly, helping dirt and chips fall away. This makes both types work well, but the inclined bed can be faster and more precise. Overall, choosing the right carriage helps us get better shapes in less time.”}},{“@type”: “Question”,”name”: “What Are Some Common Problems That Can Occur With A Lathe’S Carriage, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common problems with a lathe’s carriage include sticking or jamming. This happens when dirt or old oil builds up. You can fix it by cleaning the carriage and adding fresh oil. Another problem is misalignment, which can make your work uneven. You can solve this by checking the parts and making sure they are straight.”}},{“@type”: “Question”,”name”: “How Do Advanced Features, Such As Power Feed And Threading Capabilities, Enhance The Performance Of A Metal Lathe Carriage?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Advanced features like power feed and threading help a metal lathe carriage work better. Power feed lets the carriage move smoothly without you pushing it. This saves time and makes it easier to create shapes. Threading capabilities help us make screw threads accurately, which is important for fit and function. Together, these features improve our ability to make cool metal parts!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Essential For Ensuring The Longevity And Accuracy Of A Metal Lathe Carriage?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe carriage working well, you should clean it regularly. Dust and metal shavings can cause problems. You also need to oil the moving parts to keep them smooth. Check for any loose screws or parts and tighten them. Finally, make sure to protect it from rust by keeping it dry.”}}]}