Have you ever felt frustrated when your lathe motor starts to slow down? It can be annoying, especially when you’re in the middle of an important project. Don’t worry; you’re not alone! Many hobbyists and professionals face this issue. But what if I told you that replacing the lathe motor could transform your metal lathe into a powerful CNC machine?

Imagine effortlessly cutting through metal with precision. A lathe motor replacement can make this dream come true. Upgrading to a better motor will help your machine work faster and smoother. This can lead to better results in your projects.

Have you thought about retrofitting your metal lathe? This process involves adding modern parts to make it better. Just like tuning up a car, you can improve performance. By replacing your lathe motor and adding new technology, you can unlock your machine’s full potential.

Join us as we explore the world of lathe motor replacements and CNC retrofits. Discover steps and tips to easily upgrade your lathe. Let’s dive in and make your metal lathe work like new!

Lathe Motor Replacement For Metal Lathe Cnc Retrofit Solutions

Lathe Motor Replacement for CNC Retrofit

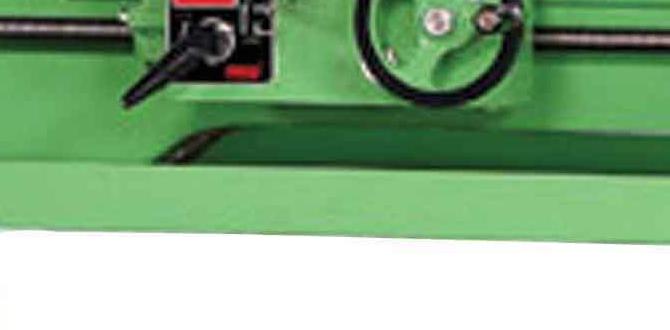

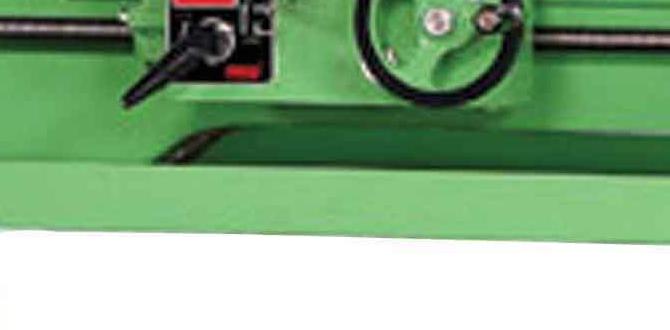

Looking to upgrade your metal lathe? A lathe motor replacement is key for a successful CNC retrofit. This upgrade can boost efficiency and performance. Imagine transforming your older machine into a modern powerhouse! Choosing the right motor ensures smooth operations and better control. Did you know that with the right setup, you can achieve precise cuts easily? Upgrading not only improves speed but also extends the lathe’s lifespan. Embrace innovation to enhance your metalworking projects today!Understanding Lathe Motors

Types of lathe motors used in metal lathes. Importance of motor specifications in CNC retrofitting.Lathe motors come in a few types, each with its own charm. You have the DC motor, perfect for smooth speeds, and the mighty AC motor, which loves to go fast! The specifications of these motors matter a lot, especially with CNC retrofitting. Picking the right motor means smoother operations and happier projects. Think of it like picking the right shoe for running; you don’t want to stumble on your way to greatness!

| Motor Type | Key Features |

|---|---|

| DC Motor | Smooth speed control, ideal for intricate tasks |

| AC Motor | High speed, great for heavier jobs |

Getting the right specs ensures your retrofitting works. It’s like ensuring your toolbox is packed with the right tools—no one wants to use a spoon to tighten a bolt!

Signs You Need to Replace Your Lathe Motor

Common issues indicating motor failure. Performance drops and vibration detection.Noticing problems with your lathe motor can save you time and money. Here are some common signs it may need replacing:

- Unusual noises during operation can signal trouble.

- Performance drops mean it isn’t working as well.

- Vibration detection may indicate issues inside the motor.

If you see these signs, it’s time to check your motor closely. Waiting can lead to bigger problems in the future.

What are the signs of lathe motor failure?

Signs include unusual noises, drops in performance, and increased vibration.

Selecting the Right Replacement Motor

Key specifications to consider (power, RPM, torque). Compatibility with existing CNC systems.Choosing a replacement motor for your lathe is important. You need to check a few key specifications. First, look at the power. It tells you how hard the motor can work. Next is the RPM or revolutions per minute. Higher RPM means faster speeds. Lastly, consider torque, which shows the motor’s strength. It helps cut through tough materials. Also, make sure the motor fits well with your existing CNC system. Compatibility guarantees smooth performance.

What specifications should I look for in a lathe motor?

Key specifications for a lathe motor include:

- Power: Measure in watts or horsepower for work efficiency.

- RPM: Higher is better for speed.

- Torque: Essential for cutting strength.

Preparing for the Replacement Process

Tools and equipment needed for replacement. Safety precautions and best practices.Before starting the replacement, gather the right tools. You will need a wrench, screwdriver, and safety goggles. Don’t forget gloves for hand protection. Safety is key. Always ensure the machine is unplugged. Here are some tips to follow:

- Wear safety glasses to protect your eyes.

- Keep your workspace tidy to avoid accidents.

- Have a friend help you for safety.

By being prepared and safe, the process will go smoothly.

What tools do I need to replace a lathe motor?

You need basic tools like a wrench, screwdriver, and safety gear. These make the job easier and safer.

Step-by-Step Guide to Replacing the Lathe Motor

Detailed instructions for removing the old motor. Instructions for installing the new motor correctly.First, ensure your lathe is unplugged. Safety first, right? Next, remove the screws holding the old motor. You may need a little wiggling—think of your motor as a stubborn cat! Carefully lift the motor out. Don’t drop it; it won’t bounce like a rubber ball.

Now, let’s install the new motor. Place it in the same spot as the old one and secure it with screws. Check that all connections are tight. A loose wire? Not from this workshop! Finally, plug it in and give it a test run. If it purrs like a kitten, you’re good to go!

| Step | Description |

|---|---|

| 1 | Unplug the lathe. |

| 2 | Remove screws from the old motor. |

| 3 | Lift out the old motor carefully. |

| 4 | Install the new motor and secure it. |

| 5 | Test the motor by plugging it in. |

Testing the New Motor Setup

How to run initial tests after installation. Troubleshooting common issues before regular use.After you install your shiny new motor, it’s time for a test run! Start by connecting the power and switching it on. Listen for any strange sounds—if it sounds like a cat trying to sing, you might have a problem! Test the speed and torque levels too. If it’s moving slower than a snail, check the connections. Below is a handy table with common issues and quick fixes:

| Issue | Quick Fix |

|---|---|

| No Power | Check power supply and connections |

| Motor Overheating | Ensure proper ventilation |

| Weird Noises | Inspect for loose parts |

Don’t be shy—give it some test cuts! If everything is running smooth, it’s time to get to work. If problems arise, remember: troubleshooting is just part of the fun! Happy lathe-ing!

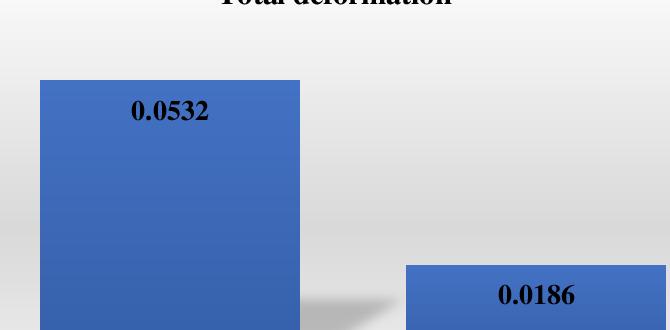

Benefits of Upgrading to a New Lathe Motor

Improved efficiency and performance capabilities. Longterm cost savings and reduced maintenance.Upgrading to a new lathe motor brings many great benefits. First, it boosts efficiency and performance. This means you can work faster and create better products. Second, it leads to long-term cost savings. A newer motor can use less energy and require fewer repairs. Overall, these changes help you save both time and money in the long run.

Why is upgrading important?

Upgrading is important because it helps your lathe perform better. New motors often come with better technology. This helps turn projects into finished products quickly and efficiently.

Key Benefits:

- Improved Efficiency: Work faster with less effort.

- Lower Costs: Save money on energy and repairs.

DIY vs. Professional Replacement Services

Pros and cons of replacing the motor yourself. When to consider hiring a professional service.Replacing your lathe motor can be a fun puzzle, but it has its ups and downs. On the bright side, doing it yourself can save money and help you learn new skills. You’ll feel like a superhero when you fix it! However, if you’re not sure what to do, it could turn into quite the mystery.

Sometimes, hiring a pro is best, especially if you want things done right without any “oops” moments. If the job feels more like a jig-saw puzzle of doom than a fun project, it might be time to call for backup. Weigh your options carefully—after all, you don’t want that motor running away from you!

| DIY Replacement | Professional Service |

|---|---|

| Cost-effective | Time-saving |

| Skill-building | Expert quality |

| Risk of mistakes | Higher cost |

Think carefully about your choice. Whether you go DIY or hire a pro, keep your lathe running smoothly and your spirit high!

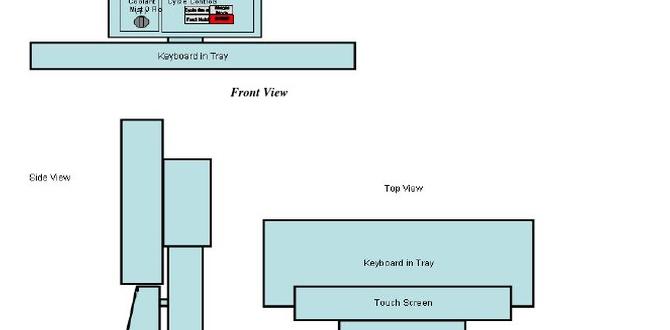

CNC Retrofit Considerations

Integrating the new motor with existing CNC components. Software updates and configurations needed.Swapping in a new motor for your CNC machine can feel like a puzzle. First, you need to check how the new motor fits with your current CNC parts. It’s a bit like making sure that your new shoes match your favorite outfit! Next, you’ll need to update the software. This might sound tricky, but software updates are as necessary as doing your homework before a big test. They ensure your machine runs smoothly and safely.

| Consideration | Details |

|---|---|

| Motor Integration | Ensure compatibility with existing components. |

| Software Update | Update settings to match the new motor specs. |

Make sure to double-check that everything matches perfectly. Remember, like a cat trying to fit into a tiny box, you want your motor to fit seamlessly! With these steps, you’ll be on the fast track to a powerful lathe experience!

Maintenance Tips for Longevity of Your New Motor

Regular checkups and preventive maintenance practices. Understanding motor wear and when to replace components again.To keep your new motor running smoothly, regular checkups are key. Check for unusual noises or vibrations. These could mean something isn’t right. It’s important to understand motor wear. If you notice wear on parts, it might be time for replacements. Take action before problems get worse!

- Inspect connections and wires.

- Check for dirt or debris. Clean if needed.

- Lubricate as suggested in the manual.

Following these tips can help your motor last longer.

How often should you check your motor?

Check your motor’s health at least every month. This helps catch any issues early.

Conclusion

In conclusion, replacing your lathe motor can greatly improve your metal lathe’s performance. It’s a smart upgrade for CNC retrofits. We learned that choosing the right motor boosts efficiency and precision. If you want to learn more, check out guides or videos online. Taking these steps will help you get the best results from your lathe project!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Motor Replacement And Cnc Retrofit For Metal Lathes:If you want to replace a lathe motor, you first need to check the old motor’s size and power. After that, you can buy a new motor that fits well. If you’re thinking about a CNC retrofit, that means adding computer controls to your lathe. This makes cutting metal easier and more accurate. You’ll need to follow some steps to set it up correctly.

Sure! Please ask your question, and I’ll be happy to help.

What Are The Key Factors To Consider When Selecting A Replacement Motor For A Metal Lathe During A Cnc Retrofit?When you choose a new motor for a metal lathe, think about a few important things. First, check the motor’s power. It needs to be strong enough for your work. Next, consider the size of the motor. It should fit well in your lathe. Also, think about how fast the motor can go. Faster speeds help you work quicker. Finally, make sure the motor is easy to connect to your CNC (Computer Numerical Control) system.

How Does The Power Rating Of A New Motor Impact The Performance And Capabilities Of A Retrofitted Cnc Lathe?A motor’s power rating tells us how strong it is. When you put a stronger motor in a CNC lathe, it can work faster and cut harder materials. This means you can make better parts in less time. However, we need to make sure the lathe can handle the new motor so everything works well together. A good motor helps your machine do more cool things!

What Tools And Skills Are Necessary For Replacing The Motor In A Metal Lathe And Installing A Cnc Control System?To replace the motor in a metal lathe, you will need a few tools. You should have wrenches, screwdrivers, and maybe pliers. For skills, you need to know how to follow instructions and work carefully. To install a CNC control system, you’ll also need a computer and some basic wiring tools. It helps if you can read diagrams and understand simple electronics.

Are There Specific Motor Types (E.G., Stepper, Servo, Or Brushless Dc) That Are Better Suited For Cnc Retrofitting Of Lathes?Yes, some motors are better for CNC retrofitting of lathes. Stepper motors are good for simple tasks because they are easy to control. Servo motors are great for precise movements and speed. Brushless DC motors are fast and efficient too. Choosing the right motor depends on what you need for your lathe.

What Common Challenges Might Arise During The Lathe Motor Replacement And Cnc Retrofit Process, And How Can They Be Addressed?When we replace the lathe motor and upgrade to a CNC (Computer Numerical Control) system, we might face a few problems. First, fitting the new motor can be tricky because it needs to match perfectly with other parts. We can solve this by measuring carefully and asking for help if we’re unsure. Second, we might need to connect new wires, which can be confusing. It’s important to follow instructions step-by-step and check connections to prevent mistakes. Lastly, programming the CNC can be tough, but watching videos or getting expert help can make it easier.