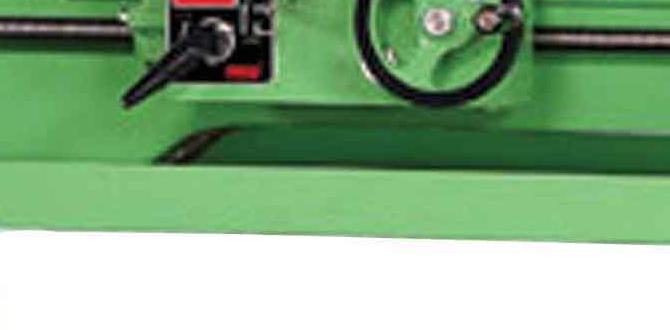

Have you ever wondered how metal parts are shaped so precisely? The answer lies in the magic of a lathe. A lathe is a powerful machine used in metal shaping. It spins metal pieces against tools to carve them into the exact shape needed.

Imagine a block of metal transforming into a perfect cylinder before your eyes. It’s like watching a sculptor at work! Metal lathe parts play a vital role in this process. Each part is carefully designed to ensure accurate and smooth shaping. This means we can create everything from tiny screws to large engine components.

Did you know that the lathe has been around for thousands of years? Early versions date back to ancient Egypt. Today, we have modern lathes that are faster and more precise. These machines have opened countless doors for inventors and builders.

So, what makes a metal lathe so special? How does it work? In this article, we will explore the fascinating world of lathes and their parts. Get ready to dive into the art of metal shaping!

Lathe Metal Shaping: Essential Metal Lathe Parts Explained

Lathe Metal Shaping: Understanding Metal Lathe Parts

Metal lathes are powerful machines that shape metal into precise forms. They spin the metal while cutting tools create different shapes. Key parts include the bed, tailstock, and carriage. Each part helps the lathe function smoothly. Did you know that ancient craftsmen used simpler versions of lathes thousands of years ago? Learning about these tools opens up a world of creativity and craftsmanship for anyone interested in metal shaping. Wouldn’t you want to explore this fascinating process?

What is a Lathe?

Definition and function of a lathe. Brief history and evolution of lathe technology.

A lathe is a special tool used for shaping metal and wood. It spins materials around a strong support. This helps create parts that are round and smooth. For example, it can make things like metal shafts or wooden tables. The lathe has a history that goes back thousands of years, evolving from hand tools to modern machines.

Today, lathes are an important part of manufacturing. They help create precise parts for machines and vehicles. Their development has made them faster and more accurate.

How Does a Lathe Work?

A lathe works by holding the material securely and rotating it. This allows cutting tools to shape the material. It’s like carving a piece of clay but with metal or wood!

Interesting Lathe Facts

- The oldest lathes date back to ancient Egypt!

- Modern lathes can be computer-controlled for precision.

- Lathes are used in many industries, from furniture making to aerospace.

What is a lathe typically used for?

A lathe is mainly used for shaping and cutting materials into specific forms. This makes it essential in various crafts and industries.

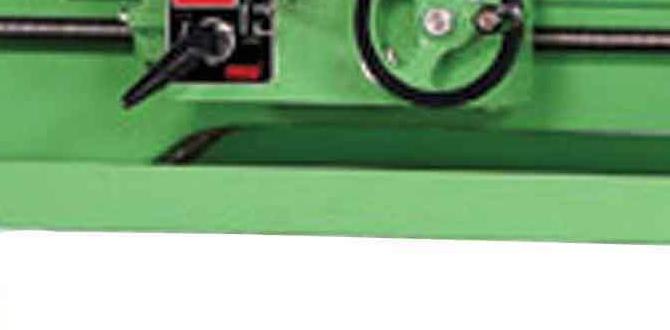

Key Components of a Metal Lathe

Explanation of essential metal lathe parts (e.g., bed, headstock, tailstock). Functionality of each component in the shaping process.

Every metal lathe has key parts that help it work like a champ! First, there’s the bed. It’s like the lathe’s backbone, keeping everything aligned and stable. Next up is the headstock. This is where the magic happens. It holds the spindle, which spins the metal round and round. Finally, we have the tailstock. It supports the other end of the metal piece, making sure it doesn’t wobble like jelly on a plate. Let’s take a quick look at these parts in the table below:

| Component | Function |

|---|---|

| Bed | Supports and stabilizes the lathe |

| Headstock | Holds the spindle for spinning the metal |

| Tailstock | Supports the other end of the workpiece |

These parts work together to shape metal smoothly. It’s like a team sport, but without the sweaty uniforms!

Metal Shaping Techniques Using a Lathe

Common techniques for shaping metal (e.g., turning, facing, drilling). Stepbystep breakdown of specific shaping processes.

Shaping metal on a lathe is like playing with playdough but with serious tools! You can use techniques such as turning, facing, and drilling to create amazing shapes. Turning means spinning the metal to carve it into a desired form, while facing flattens the end of a piece. Drilling? That’s for making holes. Let’s break them down step-by-step.

| Technique | Description |

|---|---|

| Turning | Spins the metal to shape it. |

| Facing | Flattens the ends for a clean look. |

| Drilling | Makes holes to fit parts together. |

Each technique has its charm and tricks. You might even find that making metal spin is more fun than a merry-go-round! Happy shaping!

Materials Used in Lathe Metal Shaping

Types of metals suitable for lathe work (e.g., steel, aluminum, brass). Considerations for selecting the right material for a project.

Choosing the right metal for lathe work is key to making awesome creations. Common metals include steel, aluminum, and brass. Steel is strong and tough, while aluminum is light and easy to shape. Brass shines and has a nice finish. Think about what you need your project to do. Is it about strength or weight? Remember that each metal has its quirks. Oh, and if your project involves a lot of laughter, I recommend aluminum— it’s pretty light-hearted!

| Metal Type | Properties |

|---|---|

| Steel | Strong, durable |

| Aluminum | Light, easy to shape |

| Brass | Shiny, good for appearance |

Lathe Maintenance and Safety Tips

Importance of regular maintenance for lathe longevity. Essential safety measures to follow while operating a lathe.

Taking care of your lathe keeps it happy and working well! Regular maintenance can extend its life, just like watering a plant helps it grow. Clean the parts often, and check for wear and tear. This way, you prevent mishaps that could turn your workspace into a scene from a slapstick comedy! Always wear safety gear like goggles and gloves. Remember, safety first, fun second—unless you’re telling jokes while measuring parts!

| Maintenance Tips | Safety Measures |

|---|---|

| Clean the lathe regularly | Wear safety goggles |

| Lubricate moving parts | Keep hands clear of the lathe |

| Check belts for wear | Use guards correctly |

Applications of Lathe Metal Shaping

Industries that utilize metal lathes (e.g., automotive, aerospace, manufacturing). Specific examples of projects made using lathe metal shaping techniques.

Many industries rely on lathe metal shaping. The automotive sector uses it to create parts like gears and shafts. The aerospace industry needs precision for airplane components. Manufacturing also benefits, making items from simple bolts to complex machinery. Here are some project examples:

- Custom engine parts for cars and trucks.

- Aircraft turbine blades that withstand high stress.

- Machine fittings used in factories.

These projects highlight the importance of metal lathes in modern production.

What industries use metal lathes?

Various fields utilize metal lathes. The automotive, aerospace, and manufacturing industries all benefit from this technology.

Purchasing Your First Metal Lathe

Factors to consider when buying a lathe (e.g., size, features, budget). Recommendations for brands and models for beginners.

Choosing your first metal lathe? Consider size, features, and budget. The lathe should fit in your workspace and suit your projects. Start small; it’s easier to manage and won’t take over your garage like that huge inflatable dinosaur you thought was a great idea. Look for features like variable speed and easy setup. Great beginner options include the Grizzly G8688 and the WEN 3420. Both are top picks and won’t break the bank!

| Model | Features | Price |

|---|---|---|

| Grizzly G8688 | Variable speed, Compact | Under $600 |

| WEN 3420 | Easy setup, Good support | About $500 |

Remember, each lathe part is important. Think about what you’ll make and choose wisely. Your new lathe should help you shape metal, not look like it’s fighting to escape your workbench!

Future Trends in Lathe Technology

Innovations in lathe technology (e.g., automation, integration with CAD). Impact of these trends on metal shaping processes and industries.

Imagine a world where lathes practically run themselves! Innovations in lathe technology are making this dream a reality. Automation is stepping in, meaning less time for workers and more time for tea breaks. Lathes can now integrate with CAD (Computer-Aided Design), which makes metal shaping easier and more precise. Industries are seeing big changes, as these smart machines help produce parts faster and with fewer mistakes. Get ready for lathes to take over the world, one shiny metal part at a time!

| Trend | Description | Impact |

|---|---|---|

| Automation | Machines that operate with little human help. | Faster production, fewer errors. |

| CAD Integration | Connecting design software directly to machines. | More accuracy and better designs. |

Conclusion

In summary, metal lathes are essential tools for shaping and crafting metal parts. They help you create precise shapes and designs. Understanding how these machines work will improve your skills and projects. Remember to practice safety and explore more about lathes. Discover more resources or try out a metalworking project to see your new knowledge in action!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Parts:

Sure! A lathe is a machine that shapes metal by spinning it around. You put a piece of metal on the lathe, and it turns while a tool cuts it into the right shape. Parts of a lathe include the headstock, tailstock, and cutting tool. Each part helps make the metal shape you want. It’s like making a wooden toy on a spinning tool, but for metal!

Sure! Please give me the question you’d like me to answer.

What Are The Essential Components Of A Metal Lathe, And How Do They Contribute To The Machining Process?

A metal lathe has several important parts. The bed is the main body that holds everything in place. The headstock spins the metal piece. The tailstock supports the other end of the metal. Finally, the carriage moves the cutting tool to shape the metal. Together, these parts help us turn a raw piece of metal into a finished piece.

How Do Different Types Of Lathe Tools Affect The Quality And Accuracy Of The Metal Shaping Process?

Different lathe tools can change how well metal is shaped. Some tools are sharp and can cut smoothly, while others are dull and might make rough edges. If you use the right tool for the job, you get better shapes and details. Good tools help make your project look nice and fit perfectly. Choosing the right tool is important for good work!

What Maintenance Practices Are Recommended For Keeping Metal Lathe Parts In Optimal Condition?

To keep your metal lathe parts in good shape, you should clean them regularly. Wipe away dust and oil after each use. Also, make sure to check the belts and gears for wear. Oil the moving parts to keep them running smoothly. Lastly, keep the machine in a dry place to prevent rust.

How Do You Choose The Appropriate Feed Rate And Cutting Speed For Various Metals When Using A Lathe?

To choose the right feed rate and cutting speed for different metals on a lathe, we need to know the metal type. Harder metals usually need a slower speed and slower feed rate. Softer metals can go faster and be fed quicker. We can also check charts or guides that help us find the best settings for each metal. Remember to always start slow and then adjust as needed!

What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Injuries?

When using a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothing to prevent getting caught. Make sure your tools are sharp and in good condition. Never reach into the machine while it’s running. Finally, keep the area around the lathe clean and free of clutter.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Parts:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that shapes metal by spinning it around. You put a piece of metal on the lathe, and it turns while a tool cuts it into the right shape. Parts of a lathe include the headstock, tailstock, and cutting tool. Each part helps make the metal shape you want. It’s like making a wooden toy on a spinning tool, but for metal!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Of A Metal Lathe, And How Do They Contribute To The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A metal lathe has several important parts. The bed is the main body that holds everything in place. The headstock spins the metal piece. The tailstock supports the other end of the metal. Finally, the carriage moves the cutting tool to shape the metal. Together, these parts help us turn a raw piece of metal into a finished piece.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Lathe Tools Affect The Quality And Accuracy Of The Metal Shaping Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different lathe tools can change how well metal is shaped. Some tools are sharp and can cut smoothly, while others are dull and might make rough edges. If you use the right tool for the job, you get better shapes and details. Good tools help make your project look nice and fit perfectly. Choosing the right tool is important for good work!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended For Keeping Metal Lathe Parts In Optimal Condition?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your metal lathe parts in good shape, you should clean them regularly. Wipe away dust and oil after each use. Also, make sure to check the belts and gears for wear. Oil the moving parts to keep them running smoothly. Lastly, keep the machine in a dry place to prevent rust.”}},{“@type”: “Question”,”name”: “How Do You Choose The Appropriate Feed Rate And Cutting Speed For Various Metals When Using A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To choose the right feed rate and cutting speed for different metals on a lathe, we need to know the metal type. Harder metals usually need a slower speed and slower feed rate. Softer metals can go faster and be fed quicker. We can also check charts or guides that help us find the best settings for each metal. Remember to always start slow and then adjust as needed!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Injuries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight clothing to prevent getting caught. Make sure your tools are sharp and in good condition. Never reach into the machine while it’s running. Finally, keep the area around the lathe clean and free of clutter.”}}]}