Have you ever wondered how metal shapes into useful parts? The magic often happens on a metal lathe. With a metal lathe, you can create things like bicycle parts, car engine components, or even tools. But how does such a machine work?

Many people don’t realize that understanding the lathe metal shaping process is simpler than it seems. It’s like building a model, but on a larger scale! You might ask, “What about the wiring?” That’s where a lathe metal shaping metal lathe wiring diagram comes in.

A wiring diagram shows you how to connect the parts. It’s a bit like following a recipe. You need the right steps to cook up something amazing. Did you know that the first lathes were made over 2000 years ago? They were simple wooden machines but laid the foundation for today’s advanced tools.

In this article, we will explore the lathe and its wiring. You’ll see how easy it can be to understand. Let’s dive into the exciting world of metal shaping!

Lathe Metal Shaping: Essential Metal Lathe Wiring Diagram

Lathe Metal Shaping: Understanding Metal Lathe Wiring Diagrams

Metal lathes are fascinating tools that shape metal into precise forms. A wiring diagram shows how to connect the electrical components. Knowing this can help you troubleshoot issues or make upgrades. Have you ever wondered how machines work? Learning about lathe wiring can spark deeper interest in engineering. With the right connections, your lathe can perform better. Dive deeper into the world of metal shaping and watch your creativity come alive!

Understanding Metal Lathes

Definition and function of metal lathes. Importance in metal shaping processes.

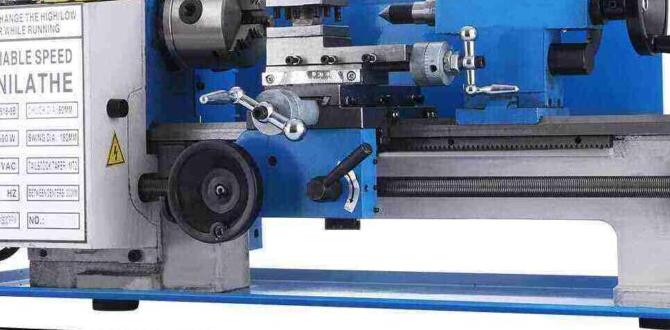

Metal lathes are machines that shape metal into useful forms. They work by rotating the metal while cutting tools shape it. This process is essential for creating parts in cars, airplanes, and machinery. Metal lathes make precise pieces that fit together perfectly. Without them, manufacturing would be slower and less accurate.

- Definition: Machines that spin metal for shaping.

- Function: Cuts metal into specific shapes.

- Importance: Vital for making parts in various industries.

Why are metal lathes important?

They ensure accuracy, speed up production, and reduce waste in manufacturing processes.

Types of Metal Lathes

Description of different lathe types: engine lathes, turret lathes, CNC lathes. Pros and cons of each type for various applications.

Metal lathes are important tools for shaping metal. There are different types, each with unique features. Here are three common types:

- Engine Lathes: Great for general work. They are versatile but need more skill to use.

- Turret Lathes: These can automate tasks. They are fast, but they can be tricky to maintain.

- CNC Lathes: Computer-controlled for high precision. They are efficient, but they can be expensive.

Choosing the right lathe depends on your needs. Each one has its pros and cons.

What is the best type of metal lathe for beginners?

Engine lathes are often best for new users because they are easier to operate. This makes learning about lathe work simple and fun.

Metal Lathe Wiring Basics

Explanation of electrical components in a metal lathe. Safety precautions for wiring and electrical setup.

Understanding a metal lathe’s wiring is important for safety and efficiency. The main electrical parts include the motor, switches, and circuit boards. Each component works together to help shape metal. Always follow safety rules when wiring:

- Disconnect power before starting work.

- Use insulated tools to prevent shocks.

- Check connections for signs of wear.

Keeping these precautions in mind creates a safe workspace for everyone. Remember, safety first!

What are the main electrical components of a metal lathe?

The common components of a metal lathe are the motor, switch, and circuit board.

Why is safety important in metal lathe wiring?

Safety is crucial to prevent accidents and damage to equipment. Always follow guidelines while working with electricity!

Creating a Metal Lathe Wiring Diagram

Stepbystep guide to drafting a wiring diagram. Tools and software that can aid in diagram creation.

Making a wiring diagram for a lathe can be fun and informative. Start by gathering tools like a pencil, paper, and a ruler. You can also use software such as Microsoft Visio or Lucidchart. Follow these simple steps:

- Identify all parts of the lathe.

- Map the connections between components.

- Draw the layout clearly and label each part.

- Review the diagram for any mistakes.

This process helps you understand how your lathe works. It’s like creating a treasure map for building your machine!

What tools are best for creating a wiring diagram?

Tools like Microsoft Visio, Lucidchart, and simple graph paper can help. They make it easy to create clear diagrams with details.

Common Wiring Issues and Solutions

Identification of frequent wiring problems in metal lathes. Troubleshooting tips for common issues.

Wiring issues in metal lathes can slow down your work. Identifying these problems helps you fix them quickly. Common issues include:

- Loose connections

- Frayed wires

- Burned-out motors

For troubleshooting, check for:

- Secure connections

- Damaged wires

- Working power source

Regular checks can keep your metal lathe running smoothly.

What should I check if my metal lathe isn’t working?

Check the power supply, wiring connections, and any visible signs of damage. Make sure everything is plugged in and switched on. These simple steps can often solve the issue quickly.

Best Practices for Metal Lathe Maintenance

Routine maintenance tasks to ensure longevity and performance. Wiring checks as part of a general maintenance schedule.

Keeping your metal lathe in top shape is key to its success. Simple tasks make a big difference. Try these routine maintenance tasks:

- Check oil levels weekly.

- Clean parts to prevent dust buildup.

- Inspect belts and pulleys for wear.

- Ensure all bolts are tight.

Don’t forget about wiring checks too. Look over wires for signs of damage or wear. Keeping everything in good condition helps your lathe last longer and work better.

Why is metal lathe maintenance important?

Regular maintenance keeps your machine running smoothly and prevents costly repairs.

Resources for Further Learning

Recommended books, websites, and forums for metal lathe enthusiasts. Online courses and workshops for enhanced skills.

Many books and websites offer great info for metal lathe fans. Check out titles like “Metalworking for Dummies” for a light read. Forums like Reddit and Machinist’s Network are fun places to ask questions, too. You can also boost your skills by signing up for online courses or workshops. Some even provide hands-on training! Remember, learning is a journey, and it’s way more fun with friends (and metal shavings)!

| Resource Type | Recommended Resources |

|---|---|

| Books | “Metalworking for Dummies” |

| Websites | Machinist’s Network, Reddit |

| Online Courses | Udemy Metalworking Courses |

Conclusion

In summary, a metal lathe helps shape metal into useful parts. Understanding the lathe wiring diagram is important for safe operation. You can create awesome projects by mastering these skills. We encourage you to explore more about lathe techniques and practice safely. Start small and gradually take on bigger challenges. Happy turning!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Wiring Diagrams:

Sure! A lathe is a machine that helps us shape metal by spinning it. We can make things like tools or parts with it. Wiring diagrams show how to connect the parts of the lathe to make it work. They help us understand where every wire goes. Using a lathe is fun, and it lets us create cool projects!

Sure! Please provide the question you want me to answer, and I’ll help you out.

What Are The Essential Components To Include In A Wiring Diagram For A Basic Metal Lathe?

To create a wiring diagram for a basic metal lathe, you need a few important parts. First, include the power source, which gives energy to the lathe. Next, draw the motor, which helps make the lathe turn. Don’t forget to add switches, which you can use to turn the machine on and off. Finally, show the connections using lines to link everything together. This way, we can see how everything works.

How Do You Interpret A Wiring Diagram For A Metal Lathe When Troubleshooting Electrical Issues?

To interpret a wiring diagram for a metal lathe, first, look at the different parts. Each part has lines that show how they connect. You can follow these lines to see where power goes. If something is not working, check the connections or wires on the diagram. This helps you find the problem quickly.

What Safety Precautions Should Be Taken When Working With The Wiring Of A Metal Lathe?

When working with the wiring of a metal lathe, you should always turn off the machine first. Make sure to wear rubber gloves to stay safe from electric shocks. Check that the wires are in good condition and not damaged. Keep your hands dry and avoid touching metal parts while working. If you’re not sure about something, ask an adult for help.

How Does The Wiring Diagram Vary Between A Manual Metal Lathe And A Cnc Metal Lathe?

A manual metal lathe has a simple wiring diagram. It connects basic parts like the motor and controls directly. A CNC metal lathe, which stands for Computer Numerical Control, has more wires and connections. It needs to hook up to a computer that tells it what to do. This makes the CNC lathe more complicated but also much smarter!

Can You Explain The Function Of Each Wire In A Typical Metal Lathe Wiring Diagram?

In a metal lathe wiring diagram, wires have different jobs. One wire gives power to the machine. Another wire connects to the motor, making it spin. Some wires let you control the speed. Finally, there are wires for safety, like turning off the lathe when needed. Each wire works together to help the lathe run safely and smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Metal Shaping And Metal Lathe Wiring Diagrams:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps us shape metal by spinning it. We can make things like tools or parts with it. Wiring diagrams show how to connect the parts of the lathe to make it work. They help us understand where every wire goes. Using a lathe is fun, and it lets us create cool projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer, and I’ll help you out.”}},{“@type”: “Question”,”name”: “What Are The Essential Components To Include In A Wiring Diagram For A Basic Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To create a wiring diagram for a basic metal lathe, you need a few important parts. First, include the power source, which gives energy to the lathe. Next, draw the motor, which helps make the lathe turn. Don’t forget to add switches, which you can use to turn the machine on and off. Finally, show the connections using lines to link everything together. This way, we can see how everything works.”}},{“@type”: “Question”,”name”: “How Do You Interpret A Wiring Diagram For A Metal Lathe When Troubleshooting Electrical Issues?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To interpret a wiring diagram for a metal lathe, first, look at the different parts. Each part has lines that show how they connect. You can follow these lines to see where power goes. If something is not working, check the connections or wires on the diagram. This helps you find the problem quickly.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Working With The Wiring Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working with the wiring of a metal lathe, you should always turn off the machine first. Make sure to wear rubber gloves to stay safe from electric shocks. Check that the wires are in good condition and not damaged. Keep your hands dry and avoid touching metal parts while working. If you’re not sure about something, ask an adult for help.”}},{“@type”: “Question”,”name”: “How Does The Wiring Diagram Vary Between A Manual Metal Lathe And A Cnc Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A manual metal lathe has a simple wiring diagram. It connects basic parts like the motor and controls directly. A CNC metal lathe, which stands for Computer Numerical Control, has more wires and connections. It needs to hook up to a computer that tells it what to do. This makes the CNC lathe more complicated but also much smarter!”}},{“@type”: “Question”,”name”: “Can You Explain The Function Of Each Wire In A Typical Metal Lathe Wiring Diagram?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In a metal lathe wiring diagram, wires have different jobs. One wire gives power to the machine. Another wire connects to the motor, making it spin. Some wires let you control the speed. Finally, there are wires for safety, like turning off the lathe when needed. Each wire works together to help the lathe run safely and smoothly.”}}]}