Have you ever wondered how metal shapes into perfect forms? A metal lathe is a key tool in that process. It spins metal pieces at high speeds, allowing a craftsman to carve and shape them. But what makes this machine so special? One important part is the lead screw.

A lead screw helps control the movement of the metal. It guides the tool as it cuts through the metal. This feature makes the metal lathe a favorite for many makers and engineers. Imagine creating a beautiful, precise part just by turning a wheel!

Did you know that the lathe is one of the oldest tools used by humans? People have been shaping metal for thousands of years. From small jewelry to huge machine parts, the lathe has played a crucial role.

In this article, we will explore how a lathe works, focusing on the metal lathe lead screw. You will discover interesting facts and tips about metal shaping. Are you ready to dive into the world of lathes?

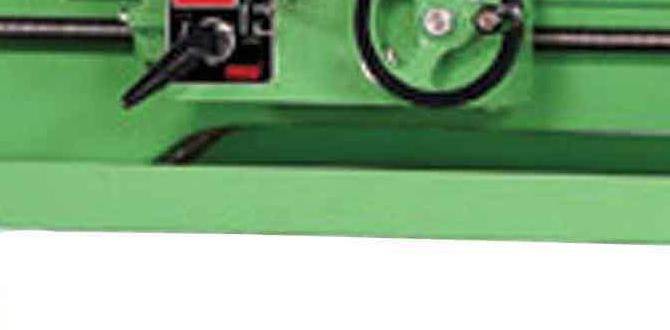

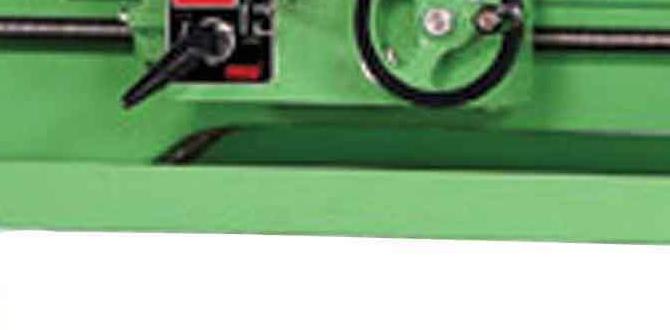

Lathe Metal Shaping: Understanding The Metal Lathe Lead Screw The Metal Lathe Is One Of The Cornerstones Of Modern Metalworking, Playing A Crucial Role In Shaping Materials To Precise Specifications. Among Its Various Components, The Lead Screw Is Essential For Controlling The Movement Of The Cutting Tool, Influencing Both The Quality Of The Finished Product And The Efficiency Of The Machining Process. In This Article, We Will Explore The Significance Of The Lead Screw In Lathe Metal Shaping, Its Functionality, Types, And Maintenance Tips For Optimal Performance. What Is A Metal Lathe? A Metal Lathe Is A Machine Tool Used For Shaping Metal And Other Materials. It Works By Rotating The Workpiece Against A Cutting Tool, Which Removes Material To Create Desired Shapes. Lathes Can Produce Cylindrical Objects, Threads, And More Complex Profiles, Making Them Invaluable In Manufacturing And Workshop Settings. The Role Of The Lead Screw The Lead Screw Is A Crucial Component In A Lathe That Facilitates Linear Movement Of The Carriage, Allowing For Precise Cuts And Adjustments. It Is Typically A Long Threaded Rod That Advances The Tool Post And The Carriage As It Rotates. The Lead Screw’S Movement Is Often Controlled By A Handwheel Or Automated Systems, Allowing Operators To Achieve Accurate Positioning Of The Cutting Tool. How The Lead Screw Works When The Lathe Is In Operation, The Rotation Of The Lead Screw Translates Into Linear Motion. As The Lead Screw Turns, The Threads Engage With A Nut Attached To The Carriage. This Connection Allows The Carriage To Slide Along The Length Of The Bed, Enabling The Cutting Tool To Move In Synchrony With The Rotation Of The Workpiece. Understanding This Relationship Is Key To Mastering Lathe Metal Shaping. Types Of Lead Screws There Are Various Types Of Lead Screws Used In Metal Lathes, Including: 1. **Acme Lead Screws:** These Are Commonly Utilized For Their Strength And Efficiency. They Have A Trapezoidal Thread Profile, Improving The Surface Contact And Reducing Backlash. 2. **Square Lead Screws:** These Provide Even Greater Stability And Are Typically Used In Precision Applications Where Accuracy Is Critical. 3. **Ball Lead Screws:** Often Used In High-Performance Lathes, Ball Screws Offer Minimal Friction And Wear, Resulting In Smoother Motion And Higher Accuracy. Maintenance Tips For The Lead Screw Proper Maintenance Of The Lead Screw Is Essential For Maintaining The Lathe’S Performance And Longevity. Here Are Some Tips: – **Regular Lubrication:** Ensure That The Lead Screw Is Well-Lubricated To Prevent Wear And Tear. Use Appropriate Oils That Are Compatible With Metal. – **Check For Backlash:** Regularly Assess The Lead Screw For Any Backlash, Which Can Impact Precision. Adjustments May Be Necessary To Tighten The Connection. – **Cleanliness:** Keep The Lead Screw Free From Debris And Contaminants That Could Interfere With Its Smooth Operation. – **Inspect For Damage:** Routinely Check For Any Signs Of Damage Or Wear, And Address Issues Promptly To Avoid Further Complications. Conclusion The Lead Screw Is An Integral Part Of The Metal Lathe, Playing A Vital Role In The Process Of Lathe Metal Shaping. By Understanding Its Function And Maintaining It Properly, Machinists Can Ensure Optimal Performance And Accuracy In Their Projects. Investing Time In Learning About The Lead Screw Will Ultimately Enhance Your Machining Skills And Help You Achieve Superior Results In Metalworking.

Understanding the Metal Lathe and its Lead Screw

A metal lathe is a powerful tool for shaping metal. It spins the metal to create precise shapes. The lead screw is crucial for moving the cutting tool accurately. Imagine trying to cut a straight line freehand versus using a ruler! With the lead screw, you get that perfect line every time. Fun fact: the first lathes date back to ancient Egypt. Learning how these machines work can inspire your creativity and projects. Want to shape metal like a pro? Dive in!

What is a Lathe and its Applications?

Definition and purpose of a metal lathe. Common uses in various industries.

A metal lathe is a special machine for shaping and cutting metal. It spins the metal while tools cut it into different shapes. The main purpose is to create parts that fit together perfectly in machines or tools. A metal lathe is useful in many industries, such as:

- Automotive – Making car parts.

- Aerospace – Creating precise components for airplanes.

- Manufacturing – Producing tools and equipment.

With a lathe, workers can create complex shapes easily and quickly. This machine helps to make everyday items that we see around us.

What are common uses of a metal lathe?

Common uses include making precise parts, tools, and custom designs across various industries.

The Role of the Lead Screw in a Metal Lathe

Explanation of the lead screw’s function. Importance of accuracy and precision in metal shaping.

The lead screw is like the brain of a metal lathe, guiding it precisely. It helps move the cutting tool smoothly along the metal. This smooth movement is key, as even a tiny mistake can turn a nice piece of metal into a funky shape. Without accuracy, your project might end up looking like a wobbly pancake instead of a sharp gear. So, precision matters! Think of it as the difference between a fine watch and a broken clock. A good lead screw leads to great results!

| Function | Importance |

|---|---|

| Guides tool movement | Ensures accuracy |

| Controls cutting depth | Improves finish quality |

| Enables repeatability | Reduces waste |

How to Choose the Right Lead Screw for Your Lathe

Factors to consider (material, length, thread type). Recommendations based on usage type.

Choosing the right lead screw for your lathe is important. Several factors help you decide:

- Material: Look for strong materials like steel for durability.

- Length: Measure the distance you need to cover. A longer lead screw allows for larger projects.

- Thread Type: Different projects need different thread shapes. Choose what suits your work best.

For hobbyists, a basic lead screw works. For professionals, invest in a high-quality one. This will help improve your results.

What factors should I consider when choosing a lead screw?

Consider material, length, and thread type to find the best fit for your lathe’s needs. These factors affect performance and durability.

Maintenance Tips for Lathe Lead Screws

Routine maintenance practices to ensure longevity. Common issues and how to troubleshoot them.

Keeping your lathe lead screw in top shape is easy with routine care. Regularly clean it to remove dust and chips. Check the lubrication every week. Proper lubrication helps it move smoothly. Watch for unusual noises or stiffness. These can be signs of wear. If you notice them, inspect the screw for damage. Replace it if needed to avoid more problems.

Common Issues and Solutions

- Noise: Check for dirt build-up or lack of lubrication.

- Stiff Movement: Clear debris and apply oil.

- Inconsistent Performance: Inspect the lead screw for damage.

Upgrading Your Metal Lathe Lead Screw

Signs that indicate the need for an upgrade. How to select and install an upgraded lead screw.

Your metal lathe may need a lead screw upgrade if you notice uneven cuts, excessive noise, or difficulty in movement. These signs mean your lathe isn’t working well. Upgrading can improve performance and precision.

When picking a new lead screw, follow these simple steps:

- Check the size and thread type of your current screw.

- Choose a high-quality, durable material.

- Read reviews and compare options before buying.

To install the upgraded lead screw, remove the old one first. Make sure to follow the instructions carefully. A new lead screw can transform your lathe into a more effective tool!

How do you know when to upgrade?

If your metal lathe makes irritating sounds, it may be time for a replacement. Ensure your lathe runs smoothly for better results in your projects.

What to consider for a lead screw upgrade?

Key factors include size, thread type, and material quality. A reliable lead screw enhances cutting accuracy and efficiency.

Innovations in Lathe Lead Screw Technology

Recent advancements in lead screw design. Benefits of modern lead screw technology for metal shaping.

Lead screw designs have jumped light-years ahead with new innovations! Recent advancements have made these screws smoother and more precise. Now, they can help shape metal like a knife through butter. With modern technology, machines have better speed and accuracy, making work easier. Just imagine making perfect cuts every time—no more guesswork! It’s like having magic powers in your workshop!

| Feature | Old Lead Screws | Modern Lead Screws |

|---|---|---|

| Smoothness | Rough | Sleek |

| Precision | Okay | Spot-On! |

| Speed | Slow | Fast as Lightning! |

These improvements allow for better results and save time. It’s like upgrading from a bike to a rocket ship! Who wouldn’t want that in their toolbox?

Case Studies: Successful Applications of Lead Screws in Metal Shaping

Realworld examples of effective lead screw usage. Lessons learned and best practices from the field.

Lead screws play a key role in shaping metal. Many businesses have used them successfully. For instance, one company used lead screws to increase their production speed. This move doubled their output and saved time. Another business reported fewer errors while using lead screws, leading to better product quality. Here are tips from these successes:

- Keep lead screws clean and well-lubricated.

- Choose the right size for your machine.

- Regularly check for wear and tear.

By following these practices, companies can improve their metal shaping operations.

What are successful examples of lead screw usage?

Successful examples include a factory that boosted output by 50% and a workshop that reduced errors by 30%. These examples highlight the importance of lead screws in metal shaping.

Conclusion

In conclusion, understanding the lathe and its lead screw is vital for shaping metal. This tool helps you create precise, smooth shapes in your projects. As you explore metalworking, remember the importance of the lead screw in guiding movements. Keep practicing and consider reading more about different lathe techniques. You’ll gain skill and confidence in no time!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping, Specifically Focusing On The Lead Screw:

A lead screw is an important part of a lathe. It helps move the cutting tool in a straight line. When you turn the lead screw, it makes metal shapes perfectly. You can make things like bolts or screws using this tool. It helps you create precise and nice shapes!

Sure! Just give me the question you’d like me to answer.

What Is The Primary Function Of The Lead Screw In A Metal Lathe, And How Does It Influence The Accuracy Of The Machining Process?

The lead screw in a metal lathe helps move the cutting tool smoothly. It turns to make sure the tool goes in a straight line. This movement is very important for making pieces that fit together perfectly. If the lead screw works well, you get more accurate results in your work. That means your metal pieces will be the right size and shape.

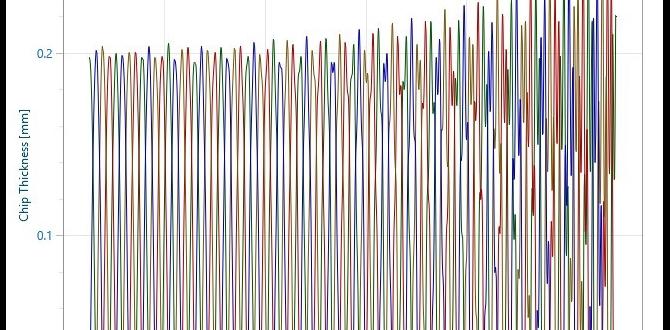

How Do Variations In Lead Screw Pitch Affect The Longitudinal Movement And Feed Rate During Metal Shaping Operations On A Lathe?

The lead screw pitch is how far the screw moves with one turn. If the pitch is bigger, the tool moves further with each turn. This means you can shape metal faster. If the pitch is smaller, it takes more turns to move the tool, making it slower. So, changing the pitch changes how quickly you can work!

What Are Some Common Maintenance Practices For Ensuring The Lead Screw Remains In Optimal Working Condition In A Metal Lathe?

To keep the lead screw on a metal lathe working well, we need to do a few simple things. First, check it regularly for dirt and dust. You can clean it gently with a cloth. Second, add a bit of oil to keep it smooth and prevent rust. Finally, make sure it’s tight and not wobbly. This way, it will work better for your projects!

How Does The Design Of The Lead Screw Differ Between Manual And Cnc (Computer Numerical Control) Lathes, And What Implications Does This Have For Metal Shaping?

In manual lathes, the lead screw helps us turn things by hand. You control the movement yourself, so it’s slower. In CNC lathes, the lead screw moves automatically using a computer. This makes shaping metal much faster and more precise. With CNC, we can create very detailed designs quickly.

What Are The Potential Causes Of Backlash In A Lead Screw System, And How Can It Be Minimized To Improve Precision In Lathe Operations?

Backlash happens when there’s extra space in the lead screw system, making it less accurate. It can be caused by worn parts, loose connections, or dirt. To reduce backlash, you can tighten the screws, clean the parts, or replace worn pieces. This helps the lathe work better and makes your cuts more precise.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping, Specifically Focusing On The Lead Screw:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lead screw is an important part of a lathe. It helps move the cutting tool in a straight line. When you turn the lead screw, it makes metal shapes perfectly. You can make things like bolts or screws using this tool. It helps you create precise and nice shapes!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of The Lead Screw In A Metal Lathe, And How Does It Influence The Accuracy Of The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lead screw in a metal lathe helps move the cutting tool smoothly. It turns to make sure the tool goes in a straight line. This movement is very important for making pieces that fit together perfectly. If the lead screw works well, you get more accurate results in your work. That means your metal pieces will be the right size and shape.”}},{“@type”: “Question”,”name”: “How Do Variations In Lead Screw Pitch Affect The Longitudinal Movement And Feed Rate During Metal Shaping Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The lead screw pitch is how far the screw moves with one turn. If the pitch is bigger, the tool moves further with each turn. This means you can shape metal faster. If the pitch is smaller, it takes more turns to move the tool, making it slower. So, changing the pitch changes how quickly you can work!”}},{“@type”: “Question”,”name”: “What Are Some Common Maintenance Practices For Ensuring The Lead Screw Remains In Optimal Working Condition In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the lead screw on a metal lathe working well, we need to do a few simple things. First, check it regularly for dirt and dust. You can clean it gently with a cloth. Second, add a bit of oil to keep it smooth and prevent rust. Finally, make sure it’s tight and not wobbly. This way, it will work better for your projects!”}},{“@type”: “Question”,”name”: “How Does The Design Of The Lead Screw Differ Between Manual And Cnc (Computer Numerical Control) Lathes, And What Implications Does This Have For Metal Shaping?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In manual lathes, the lead screw helps us turn things by hand. You control the movement yourself, so it’s slower. In CNC lathes, the lead screw moves automatically using a computer. This makes shaping metal much faster and more precise. With CNC, we can create very detailed designs quickly.”}},{“@type”: “Question”,”name”: “What Are The Potential Causes Of Backlash In A Lead Screw System, And How Can It Be Minimized To Improve Precision In Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Backlash happens when there’s extra space in the lead screw system, making it less accurate. It can be caused by worn parts, loose connections, or dirt. To reduce backlash, you can tighten the screws, clean the parts, or replace worn pieces. This helps the lathe work better and makes your cuts more precise.”}}]}