Have you ever wondered how metal shapes get made? A lathe does this amazing work. It spins metal and helps turn it into fantastic shapes. But what if you could control this machine using a simple board? That’s where a metal lathe controller board comes in!

This board makes it easier for people to use the lathe. It turns complicated tasks into easy steps. Imagine you are creating a cool metal sculpture or a piece for your project. With a lathe and a controller board, you can bring your ideas to life quickly and safely.

Did you know that the lathe is one of the oldest tools for metal shaping? It has been around for centuries! Today, it is more advanced than ever. With modern technology, you can achieve amazing precision and creativity.

In this article, we will explore the fascinating world of lathe metal shaping and how a metal lathe controller board can unlock your potential. Are you excited to learn more? Let’s dive in and discover the possibilities!

Lathe Metal Shaping: Understanding The Metal Lathe Controller Board

Lathe Metal Shaping and Controller Boards

Creating metal shapes with a lathe can be fun and rewarding. A metal lathe controller board aids in making precise cuts and shapes. It helps users adjust speed, depth, and tools easily. Imagine crafting metal parts for projects or repairs! Fun fact: Many hobbyists love using lathes because they can turn raw metal into artistic creations. Understanding lathe technology opens up possibilities for anyone interested in DIY metalwork. Ready to shape your ideas into reality?

What is Metal Shaping?

Definition and significance in manufacturing. Various metal shaping techniques and their applications.

Metal shaping is the art of transforming metal into useful shapes. Think of it like playing with Play-Doh, but way cooler! It’s super important in manufacturing because it helps create everything from tiny screws to large airplane parts. Various techniques include machining, forging, and casting. Each technique has its special job. For instance, forging makes strong parts by shaping hot metal. Now, let’s take a quick look at some popular methods:

| Technique | Description | Application |

|---|---|---|

| Machining | Using tools to remove material. | Creating precise parts, like gears. |

| Forging | Shaping hot metal under pressure. | Making strong components like crankshafts. |

| Casting | Pouring molten metal into a mold. | Producing complex shapes, like engine blocks. |

Metal shaping keeps our world moving! Without it, we’d be stuck with only rocks and sticks. So, next time you use an item, think about all the cool metal shaping that brought it to life!

Understanding the Lathe Machine

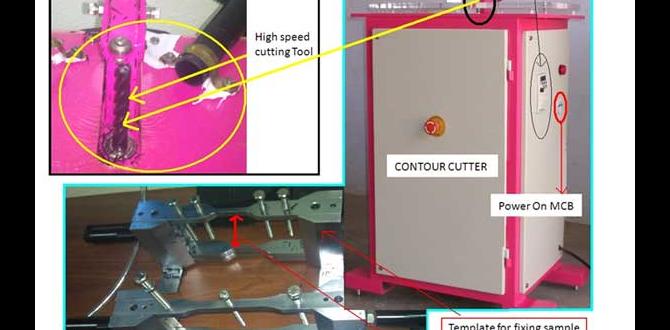

Components and functioning of a lathe machine. Types of lathes used in different industries.

A lathe machine is like the magic wand of metal shaping! Its main parts include a bed, headstock, tailstock, and carriage. These work together to hold and turn the material, shaping it just right. There are various types of lathes used in different jobs. For example, wood lathes are for crafting furniture, while metal lathes are superheroes in factories, shaping metal parts perfectly while making zero noise—well, almost!

| Type of Lathe | Used For |

|---|---|

| Wood Lathe | Making furniture and decorative items |

| Metal Lathe | Shaping metal parts and tools |

| CNC Lathe | High precision work with computer control |

Benefits of Using a Metal Lathe Controller Board

Enhanced precision and accuracy in metal shaping. Automation and ease of use for operators.

A metal lathe controller board offers great benefits for shaping metal. It improves precision in cuts, which makes every piece fit perfectly. Also, it makes tasks easier for workers, allowing them to focus on details instead of struggling with machine settings. With automation, the process becomes quicker and smoother. This means better products made in less time.

- Enhanced precision for perfect shapes

- Automation saves time and effort

- Easy-to-use for all skill levels

What is a metal lathe controller board?

A metal lathe controller board is a device that helps operate a lathe machine. It controls the movements needed to cut and shape metal accurately.

How to Choose the Right Controller Board for Your Lathe

Factors to consider when selecting a controller board. Tips for evaluating compatibility with existing equipment.

Selecting the right controller board for your lathe is important. Here are some key factors to consider:

- Compatibility: Check if the board works with your lathe’s model.

- Features: Look for features that suit your needs, like speed control.

- Size: Ensure it fits well in the existing setup.

- Reviews: Read reviews to learn from other users’ experiences.

Make sure to test the new board with your equipment before fully committing to it. Proper connections are key for smooth performance.

What should I consider when evaluating a controller board?

Look for strong compatibility with your lathe, suitable features, and read user reviews for insights. A good fit can lead to better shaping results!

Installation and Setup of a Metal Lathe Controller Board

Stepbystep guide for installation. Common troubleshooting tips during setup.

Installing a metal lathe controller board can seem tricky, but it’s easier than it sounds. Follow these steps for a smooth setup:

- Start with the right tools and materials.

- Carefully unpack the controller board.

- Connect power and wires as per the manual.

- Secure the board to the lathe.

- Turn on the lathe and check for errors.

If you run into problems, try these tips:

- Ensure all connections are tight.

- Check for any loose wires.

- Reset the system if it freezes.

With these steps, you can enjoy your metal lathe project!

What are common issues during setup?

Common issues include power failures and stepper motor errors. These problems can usually be fixed by checking connections and following the setup instructions closely.

Maintenance Tips for Metal Lathe and Controller Board

Routine maintenance practices to ensure longevity. Signs that indicate the need for repairs or replacements.

Keeping your metal lathe and controller board in tip-top shape is key to great results! Routine maintenance can include cleaning, checking belts, and lubricating parts. Think of it as a spa day for your machine! If you notice strange noises or if the power flickers, it might be time for repairs. Don’t wait for the machine to throw a tantrum; act before it becomes a bigger mess!

| Maintenance Tip | Signs of Trouble |

|---|---|

| Regularly clean your lathe | Abnormal sounds during operation |

| Lubricate moving parts | Inconsistent speeds |

| Check wiring connections | Overheating |

Remember, a happy lathe means smooth operation! So give it some love, and it will serve you well.

Case Studies: Successful Applications of Metal Lathe Controllers

Realworld examples showcasing benefits in production. Lessons learned from industry implementations.

Metal lathe controllers are making waves in many industries. For instance, a local automotive company improved production by 25% using one. They cut down setup time significantly. Another factory reduced mistakes, saving money and time. They trained workers effectively, making them more skilled. Here are some lessons learned:

- Change takes time, but it pays off.

- Training staff is very important.

- Regular updates on systems help.

By learning from these examples, others can follow their success.

What real-world benefits do metal lathe controllers offer?

These controllers boost efficiency, reduce errors, and lower costs. They help factories produce high-quality parts quickly and reliably.

Conclusion

In conclusion, a metal lathe is a powerful tool for shaping metal. The controller board helps you operate the lathe smoothly. By understanding how it works, you can create various projects with precision. We encourage you to explore more about lathe technologies and consider trying one yourself. It’s a fun way to learn and make cool things!

FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Metal Shaping And Metal Lathe Controller Board:

Sure! A lathe is a machine that helps shape metal into different forms. You put a metal piece on it, and it spins. As it spins, you use tools to cut and shape the metal. A metal lathe controller board helps you control how the lathe works. It tells the lathe when to start, stop, and how fast to go.

Sure! Please ask your question, and I’ll be happy to help you with a short answer.

What Are The Key Features To Look For When Selecting A Controller Board For A Metal Lathe?

When choosing a controller board for a metal lathe, you should look for a few important things. First, make sure it has enough power for your lathe. You also want it to be easy to use. It should be compatible with the tools and software you have. Finally, check if it has good support and documentation to help you learn.

How Does A Cnc Controller Board Improve The Precision And Efficiency Of Metal Shaping On A Lathe?

A CNC controller board helps us control a lathe better. It lets us move the cutting tool very precisely. This means we can make metal shapes exactly how we want them. It also speeds up the work, so we finish faster. With this board, we make fewer mistakes and save time!

What Types Of Software Are Compatible With Lathe Controller Boards For Programming Metal Shaping Operations?

You can use different types of software with lathe controller boards. Some common programs are Mach3, LinuxCNC, and Fusion 360. These help you create designs and control the lathe. You can also use simple programs that help you write instructions for the machine. They make it easier to shape metal the way you want.

Can You Explain The Differences Between Analog And Digital Controller Boards For Metal Lathes?

Sure! Analog controller boards use signals that change smoothly, like a dimmer switch for lights. They let you control the lathe in a simple way. Digital controller boards use numbers and computer code, making them more precise and flexible. You can easily change settings or use different programs with digital boards, while analog boards are more straightforward but less powerful.

What Safety Features Should Be Considered When Designing Or Purchasing A Controller Board For A Metal Lathe?

When designing or buying a controller board for a metal lathe, we should check for some safety features. First, make sure it has an emergency stop button. This lets you quickly turn off the machine if something goes wrong. You should also look for features that prevent it from running when the cover is open. Lastly, it’s important to have a good fuse to protect against electrical problems. These features help keep you safe while using the lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of A Lathe Metal Shaping And Metal Lathe Controller Board:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps shape metal into different forms. You put a metal piece on it, and it spins. As it spins, you use tools to cut and shape the metal. A metal lathe controller board helps you control how the lathe works. It tells the lathe when to start, stop, and how fast to go.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For When Selecting A Controller Board For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a controller board for a metal lathe, you should look for a few important things. First, make sure it has enough power for your lathe. You also want it to be easy to use. It should be compatible with the tools and software you have. Finally, check if it has good support and documentation to help you learn.”}},{“@type”: “Question”,”name”: “How Does A Cnc Controller Board Improve The Precision And Efficiency Of Metal Shaping On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A CNC controller board helps us control a lathe better. It lets us move the cutting tool very precisely. This means we can make metal shapes exactly how we want them. It also speeds up the work, so we finish faster. With this board, we make fewer mistakes and save time!”}},{“@type”: “Question”,”name”: “What Types Of Software Are Compatible With Lathe Controller Boards For Programming Metal Shaping Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use different types of software with lathe controller boards. Some common programs are Mach3, LinuxCNC, and Fusion 360. These help you create designs and control the lathe. You can also use simple programs that help you write instructions for the machine. They make it easier to shape metal the way you want.”}},{“@type”: “Question”,”name”: “Can You Explain The Differences Between Analog And Digital Controller Boards For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Analog controller boards use signals that change smoothly, like a dimmer switch for lights. They let you control the lathe in a simple way. Digital controller boards use numbers and computer code, making them more precise and flexible. You can easily change settings or use different programs with digital boards, while analog boards are more straightforward but less powerful.”}},{“@type”: “Question”,”name”: “What Safety Features Should Be Considered When Designing Or Purchasing A Controller Board For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing or buying a controller board for a metal lathe, we should check for some safety features. First, make sure it has an emergency stop button. This lets you quickly turn off the machine if something goes wrong. You should also look for features that prevent it from running when the cover is open. Lastly, it’s important to have a good fuse to protect against electrical problems. These features help keep you safe while using the lathe.”}}]}