Have you ever watched a metal lathe spinning smoothly? It’s fascinating to see it shape metal with precision. But what happens when something goes wrong?

Many metal lathe owners face a common problem: the lathe motor needs replacement. This issue can be frustrating for anyone who loves crafting with metal. Imagine you’re in the middle of an exciting project, and suddenly, your machine stops working!

That’s where the lathe motor replacement comes into play. Learning how to replace a motor can save you time and money. Plus, understanding your metal lathe control panel makes everything easier.

Did you know that a well-functioning lathe motor can improve your projects? It can boost your creativity and help you finish tasks faster. In this article, we will explore the steps to replace your lathe motor and how to use the control panel effectively. Let’s dive in and get your lathe up and running again!

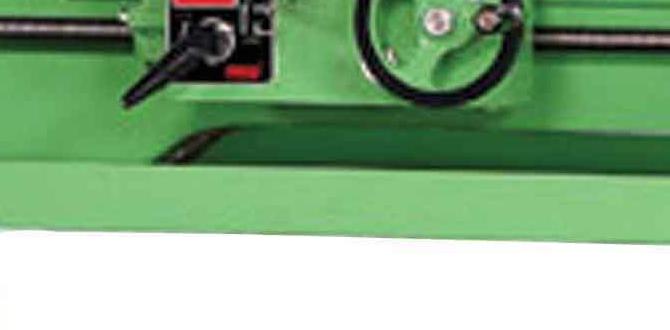

Lathe Motor Replacement: Metal Lathe Control Panel Guide

Lathe Motor Replacement Metal Lathe Control Panel

Replacing a lathe motor can seem tricky, but it’s important for smooth operation. First, understand the lathe’s control panel. This part manages speed and direction, making it vital to your project. When replacing a motor, ensure compatibility with your control panel. Did you know a good motor can extend your lathe’s life? By following simple steps, you can upgrade and improve precision. Always take safety precautions. It’s all about keeping your tools in top shape!

Understanding Lathe Motors

Types of lathe motors and their functions. Importance of selecting the right motor for your metal lathe.

Lathe motors are essential for your metal lathe to work well. There are two main types: AC motors and DC motors. AC motors are great for steady operation, while DC motors offer better speed control. Choosing the right motor helps your lathe perform at its best. This choice can save time and make your projects smoother. After all, nobody wants their lathe to throw a tantrum mid-project, right? Let’s break it down with a simple table:

| Motor Type | Function |

|---|---|

| AC Motor | Provides steady power |

| DC Motor | Offers precise speed control |

Signs You Need a Motor Replacement

Common symptoms of motor failure in metal lathes. Diagnostic checks to confirm motor issues.

Have you noticed strange sounds or a sudden drop in speed while using your metal lathe? These are often clear signs that your motor may be failing. Other symptoms can include the lathe stalling unexpectedly or giving off unusual smells. To confirm if your motor needs replacing, check for loose wires and overheating. Watching for these signs early can save you from a bigger headache later!

| Symptoms | Diagnostic Checks |

|---|---|

| Weird noises | Inspect wiring connections |

| Unexpected stalls | Check for overheating |

| Loss of speed | Measure voltage supply |

| Unpleasant odors | Listen for unusual vibrations |

Choosing the Right Replacement Motor

Key specifications to consider (horsepower, RPM, voltage). Compatibility with existing metal lathe models.

Finding the perfect motor for your lathe is like choosing the right ice cream flavor—there are so many options! First, check the horsepower, which gives you the power to spin, drill, and cut like a pro. Next, consider RPM (revolutions per minute); this tells you how fast the motor can run. Take note of the voltage too, as it ensures compatibility with your setup.

Remember that not all motors fit every lathe. So, make sure your new motor works with your existing model. It’s like making sure your favorite toppings fit on the pizza! Here’s a quick table of key specs to help you out:

| Specification | Details |

|---|---|

| Horsepower | Choose based on work type |

| RPM | Higher for faster tasks |

| Voltage | Match with your current setup |

Step-by-Step Guide to Replacing Your Lathe Motor

Tools and materials needed for replacement. Detailed procedure for safe and effective motor replacement.

Before starting your lathe motor replacement, gather these tools and materials:

- Screwdrivers (flat and Phillips)

- Wrenches

- Replacement lathe motor

- Wiring connectors

- Safety gloves and goggles

Ensure safety by unplugging the machine. Remove the old motor by unscrewing it carefully. Disconnect wires while taking notes for reattachment. Position the new motor and secure it tightly. Finally, connect the wires as marked. Double-check everything before plugging in.

What tools do you need for motor replacement?

You will need screwdrivers, wrenches, and a replacement lathe motor.

Wiring and Electrical Considerations

Important wiring guidelines for lathe motor and control panel integration. Safety precautions to take during installation.

Wiring a lathe motor with a control panel needs care. Follow these important guidelines:

- Always switch off the power before starting.

- Use correct gauge wires for the motor’s requirements.

- Connect color-coded wires to avoid mistakes.

- Secure connections with electrical tape or heat shrink tubing.

Also, don’t forget to take safety precautions:

- Wear gloves and goggles.

- Keep tools dry to avoid electrical shock.

- Double-check your work before powering on the machine.

These steps will help you safely install your lathe motor and control panel.

What safety precautions should I take during installation?

Always disconnect power, wear protective gear, and check connections carefully. These actions help prevent accidents and ensure a smooth running machine.

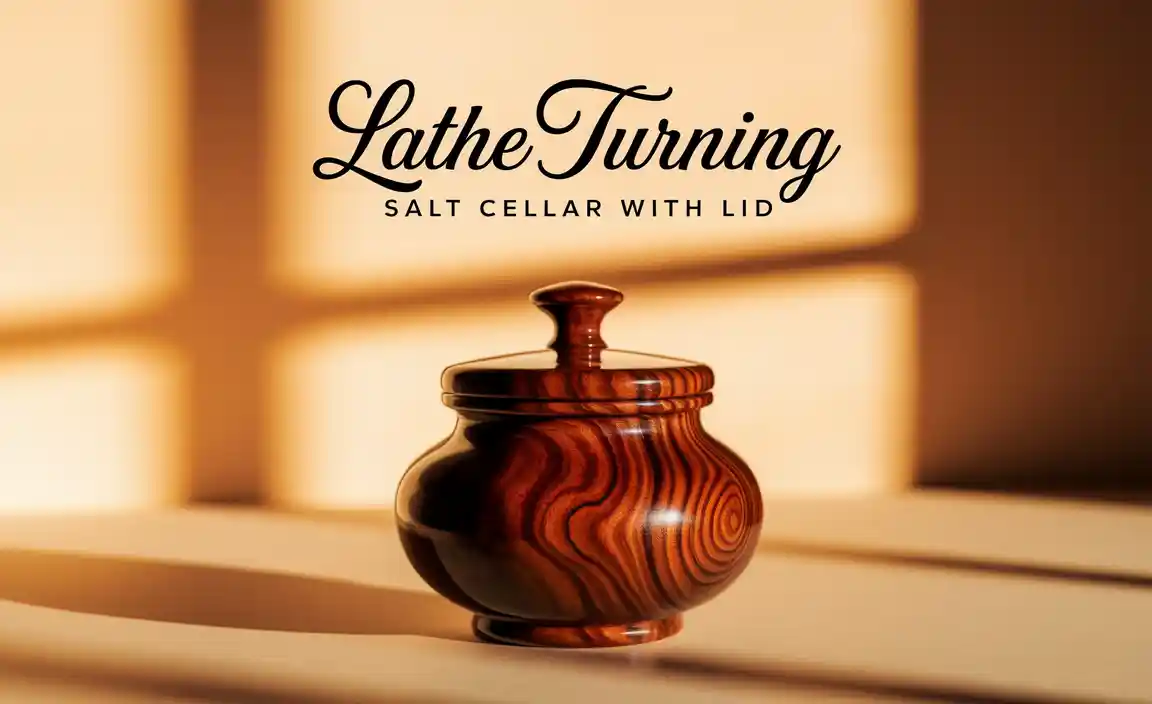

Testing Your New Motor and Control Panel Setup

Procedures for testing functionality postinstallation. Troubleshooting common issues after replacement.

Testing your lathe motor and control panel is vital for safe operation. Start by turning on the power and checking for any unusual noises. Use this simple procedure:

- Ensure all connections are secure.

- Run the lathe at low speed first.

- Observe the movement and listen closely for issues.

- Gradually increase the speed to test limits.

If problems arise, troubleshoots common issues:

- Check for loose wires.

- Inspect fuses or circuit breakers.

- Review the control panel settings.

Remember, a well-installed system can last for years with proper care!

What are common problems after replacing a lathe motor?

Common issues include no power, strange noises, or inconsistent speeds. Check connections and settings if you face these problems!

Maintenance Tips for Longevity of Lathe Motors

Regular maintenance practices to extend motor lifespan. Signs of wear that should be regularly inspected.

Taking care of your lathe motor can help it last longer. Regular checks can spot issues before they become big problems. Here are some good practices:

- Keep the motor clean and free from dust.

- Check the wiring for cuts or frays.

- Listen for strange noises while it runs.

- Look for vibrations that hint at loose parts.

- Monitor the temperature for overheating.

Pay attention to these signs. Your lathe motor will thank you for it!

What are common signs of wear in lathe motors?

Common signs include strange noises, unusual vibrations, and overheating. If you notice these, check your motor right away!

FAQs About Lathe Motor Replacement

Commonly asked questions regarding motor replacement and control panel usage. Expert tips for ensuring a successful installation.

Replacing the lathe motor can sound tricky, but don’t fret! Common questions include: “How do I choose the right motor?” and “What steps should I follow for the best results?” An expert tip is to always check compatibility with your control panel. Ensure you’ve turned off all power before starting—safety first! After you swap out the motor, double-check the connections. And if you run into trouble, remember: “It’s just a machine, not a unicorn!”

| Question | Answer |

|---|---|

| What tools do I need? | A basic toolbox with wrenches and screwdrivers will do! |

| Is it hard to install? | Not really, just follow instructions closely! |

Conclusion

In conclusion, replacing the lathe motor or fixing the control panel can boost your metal lathe’s performance. We learned that regular maintenance keeps machines running smoothly. You should explore manuals and tutorials for guidance. If you’re unsure, consider asking an expert. Remember, a well-maintained lathe makes working with metal much easier and more enjoyable!

FAQs

What Are The Key Factors To Consider When Selecting A Replacement Motor For A Metal Lathe?

When picking a new motor for your metal lathe, you should check a few important things. First, look at the motor’s power. You want it to match or be stronger than the old one. Next, think about the size and fit. It should fit in the same space without any issues. Lastly, check the type of power it needs, like electricity or battery, to make sure it works with your setup.

How Do I Determine The Appropriate Horsepower And Rpm Specifications For My Lathe Motor Replacement?

To find the right horsepower and RPM for your lathe motor, first check the old motor’s label. It will show the horsepower and RPM numbers. If you can’t find it, ask someone who knows about lathes. You want the new motor to match these numbers so it works properly. Also, think about the type of work you’ll do; that might need a bit more power.

What Are The Common Signs That Indicate The Need For Replacing The Motor On A Metal Lathe?

If your metal lathe’s motor makes strange noises, it can be a sign it’s failing. You might notice it runs slowly or stops working suddenly. Sometimes, the motor may get very hot or smell bad. If these things happen, you may need to replace the motor to keep using the lathe safely.

How Can I Troubleshoot Issues With The Control Panel Related To A Malfunctioning Lathe Motor?

First, check if the control panel is getting power. Make sure it’s plugged in and the switch is on. Next, look for any loose wires connected to the motor. If everything looks good, try resetting the panel by turning it off and on. If it still doesn’t work, ask a grown-up for help.

What Steps Should I Follow To Safely Install A New Motor And Control Panel On My Metal Lathe?

First, make sure the lathe is turned off and unplugged. Then, carefully remove the old motor and control panel. Next, follow the instructions that come with the new motor and control panel. Connect the wires as shown in the instructions. Finally, check everything to ensure it’s tight and safe, then plug it back in and test it. Always wear safety gear!