Have you ever wondered how things like car parts or tools are shaped? It all starts with machines that cut and mold metal. One of the coolest machines for this job is the metal lathe. This magical tool spins metal while carving it into different shapes.

Now, let’s talk about the quick change tool post. Do you know what it is? Imagine you’re making something, but you need to switch tools fast. The quick change tool post lets you do just that! You can change tools in just seconds, making the work much easier.

Using a lathe with a quick change tool post can make your projects faster and more fun. Picture yourself in a workshop, creating amazing pieces from metal. With this tool, you won’t waste time swapping tools. Instead, you can focus on bringing your ideas to life!

In this article, we will explore how lathe metal shaping works and dive deeper into the benefits of the quick change tool post. Are you ready to unlock your creativity and learn some cool tips? Let’s get started!

Lathe Metal Shaping: Metal Lathe Quick Change Tool Post Guide

Understanding the Metal Lathe Quick Change Tool Post

The metal lathe quick change tool post makes machining easier and more efficient. It allows users to switch between different tools quickly, reducing downtime. Imagine working on a project and, instead of fumbling with tools, you can seamlessly change them. This tool post is vital for those seeking precision and speed in metal shaping. Did you know that many professionals rely on it to complete complex tasks faster? It’s a game changer in metalworking!

Understanding Metal Lathes

Definition and purpose of a metal lathe. Key components of a metal lathe.

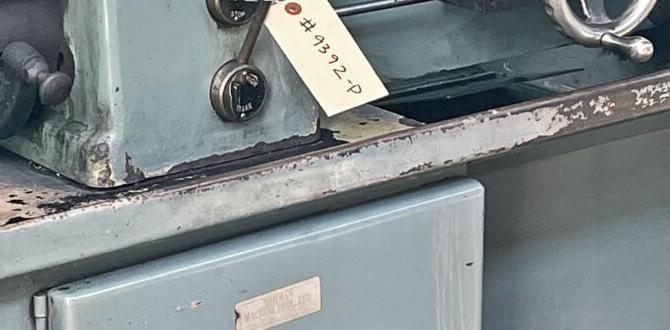

A metal lathe is a machine that shapes metal into precise parts. Think of it as a fancy tool that spins metal like a merry-go-round while cutting it into different shapes. This machine is perfect for creating anything from bolts to beautiful sculptures. Key parts include the headstock, tailstock, bed, and tool post. Each piece plays a special role in making smooth and accurate cuts. Remember, without the quick change tool post, changing tools would take ages—like waiting for milk to boil!

| Component | Purpose |

|---|---|

| Headstock | Holds the spindle and powers the machine. |

| Tailstock | Supports the other end of the workpiece. |

| Bed | Base where everything sits and stays steady. |

| Tool Post | Holds the cutting tool securely in place. |

History and Evolution of Metal Lathes

Milestones in lathe technology. Advancements leading to modern lathes.

The journey of metal lathes is quite fascinating! It all began in ancient Egypt around 1300 BC with simple machines, like the bow lathe. Fast forward to the Middle Ages, and folks invented the more advanced slide rest lathe. This was like upgrading from a bicycle to a sports car! By the 19th century, we saw screw-cutting lathes, which allowed for precise metal shaping. Today’s lathes, equipped with quick change tool posts, make work faster and easier. In fact, the evolution of these tools has turned many into metal-morphing superheroes!

| Milestone | Year |

|---|---|

| Ancient Bow Lathe | 1300 BC |

| Slide Rest Lathe | Middle Ages |

| Screw-Cutting Lathe | 19th Century |

| Modern Lathe with Quick Change Tool Post | 21st Century |

Benefits of Quick Change Tool Posts

Explanation of what a quick change tool post is. Advantages of using quick change tool posts in metalworking.

A quick change tool post lets you switch tools on a lathe quickly. It’s like having a magic wand in metalworking! Instead of wasting time swapping tools, you can get back to shaping metal faster. This means less downtime and more productivity. Plus, it can help you create precise cuts every time. Think of it as your trusty sidekick that makes every project smoother. Who wouldn’t want a helper that works as fast as you do?

| Advantages of Quick Change Tool Posts | Details |

|---|---|

| Speed | Quick tool swapping saves time. |

| Accuracy | Helps achieve precise cuts consistently. |

| Efficiency | More work done in less time! |

Setting Up a Quick Change Tool Post

Stepbystep installation guide. Tips for ensuring precision and accuracy in setup.

Installing a quick change tool post can feel like assembling a puzzle, but it’s easier than it sounds! Start by carefully removing the old tool post. Next, place the new tool post on the lathe and tighten it down—snug like your favorite pair of socks. Make sure it’s level using a bubble level; a tilted tool is like a tilted pizza, and no one wants that! Here’s a handy checklist:

| Step | Action |

|---|---|

| 1 | Remove old tool post |

| 2 | Place new tool post |

| 3 | Tighten securely |

| 4 | Check for level |

Follow these steps for accurate setup!

Choosing the Right Tooling for Your Metal Lathe

Criteria for selecting tools compatible with quick change tool posts. Popular tooling options and their applications.

Selecting tools for your metal lathe can be as tricky as choosing the right toppings for a pizza. You want tools that fit well with your quick change tool post. Look for compatibility, ease of use, and the kind of work you’ll do. Popular options include turning tools, boring bars, and parting tools. Each has its special job, kind of like a superhero with a unique power!

| Tool | Application |

|---|---|

| Turning Tool | Great for shaping the outside of a workpiece. |

| Boring Bar | Perfect for enlarging holes inside materials. |

| Parting Tool | Excellent for cutting off pieces from a larger block. |

Remember, the right tool will make your project easier and more fun. Happy lathe-ing!

Techniques for Shaping Metal with Lathe

Essential metal shaping techniques. Best practices for achieving desired shapes and finishes.

Shaping metal with a lathe can be fun and creative. Many essential techniques help to make cool shapes. Here are a few key tips:

- Cutting speed: Adjust the speed for different metals.

- Tools: Use sharp tools for smooth cuts.

- Feed rate: Control how fast the tool moves.

- Finishing: Sand the edges for a polished look.

When using these techniques, you can achieve shapes and finishes that look great. Take your time, and practice makes perfect!

What are some basic techniques for using a lathe?

Some basic techniques include adjusting the speed and choosing the right tools for the job. Make sure to maintain a steady hand and focus on smooth movements.

What tools can help during metal shaping?

- Quick change tool post: This allows easy tool swaps.

- Cutting tools: These are essential for shaping.

Practice these methods, and you’ll improve your skills quickly!

Common Mistakes to Avoid with Metal Lathes

List of frequent errors made by beginners. Tips for troubleshooting common issues.

Many beginners make simple mistakes with metal lathes that can turn fun into frustration! One common error is skipping the setup steps. Always check your tools before starting. Another mistake is not using the right speed for the material. If it sounds like a cat in a blender, you might want to slow down!

Here’s a quick tip table to help you:

| Error | Tip |

|---|---|

| Wrong tool height | Adjust it to the centerline. |

| Letting chips pile up | Clear them regularly for a smooth cut. |

| Ignoring safety gear | Always wear goggles and gloves! |

Fixing these mistakes can make your lathe time much smoother. So, keep calm and turn on!

Maintaining Your Metal Lathe for Longevity

Routine maintenance procedures. Signs that indicate parts may need repair or replacement.

Keeping your metal lathe in tip-top shape is crucial for smooth operations and long life. Regularly clean it and lubricate the moving parts. This routine maintenance can help catch issues before they become big problems. Watch out for signs like strange noises, uneven cuts, or an inability to hold tools firmly. These may mean parts need repair or replacement. A little preventive care goes a long way, like brushing your teeth to avoid the dentist! Here’s a handy table to guide you:

| Routine Maintenance | Signs of Issues |

|---|---|

| Clean and lubricate weekly | Strange noises while operating |

| Check alignment every month | Uneven cuts on the material |

| Inspect belts and gears | Difficulty holding tools |

Resources for Further Learning

Recommended books and online courses for mastering lathe techniques. Community forums and support groups for lathe enthusiasts.

Learning about lathes can be fun and easy! Check out these resources to help you. Good books can teach you new techniques. Try online courses to watch videos and learn at your pace. Don’t forget the community forums! They have many friendly people who share tips and advice. Here are some suggestions:

- Books: “Lathe Basics” and “Machining Made Easy.”

- Online Courses: Websites like Udemy and Coursera offer great classes.

- Forums: Visit the ‘Machinist Forum’ for helpful discussions.

What are the best books for mastering lathe techniques?

“Lathe Basics” and “Lathe Operations” are highly recommended. They cover everything you need to know about using a lathe correctly.

Conclusion

In summary, a lathe metal shapes materials smoothly and accurately. The metal lathe is powerful for various projects. A quick change tool post saves time by allowing tool switches without delays. We can build better projects by using these tools effectively. If you’re interested, explore more about lathe techniques and tools to improve your skills. Happy cutting!

FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Quick Change Tool Posts:

Sure! A lathe is a machine that shapes metal by spinning it around. You can use different tools to cut and shape the metal. A quick change tool post helps you switch tools easily, making work faster. It’s like using different crayons when drawing. With a quick change tool, you can make cool shapes without wasting time!

Sure! Go ahead and ask your question, and I’ll be happy to help!

What Are The Primary Advantages Of Using A Quick Change Tool Post Over A Standard Tool Post On A Metal Lathe?

Using a quick change tool post is much faster than a standard tool post. You can switch tools quickly, which saves time. This means you can finish your work faster. It also helps you keep your tools more organized. Plus, it makes using the lathe easier and more fun!

How Does The Design Of A Quick Change Tool Post Enhance The Efficiency Of Machining Operations?

A quick change tool post helps you swap tools faster while working on a machine. Instead of taking a long time to switch tools, you can do it in a minute or two. This means you spend more time making your project and less time changing tools. It makes everything quicker and helps you finish your work better.

What Types Of Tooling Can Be Used With A Quick Change Tool Post, And How Do They Differ From Traditional Tooling Setups?

You can use different tools with a quick change tool post, like lathes, drills, and chisels. These tools are easy to swap out. You simply change one tool for another without much fuss. Unlike traditional setups, you don’t need to spend a lot of time adjusting everything. This makes work faster and less frustrating!

What Are The Steps Involved In Properly Installing And Aligning A Quick Change Tool Post On A Lathe?

To install a quick change tool post on a lathe, you first need to remove the old tool holder. Then, clean the surface where the new tool post will go. Next, place the quick change tool post on the lathe and secure it tightly using bolts. After that, you should adjust the tool so it sits at the right height for your work. Finally, make sure everything is tight and check that the tool moves correctly.

How Can Users Troubleshoot Common Issues Encountered With Quick Change Tool Posts, Such As Tool Alignment Or Stability During Operation?

To fix problems with quick change tool posts, start by checking if the tool is lined up straight. You can do this by loosening and adjusting the tool. Make sure it’s tight and secure when you put it back. If the tool shakes or moves, check the clamps and bolts to see if they are loose. Lastly, you can try using a different tool to see if it works better.