Have you ever wondered how metal objects are shaped with precision? One tool plays a big role in this process—the lathe. A lathe is like a magic wand for metalworkers. It spins metal and lets them carve it into amazing shapes. But what about the tailstock? It’s a special part of the lathe that helps hold the metal steady.

Imagine you’re building a model rocket. You want your parts to fit perfectly. The tailstock keeps the metal in place while you shape it. This is very helpful for making sure everything works just right. Did you know that using a metal lathe can help you create both small and large projects? It’s true!

Whether you’re a hobbyist or a pro, knowing about the lathe and its tailstock is exciting. Let’s dive into how this fantastic tool works and why it’s so important for shaping metal. You might discover something new and useful!

Lathe Metal Shaping: Understanding Metal Lathe Tailstock

Understanding the Metal Lathe Tailstock

The tailstock is an essential part of a metal lathe. It supports the other end of the workpiece, keeping it stable during shaping. Without a tailstock, precision would suffer. Did you know that tailstocks can also hold tools like drills? This feature allows for more versatile operations. When using a metal lathe, learning to adjust the tailstock properly can significantly improve your projects. It’s a small part, but it makes a big difference!

Components of a Metal Lathe

Description of major parts including bed, headstock, and tailstock. Importance of each component in the functioning of the lathe.

A metal lathe is made of several main parts that work together. Each part plays an important role. Let’s break it down:

- Bed: The bed supports the entire lathe. It keeps everything in place.

- Headstock: This part holds the spindle. It spins the material that gets shaped.

- Tailstock: Located opposite the headstock, the tailstock helps stabilize and support the workpiece.

Each component is crucial for smooth operation. Without them, the lathe cannot shape metal properly.

What is the function of the tailstock on a metal lathe?

The tailstock holds the other end of the workpiece. It allows for precise shaping and helps keep everything stable during the process. This stability is key to getting a good finish.

The Role of the Tailstock in Metal Shaping

Functions of the tailstock and its impact on precision. How the tailstock supports workpieces during machining.

The tailstock is a key part of a metal lathe. It holds workpieces firmly while they are shaped. This helps keep the object steady. When the tailstock is used properly, it improves precision. Here are its main functions:

- Supports long pieces during cutting.

- Adjusts the position of the workpiece.

- Holds tools for drilling and tapering.

By using the tailstock, workers can make cleaner cuts. Machines run smoother, and the final product looks better.

What is the purpose of using a tailstock?

The tailstock provides necessary support and stability, ensuring that workpieces remain aligned during machining. This improves both accuracy and safety while working with metal lathes.

Types of Tailstocks and Their Applications

Fixed vs. movable tailstocks. Specialized tailstocks for specific tasks.

Tailstocks are important parts of a lathe that help shape metal. There are two main types: fixed and movable. Fixed tailstocks stay put, while movable ones can slide to fit different sizes of workpieces. Think of them like a pair of adjustable pants for your metal! Some tailstocks are made for special tasks too. For example, a taper tailstock helps create pointed ends. This way, you get the perfect shape every time!

| Type of Tailstock | Application |

|---|---|

| Fixed Tailstock | Stays in one spot for standard jobs. |

| Movable Tailstock | Slides to fit different sizes. |

| Taper Tailstock | Creates pointed ends for special projects. |

Setting up the Tailstock for Optimal Performance

Stepbystep guide on aligning and calibrating the tailstock. Common mistakes to avoid while setting up.

Start by adjusting the tailstock carefully. Make sure it lines up with the spindle. Use the following steps for best results:

- Check alignment with a dial indicator.

- Tighten the tailstock bolts firmly.

- Test it by making a small cut.

Watch out for these common mistakes:

- Don’t overtighten bolts, as this can damage parts.

- Avoid misaligning the tailstock, which causes bad cuts.

- Calibrate regularly to maintain accuracy.

How do I align the tailstock properly?

To align the tailstock properly, check the spindle alignment using a dial indicator. Make sure everything is tight and test the alignment with a small cut on your workpiece.

Troubleshooting Tailstock Issues

Identifying common problems with the tailstock. Solutions and maintenance tips for a reliable tailstock operation.

Tailstock problems can slow down your work on a metal lathe. Common issues include misalignment, stuck parts, and backlash. Regular maintenance helps keep your tailstock running well. Try these tips:

- Check for tightness in screws and adjust them.

- Clean any debris that may cause problems.

- Lubricate moving parts to ensure smooth action.

- Align the tailstock with the main spindle for accuracy.

If you follow these steps, your tailstock will operate reliably.

How can I fix common tailstock problems?

To fix tailstock issues, start by checking for looseness or wear. Clean it regularly and keep it well-lubricated. Adjust the alignment as needed. This simple care can prevent bigger problems later.

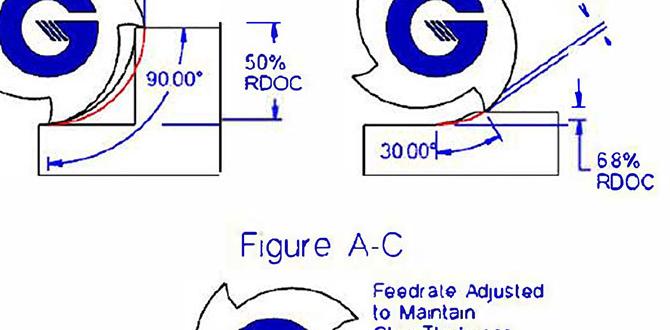

Advanced Techniques for Metal Shaping with Tailstock

Utilizing the tailstock for complex shapes and designs. Tips for enhancing creativity and efficiency using the tailstock.

The tailstock is a useful part of the lathe. It can help you create complex shapes and neat designs. By adjusting it, you can better support your workpiece. This makes your creations more detailed and smooth. To boost your creativity and efficiency, try these tips:

- Experiment with different speeds for unique shapes.

- Use steady pressure for accurate results.

- Practice using various tools in the tailstock.

These practices will help you become a better metal worker and inspire new ideas.

How can I make better shapes with the tailstock?

To make better shapes, use the tailstock to hold your piece firmly. This helps you shape it easily. Also, try adjusting the tailstock for different angles. This adds more creativity to your work.

Safety Best Practices When Using Lathe Machines

Essential safety measures to follow while operating a lathe. Importance of personal protective equipment (PPE) in metalworking.

Using a lathe machine can be fun, but safety comes first! Always wear personal protective equipment (PPE) like goggles and gloves. They make you look cool while keeping you safe from flying chips. Did you know? More than half of machine injuries come from not using PPE!

| Essential Safety Measures | Importance of PPE |

|---|---|

| Keep your work area clean. | Protects you from debris. |

| Secure loose clothing or hair. | Prevents snagging and accidents. |

| Always use the guards on the machine. | Reduces risk of injury. |

Remember, safety isn’t just smart; it’s essential. Follow these tips and you’ll stay safe while crafting awesome metal shapes. So, let’s lathe and laugh, but let’s keep our fingers intact!

Conclusion

In conclusion, the tailstock is a vital part of a metal lathe. It helps support the workpiece and allows you to make precise cuts. Understanding how to use it will improve your metal shaping skills. So, grab a lathe, practice with the tailstock, and explore more resources to enhance your projects! Happy shaping!

FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping, Specifically Focusing On The Tailstock Of A Metal Lathe:

The tailstock is a part of a metal lathe. It helps hold the other end of the piece you’re working on. You can adjust it to fit different sizes. This makes it easier for you to shape metal safely. The tailstock is important for keeping your work straight and steady.

Of course! Please provide the question you’d like me to answer.

What Is The Primary Function Of The Tailstock In A Metal Lathe, And How Does It Contribute To The Shaping Process?

The tailstock on a metal lathe holds tools and pieces of metal steady while we work. It helps us cut and shape the metal evenly. We can also use it to support longer pieces, so they don’t wobble. Overall, the tailstock makes it easier to create smooth and precise shapes.

How Do You Adjust The Tailstock To Accommodate Different Workpiece Lengths And Diameters?

To adjust the tailstock, you first unlock it. Then, you can slide it along the lathe. Move it closer or further away depending on the workpiece length. For diameter, you can change the center point or tool used. Make sure everything is tight before you start working!

What Types Of Tools Can Be Mounted On The Tailstock For Specific Operations, Such As Drilling Or Reaming?

You can attach different tools to the tailstock of a lathe. For drilling, you can use a drill bit. For reaming, a reamer is needed to make holes smoother. You might also use a center for holding the workpiece steady. These tools help you make better shapes and holes in your projects.

How Does The Alignment Of The Tailstock Affect The Precision And Accuracy Of The Machining Process?

The tailstock helps hold the piece we are working on. If it’s not lined up right, our piece can wobble. This wobbling makes it hard to cut or shape the material correctly. When we align the tailstock properly, we get better and more exact results. So, good alignment is super important for our work!

What Are Common Maintenance Practices For Ensuring The Tailstock Remains In Good Working Condition On A Metal Lathe?

To keep the tailstock of a metal lathe in good shape, you should clean it regularly. Wipe off dirt and oil with a soft cloth. Check for any loose parts and tighten them. You also need to apply oil or grease to keep everything running smoothly. Finally, make sure the tailstock moves easily along the bed of the lathe.