Have you ever wondered how metal objects take shape? It’s all thanks to a powerful tool called the metal lathe. This amazing machine can turn a block of metal into something useful and cool, like a beautiful bowl or a sturdy pipe.

Metal shaping is an art, and the tools we use play a crucial role. Imagine a sculptor carefully chiseling away at a block of marble. Similarly, a lathe uses metal lathe tools to cut, shape, and polish metal. But how does it all work?

Many might think that only experts use such tools. But with a little practice, anyone can learn to create amazing projects. The joy of seeing raw metal transformed into something special is truly rewarding!

What if you could make your own gadgets or repairs? With the right knowledge of metal lathes, you can! Join us as we dive into the fascinating world of metal shaping and see what you can create!

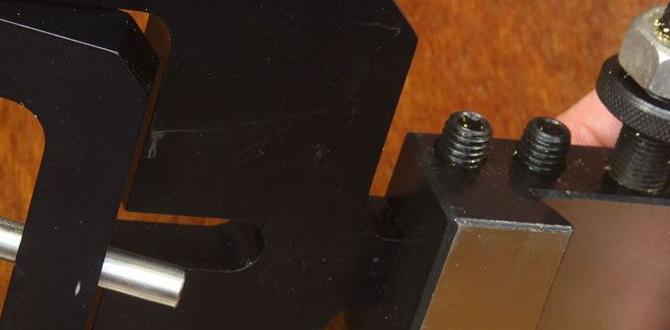

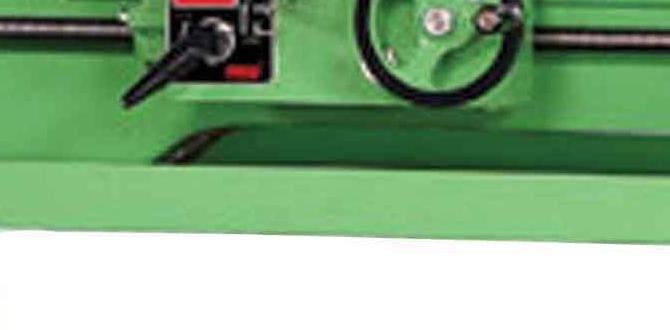

Lathe Metal Shaping: Essential Metal Lathe Tools Explained — Metal Shaping Is A Crucial Process In Manufacturing And Fabrication, And One Of The Primary Tools Used For This Purpose Is The Metal Lathe. Understanding How To Use Lathe Metal Shaping Techniques And The Various Metal Lathe Tools Available Is Essential For Both Amateur And Professional Machinists. What Is A Metal Lathe? A Metal Lathe Is A Machine Tool That Rotates A Workpiece Against A Stationary Cutting Tool In Order To Shape It Into The Desired Form. This Process Is Called Turning, And It Is One Of The Most Common Methods Of Shaping Metal. Metal Lathes Are Versatile And Can Be Used To Create A Variety Of Shapes And Sizes, Making Them Indispensable In Workshops, Factories, And Educational Settings. Key Components Of Metal Lathe Tools Understanding The Essential Components Of Metal Lathe Tools Can Greatly Enhance Your Proficiency In Lathe Metal Shaping. Here Are Some Of The Key Parts: 1. **Headstock**: Contains The Spindle And Motor, Which Drive The Rotation Of The Workpiece. 2. **Tailstock**: Supports The Opposite End Of The Workpiece And Can Hold Drill Bits Or Live Centers For Additional Operations. 3. **Bed**: The Bed Is The Base Of The Lathe That Provides Stability And Support For The Headstock And Tailstock. 4. **Carriage**: Moves The Cutting Tool Along The Length Of The Workpiece. 5. **Tool Post**: Holds The Cutting Tool In Place And Allows For Adjustments. Types Of Metal Lathe Tools There Are Several Tools Specifically Designed For Use On A Metal Lathe, Each Serving Different Purposes In The Lathe Metal Shaping Process: – **Cutting Tools**: These Tools Remove Material From The Workpiece And Are Usually Made Of High-Speed Steel (Hss) Or Carbide. – **Turning Tools**: Specifically Designed For Creating Cylindrical Shapes. – **Boring Tools**: Used For Enlarging Existing Holes In A Workpiece. – **Threading Tools**: Allow For The Creation Of Threads For Screws And Bolts. – **Facing Tools**: Used For Flattening The End Of A Workpiece. Applications Of Lathe Metal Shaping Lathe Metal Shaping Is Widely Used Across Various Industries, Including: – **Automotive Manufacturing**: Creating Precision Components For Vehicles. – **Aerospace Engineering**: Producing Parts That Require High Tolerances And Quality. – **Machinery Production**: Making Custom Machine Components. Conclusion Mastering Lathe Metal Shaping Using The Right Metal Lathe Tools Can Lead To Increased Efficiency And Precision In Your Projects. By Understanding The Machine’S Components And The Various Types Of Tools Available, You’Ll Be Well-Equipped To Tackle A Range Of Metalworking Tasks With Confidence. Whether You’Re A Hobbyist Or A Seasoned Machinist, Investing Time In Learning About Lathe Metal Shaping Can Vastly Improve Your Skills And Output.

Lathe Metal Shaping: Understanding Metal Lathe Tools

Using a metal lathe can transform raw materials into precise shapes. Imagine turning a plain piece of metal into a beautiful vase or a functional tool! Metal lathe tools are key to this process. They help create smooth curves and exact dimensions. Did you know that lathes have been shaping metal for hundreds of years? This ancient technique is still essential in modern workshops today. Learning about metal lathes opens the door to endless creative projects!

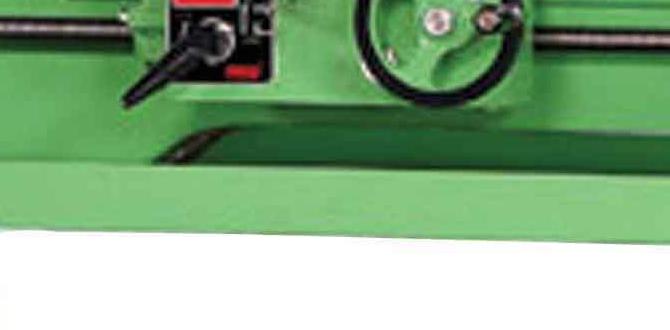

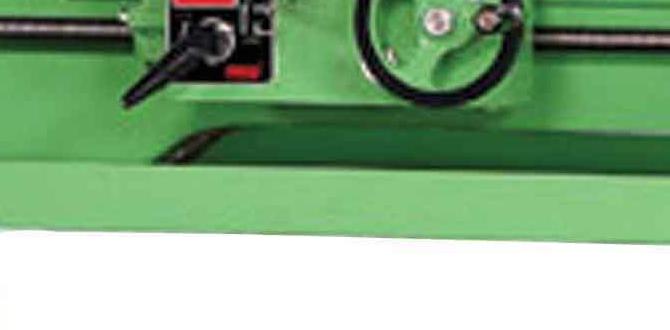

Understanding Lathe Machines

Definition and purpose of lathe machines. Types of lathes and their specific uses.

Lathe machines are tools that shape metal, wood, or plastic. They spin the material while a cutting tool carves it into desired shapes. This skill is useful for making various objects like bolts, handles, and even artistic pieces. There are several types of lathes, each serving a specific purpose:

- Wood Lathe: Used for turning wood into furniture or crafts.

- Metal Lathe: Perfect for shaping metal parts in machines.

- Vertical Lathe: Designed for large items; it rotates them vertically.

Understanding these machines helps in creating precise and beautiful shapes. They are essential in factories and workshops around the world.

What is the main purpose of a lathe machine?

The main purpose of a lathe machine is to shape materials like metal, wood, or plastic into specific forms. They help create items with smooth surfaces and well-defined shapes.

Key Features of Lathes

- High precision cutting.

- Versatility across different materials.

- Ability to create complex shapes.

Lathe Operation Techniques

Basic setup and calibration of the lathe. Safe operation practices to ensure precision and safety.

Before you start, make sure your lathe is set up correctly. Check the tools and adjust the settings. It’s like tuning your bike before a race; you want everything to run smoothly. Safety is crucial. Always wear goggles and keep your fingers away from moving parts. It’s not a game of “How close can I get?” Remember, precision is key in metal shaping!

| Setup Steps | Safety Tips |

|---|---|

| 1. Align the tool correctly. | Wear safety glasses. |

| 2. Check RPM settings. | Keep hands clear of moving parts. |

| 3. Secure the workpiece. | Don’t wear loose clothing. |

Following these simple steps can prevent mishaps. Remember, it’s not all about speed, but accuracy and safety. As they say, “A careful worker is a happy worker!”

Common Metal Shaping Projects with a Lathe

Examples of projects (spindles, bushings, etc.). Tips for selecting projects based on skill level.

A lathe can create many cool projects. Some popular ideas are spindles, bushings, and decorative bowls. These projects are suitable for different skill levels. Beginners might start with simple bushings. Intermediate users can try making spindles. Advanced makers might enjoy crafting intricate bowls. Choose a project that feels fun and matches your skill.

What are some good projects for beginners using a lathe?

Some good projects include simple wooden toys or small bowls. They help build basic skills while being fun!

Tips for Choosing Projects:

- Pick a project that excites you.

- Make sure you have the right tools.

- Start small and build up your skills.

Maintenance of Metal Lathe Tools

Routine maintenance practices for longevity. Troubleshooting common issues with lathe machines.

Taking care of your metal lathe tools keeps them working well. Regular checks help catch problems early. Here are some tips for routine maintenance:

- Clean the machine after each use.

- Lubricate moving parts often.

- Check belts for wear and tear.

- Inspect for any loose bolts.

Common issues with lathes include noise and vibrations. Look for stuck parts or low lubrication. Address these quickly to avoid bigger problems.

How can you troubleshoot lathe machines?

If you face troubles, look for: worn belts, loose screws, or dirty mechanisms. Fixing these can make your machine work like new again!

Choosing the Right Metal Lathe for Your Needs

Factors to consider when purchasing a lathe. Comparison of popular brands and models.

Buying a metal lathe can be exciting but also tricky. Many things matter before you decide. First, think about what you will make. Size and power are important. Check the quality of the tools. Popular brands often offer good features. Here are some factors to look for:

- Size: Make sure it fits your space.

- Speed: Faster lathes work better for different materials.

- Budget: Find one that fits your budget while meeting your needs.

- Brand: Research reliable brands.

Brands like Grizzly and Jet are well-known for quality. Each model has different features. So, take your time and choose wisely!

What should I consider before choosing a lathe?

Before choosing a lathe, consider size, speed, and budget. Each factor affects how well you can work with metal. Finding a lathe that matches your needs is key!

Resources for Further Learning on Metal Shaping

Recommended books, websites, and online courses. Industry forums and communities for metal lathe enthusiasts.

Learning about metal shaping can be fun! There are many great resources to help you dive deeper. Here are some recommended options:

- Books: Look for titles like “Metalworking 101” for basics.

- Websites: Check out the Metal Shaping Forum for tips and tricks.

- Online courses: Websites like Udemy offer courses on using metal lathe tools.

- Communities: Join groups on social media to connect with other metal lathe enthusiasts.

These resources can make learning easier and more enjoyable!

What are some good books for learning metal shaping?

“Metalworking 101” and “The Complete Manual of Woodworking” are excellent choices. They provide easy-to-follow instructions and engaging illustrations that are perfect for beginners.

Conclusion

In summary, metal lathes are powerful tools that help shape metal into precise forms. Using the right lathe tools is crucial for achieving great results. You can create many projects with these tools, from simple to complex items. Explore more about metal lathes and practice using them to enhance your skills. Start experimenting and enjoy the process of making!

FAQs

Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Tools:

A lathe is a machine that helps shape metal. You put metal on the lathe, and it spins around. As it spins, you use tools to cut and smooth the metal. This makes different shapes, like cylinders or cones. It’s a fun way to create metal parts!

Sure! Please provide the question you’d like me to answer.

What Are The Primary Types Of Tools Used In Metal Lathes For Shaping And Cutting Materials?

In metal lathes, we use different tools to shape and cut materials. The main tools are cutting tools, which slice through the metal. There are also drilling tools that make holes. Then, we have facing tools, which smooth the ends of metal pieces. Each tool helps us create shapes and objects out of metal.

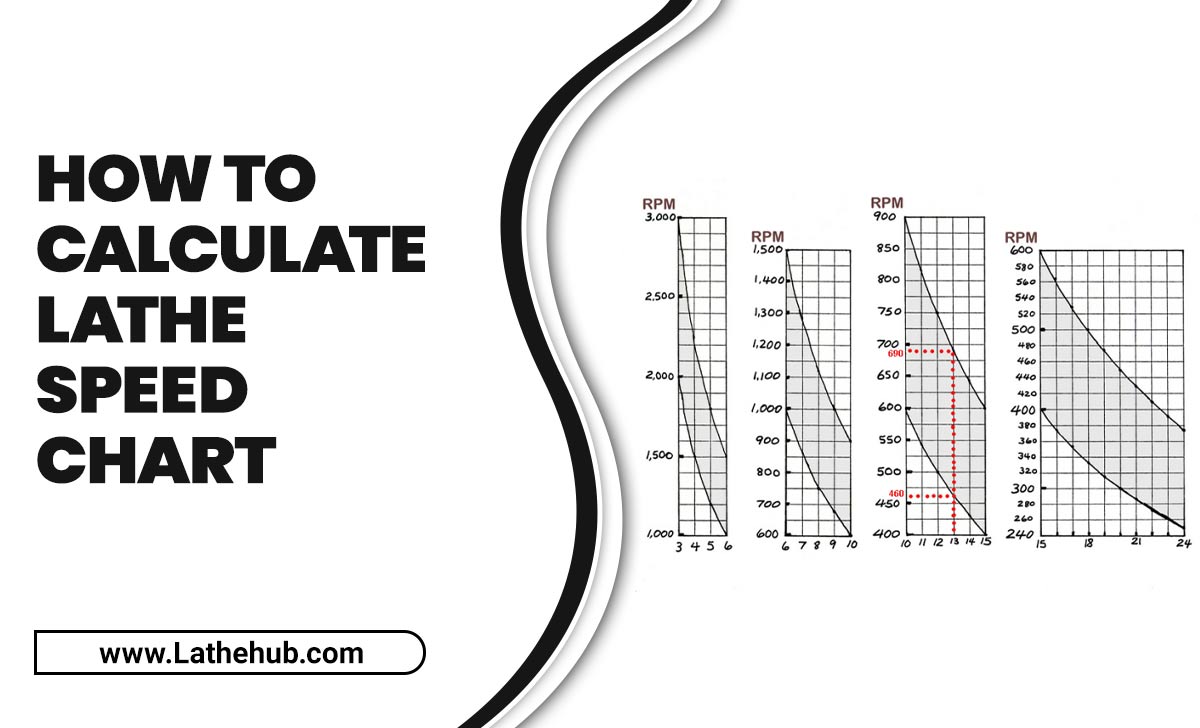

How Do You Determine The Appropriate Cutting Speed And Feed Rate For Different Metals When Using A Lathe?

To find the right cutting speed and feed rate for different metals on a lathe, you can look up charts. These charts give specific numbers for each metal type. You also can start with slower speeds to see how the metal behaves. As you gain experience, you will get a better feel for what works best. Remember to check if the metal is soft or hard, as that changes the settings.

What Safety Precautions Should Be Taken When Operating A Metal Lathe?

When using a metal lathe, always wear safety glasses to protect your eyes. Make sure to tie back long hair and avoid loose clothing, as they can get caught in the machine. Keep your fingers away from moving parts to stay safe. Always check that tools and parts are secure before starting the lathe. Lastly, never rush; take your time to work carefully!

How Do You Perform Maintenance And Calibration On A Metal Lathe To Ensure Precision In Machining?

To keep a metal lathe working well, you need to check it often. First, you clean it to remove dust and dirt. Then, you check the gears and belts for wear and tear. Next, you adjust the settings to make sure it cuts straight. Finally, you test it with a small piece of metal to check if it works right.

What Are The Differences Between Manual And Cnc Lathes In Terms Of Metal Shaping Capabilities And Ease Of Use?

Manual lathes need you to control everything by hand. They are great for simple shapes. CNC lathes, which stands for Computer Numerical Control lathes, do much of the work for you. They can make complex shapes and are easier to use once set up. You can repeat the same design perfectly with a CNC lathe!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe is a machine that helps shape metal. You put metal on the lathe, and it spins around. As it spins, you use tools to cut and smooth the metal. This makes different shapes, like cylinders or cones. It’s a fun way to create metal parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Primary Types Of Tools Used In Metal Lathes For Shaping And Cutting Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathes, we use different tools to shape and cut materials. The main tools are cutting tools, which slice through the metal. There are also drilling tools that make holes. Then, we have facing tools, which smooth the ends of metal pieces. Each tool helps us create shapes and objects out of metal.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Cutting Speed And Feed Rate For Different Metals When Using A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right cutting speed and feed rate for different metals on a lathe, you can look up charts. These charts give specific numbers for each metal type. You also can start with slower speeds to see how the metal behaves. As you gain experience, you will get a better feel for what works best. Remember to check if the metal is soft or hard, as that changes the settings.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety glasses to protect your eyes. Make sure to tie back long hair and avoid loose clothing, as they can get caught in the machine. Keep your fingers away from moving parts to stay safe. Always check that tools and parts are secure before starting the lathe. Lastly, never rush; take your time to work carefully!”}},{“@type”: “Question”,”name”: “How Do You Perform Maintenance And Calibration On A Metal Lathe To Ensure Precision In Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, you need to check it often. First, you clean it to remove dust and dirt. Then, you check the gears and belts for wear and tear. Next, you adjust the settings to make sure it cuts straight. Finally, you test it with a small piece of metal to check if it works right.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Manual And Cnc Lathes In Terms Of Metal Shaping Capabilities And Ease Of Use?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Manual lathes need you to control everything by hand. They are great for simple shapes. CNC lathes, which stands for Computer Numerical Control lathes, do much of the work for you. They can make complex shapes and are easier to use once set up. You can repeat the same design perfectly with a CNC lathe!”}}]}