Have you ever wondered how metal shapes get created? A metal lathe plays a key role in this process. It helps turn blocks of metal into precise shapes. But how does it do this?

At the heart of the metal lathe is something called the cross slide. This moving part allows the tool to cut into the metal smoothly. Imagine sculpting a piece of clay, only this time you’re working with metal!

Using a lathe is not just about making items. It’s about creating art in metal! Did you know that metal lathes date back to ancient times? They have transformed crafts since then!

In this article, we will explore how a lathe shapes metal. You’ll learn about how the cross slide works and why it’s important. Are you ready to dive into the world of metalworking?

Lathe Metal Shaping: Metal Lathe Cross Slide Explained

Understanding the Metal Lathe and Cross Slide

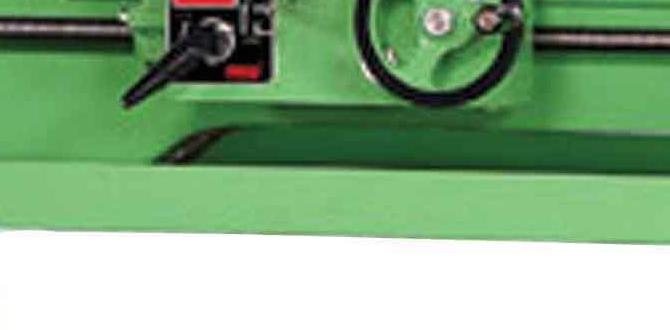

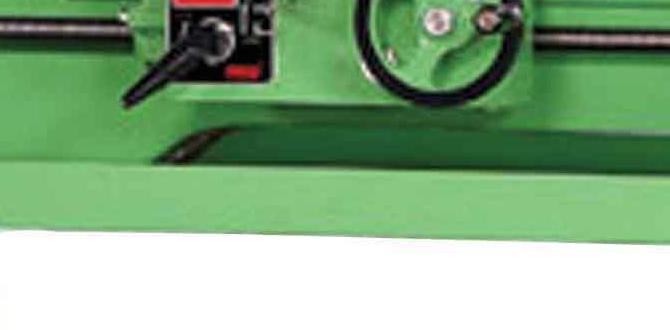

Have you ever watched a lathe in action? It’s fascinating! A metal lathe shapes metal using cutting tools. The cross slide is a key part of this tool. It allows for precise movements, helping to create accurate shapes. With the cross slide, you can move the tool horizontally and vertically. This feature is vital for fine details in metalworking. Knowing how this tool works can help anyone improve their crafting skills!

Understanding the Metal Lathe Cross Slide

Definition and function of the cross slide in metal lathes. Importance of the cross slide in precision machining.

The cross slide is a key part of a metal lathe. It moves the cutting tool side to side. This movement helps shape metal accurately. Without it, creating precise pieces would be like trying to cut a cake with a spoon—messy and chaotic! The importance of the cross slide in precision machining is huge. It ensures that parts fit together perfectly. In fact, using a cross slide properly can improve your work quality by more than 50%! Isn’t that a slice of fun?

| Function | Importance |

|---|---|

| Moves tool side to side | Ensures precise cuts |

| Adjusts tool position | Saves time and effort |

| Improves craftsmanship | Enhances overall quality |

Components of the Cross Slide

Key parts of the cross slide assembly. Materials used in cross slide construction.

The cross slide assembly has several key components that help it work smoothly. Here are the main parts:

- **Base**: This holds everything together.

- **Slider**: It moves side to side.

- **Lead Screw**: This helps the slider move.

- **Hand Wheel**: Users turn this to adjust positions.

These parts are usually made from strong materials like:

- **Cast Iron**: Great for stability.

- **Steel**: Ensures lasting strength.

- **Aluminum**: Light and easy to move.

Learning about these components helps in understanding how a metal lathe works.

What are the main parts of a cross slide?

Key parts include the base, slider, lead screw, and hand wheel.

What materials are used in cross slide construction?

Common materials are cast iron, steel, and aluminum.

Setting Up the Cross Slide for Operation

Steps for correctly positioning the cross slide. Tools required for cross slide setup.

To get the cross slide ready, start by securing it in the right spot on the lathe. Make sure it can move smoothly without any hiccups. You’ll need a few trusty tools for this setup, like a wrench and a level. Put the level on the cross slide to check if it’s straight, as no one likes a wobbly slide! Here’s a handy list to keep you on track:

| Tool | Purpose |

|---|---|

| Wrench | To tighten screws |

| Level | To check alignment |

| Caliper | For accurate measurements |

With everything set up, you’re ready to shape that metal like a pro! Remember, a happy cross slide makes for smooth operation. So, double-check your work and get ready for some lathe fun!

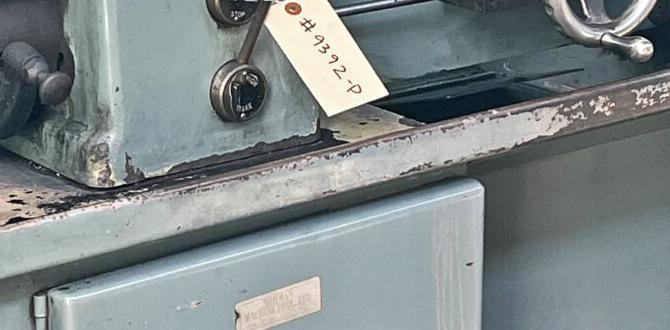

Common Issues with Cross Slides and Troubleshooting

Identifying and resolving common cross slide problems. Maintenance tips to prevent cross slide wear and tear.

Cross slides can face several common problems, but most are easy to fix. Look for sticking or wobbling, which can indicate dirt buildup or wear. Cleaning and regular oiling can keep them smooth. For long-lasting performance, check for tightness. If it feels loose, adjust it properly. Maintenance is key!

What are the common issues with cross slides?

Some common issues include sticking, wobbling, and uneven movement. These can be caused by dirt, lack of lubrication, or wear over time.

Tips for Maintenance:

- Regularly clean the slide and surrounding areas.

- Apply oil to moving parts every month.

- Check and adjust tightness frequently.

Safety Practices when Using the Cross Slide

Essential safety precautions for lathe operations. Common hazards and how to mitigate them.

Using the cross slide on a lathe can be safe if you follow these precautions. Always wear safety goggles to protect your eyes. Keep your hands clear of moving parts. Make sure the machine is off before adjusting the cross slide. Report any strange noises or vibrations to an adult. Common hazards include cuts or injury from the sharp tools. You can reduce these risks by being aware and cautious. Always follow these rules to stay safe while working.

What are some safety tips for using a lathe?

1. Wear protective gear. 2. Keep tools sharp. 3. Work in a clean area.

- Wear gloves when needed.

- Avoid loose clothing.

- Use clamps to secure workpieces.

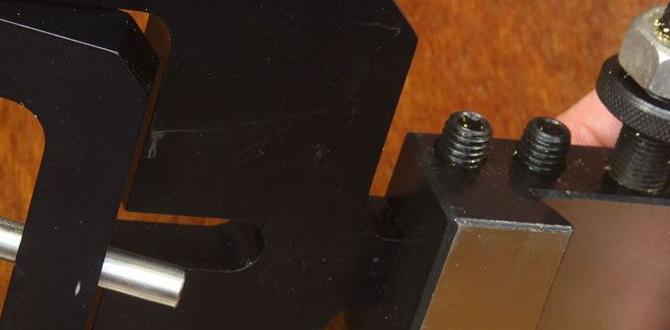

Enhancing Precision with Cross Slide Upgrades

Recommended upgrades for improved cross slide performance. Review of aftermarket cross slide options.

Upgrading your cross slide can make a big difference. It helps with accuracy and smooth movement. Here are some great upgrades to consider:

- Precision Ground Leadscrews

- Ball Bearing Supports

- Easy-to-Use Handwheels

- Upgrade Kits from Top Brands

Aftermarket options provide various features. They can enhance your tool’s performance. Look for brands known for quality. These upgrades can turn your lathe into a precision machine.

What are the benefits of cross slide upgrades?

Upgrades boost accuracy and control. They make tasks easier and more efficient. A smoother cross slide leads to better work results.

Real-World Applications of the Cross Slide

Case studies of successful projects utilizing the cross slide. Industries that benefit from metal lathe cross slide applications.

The cross slide is essential in many industries. Its precise movement allows for better metal shaping. Here are some examples of successful projects:

- In automotive manufacturing, cross slides help shape engine parts with high accuracy. This boosts engine performance.

- Aerospace companies use cross slides to craft lightweight components. This helps reduce the weight of aircraft.

- Medical device makers rely on cross slides for precision tooling. This ensures safety and effectiveness.

Many industries benefit from the metal lathe cross slide. It not only improves quality but also saves time and costs. Companies that use this tool often see increased production rates.

What projects benefit from using the cross slide?

Successful projects in automotive, aerospace, and medical sectors show how important the cross slide is.

Conclusion

In conclusion, using the lathe for metal shaping is a fantastic skill. The cross slide helps you get precise cuts and shapes. Remember to practice safely and regularly. If you’re curious about more techniques, we encourage you to explore tutorials or join a workshop. With time, you can master this valuable tool and create amazing projects!

FAQs

What Is The Primary Function Of The Cross Slide On A Metal Lathe, And How Does It Facilitate Precision Machining?

The cross slide on a metal lathe helps move the cutting tool side to side. This movement allows you to carve shapes accurately on the metal. By using the cross slide, you can make sure your cuts are straight and exactly where you want them. It makes machining easier and more precise, which gives you better results.

What Are The Key Differences Between The Cross Slide And Other Components Of A Metal Lathe, Such As The Carriage And Tailstock?

The cross slide is a part of a metal lathe that moves sideways. It helps you make cuts on the sides of the metal. The carriage moves the tool back and forth along the length of the metal. The tailstock holds tools and is fixed at the end of the lathe. Each part has a special job to help us shape metal properly.

How Can Operators Adjust The Cross Slide For Different Machining Operations, And What Tools Are Typically Required For These Adjustments?

You can adjust the cross slide by loosening the screws that hold it in place. Then, you move it to the right spot for your work. Finally, you tighten the screws again to keep it secure. To make these adjustments, you usually need a screwdriver and sometimes a wrench.

What Common Issues Can Arise With The Cross Slide On A Metal Lathe, And How Can They Be Resolved To Maintain Optimal Performance?

Common issues with the cross slide on a metal lathe include sticking and uneven movement. You can fix sticking by cleaning the slide and adding a little oil. If it moves unevenly, check and tighten the screws. Regularly checking these parts helps keep your lathe working well. Remember, good maintenance is key!

In What Ways Can The Design And Features Of The Cross Slide Impact The Accuracy And Finish Of The Machined Metal Parts?

The cross slide holds the cutting tools and moves them side to side. A good design helps you cut metal more exactly. If the slide is smooth, you get a better finish on the parts. Worn-out slides can make your cuts wobbly and rough. So, keeping the cross slide in great shape helps us make better metal pieces!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Primary Function Of The Cross Slide On A Metal Lathe, And How Does It Facilitate Precision Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The cross slide on a metal lathe helps move the cutting tool side to side. This movement allows you to carve shapes accurately on the metal. By using the cross slide, you can make sure your cuts are straight and exactly where you want them. It makes machining easier and more precise, which gives you better results.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between The Cross Slide And Other Components Of A Metal Lathe, Such As The Carriage And Tailstock? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The cross slide is a part of a metal lathe that moves sideways. It helps you make cuts on the sides of the metal. The carriage moves the tool back and forth along the length of the metal. The tailstock holds tools and is fixed at the end of the lathe. Each part has a special job to help us shape metal properly.”}},{“@type”: “Question”,”name”: “How Can Operators Adjust The Cross Slide For Different Machining Operations, And What Tools Are Typically Required For These Adjustments? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can adjust the cross slide by loosening the screws that hold it in place. Then, you move it to the right spot for your work. Finally, you tighten the screws again to keep it secure. To make these adjustments, you usually need a screwdriver and sometimes a wrench.”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise With The Cross Slide On A Metal Lathe, And How Can They Be Resolved To Maintain Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common issues with the cross slide on a metal lathe include sticking and uneven movement. You can fix sticking by cleaning the slide and adding a little oil. If it moves unevenly, check and tighten the screws. Regularly checking these parts helps keep your lathe working well. Remember, good maintenance is key!”}},{“@type”: “Question”,”name”: “In What Ways Can The Design And Features Of The Cross Slide Impact The Accuracy And Finish Of The Machined Metal Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The cross slide holds the cutting tools and moves them side to side. A good design helps you cut metal more exactly. If the slide is smooth, you get a better finish on the parts. Worn-out slides can make your cuts wobbly and rough. So, keeping the cross slide in great shape helps us make better metal pieces!”}}]}