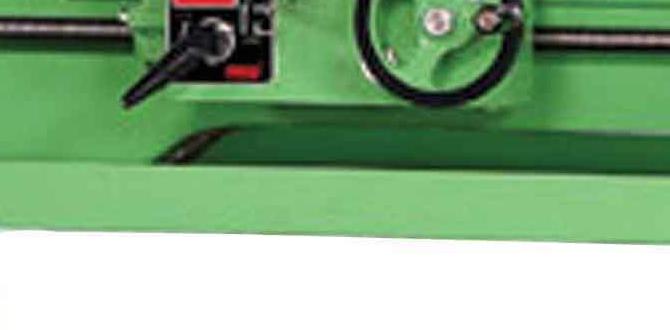

Have you ever wondered how machines like lathes work? These fascinating tools shape and cut metal with precision. A big part of this magic comes from the lathe motor. But what happens when that motor breaks down? Do you have to buy a whole new lathe?

Don’t worry! You can often replace just the motor. This process is simpler than you might think. When you change the lathe motor, you can breathe new life into your metal lathe drive system. Imagine keeping your favorite tool alive and working like new.

In this article, we will explore how to replace the lathe motor. We’ll share useful tips and tricks to make it easy. Get ready to learn how to take control of your metal lathe and keep it running smoothly!

Lathe Motor Replacement For Metal Lathe Drive System

Lathe Motor Replacement: Understanding Metal Lathe Drive Systems

Replacing the lathe motor can boost your metal lathe’s performance. A good drive system ensures smooth operation, and choosing the right motor is key. Did you know a stronger motor can cut through tougher materials? By upgrading, you can also improve precision in your work. Whether it’s for hobby projects or professional tasks, knowing how to replace the motor easily saves time and enhances your skills. Dive in to discover tips for a seamless swap!

Understanding Lathe Motors

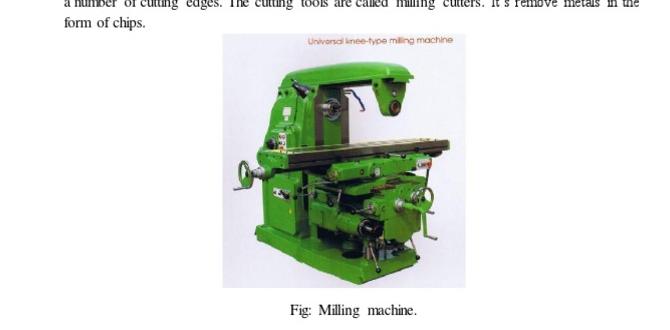

Explanation of how lathe motors function in a drive system. Types of lathe motors commonly used in metal lathes.

Lathe motors are the heart of a metal lathe’s drive system, spinning the machine like a top. They turn electrical energy into motion, allowing you to shape metal with ease. There are a few common types of lathe motors used in these machines. The most popular ones are AC motors and DC motors. AC motors provide steady power, while DC motors offer better speed control. Understanding these options will help you pick the right replacement motor when your old one decides to retire.

| Type of Motor | Description |

|---|---|

| AC Motor | Powers the lathe with constant torque |

| DC Motor | Provides adjustable speed for precision |

Signs Your Lathe Motor Needs Replacement

Common symptoms indicating motor failure. Impacts of a malfunctioning motor on lathe performance.

Ever notice a strange sound coming from your lathe? Is it vibrating like it wants to dance? These are signs your lathe motor might be waving a white flag. Common symptoms of motor failure include inconsistent speed and a decrease in power. A malfunctioning motor can seriously affect performance, making cuts uneven and frustrating. If you often find yourself talking sweetly to your lathe, it might be time for a check-up!

| Symptoms | Impact on Performance |

|---|---|

| Strange noises | Uneven cuts |

| Inconsistent speed | Reduced accuracy |

| Vibrations | Increased wear |

Choosing the Right Replacement Motor

Factors to consider when selecting a replacement motor. Comparison of motor types: AC vs. DC options.

Finding the right motor to replace your lathe can feel like picking the best pizza topping. You want something that works smoothly and fits well! First, consider power needs. Different tasks need different muscle. Next up is the motor type: AC motors are great for constant speeds, while DC motors offer adjustable speeds like a fancy blender’s settings. This can make your projects go from zero to awesome!

| Motor Type | Pros | Cons |

|---|---|---|

| AC Motor | Steady & reliable | Less adjustable |

| DC Motor | Speed control! | Can wear out faster |

Choose wisely, and your lathe will be as happy as a cat in a sunbeam!

Step-by-Step Guide to Replacing Your Lathe Motor

Tools and materials needed for replacement. Detailed process for safely removing and installing a new motor.

Replacing a lathe motor can seem tricky, but with the right tools, you’re halfway there! Gather your stunning arsenal: a wrench, screwdriver, safety goggles, and a new motor that matches your old one. Don’t forget to wear your superhero cape—safety first!

| Tools | Materials |

|---|---|

| Wrench | New Lathe Motor |

| Screwdriver | Mounting Hardware |

| Safety Goggles | Electrical Connectors |

To kick off the process, unplug your lathe to avoid unexpected dance moves! Next, remove the old motor by unscrewing it, like taking off a stubborn lid. Finally, install the new motor by reversing the steps. Secure it tight, check connections, and voilà! You’re ready to make some wobbly yet fabulous creations!

Maintenance Tips for Longevity of Your Lathe Motor

Routine maintenance practices to prevent motor failure. Troubleshooting common issues with lathe motors.

To keep your lathe motor running well, regular care is essential. Here are some simple tips:

- Check the electrical connections often. Loose wires can cause problems.

- Clean the motor regularly to prevent dust build-up.

- Lubricate moving parts to ensure smooth operation.

- Watch for strange sounds. They might signal trouble.

- Inspect for overheating. If it feels hot, stop using it right away.

Troubleshooting is easy with a few basic checks. If it doesn’t turn on, check the power supply and plug. If it vibrates too much, the mounting might be loose. Address these quickly to avoid more damage.

How can you troubleshoot common lathe motor issues?

To handle lathe motor issues, always start with the basic checks. Look for loose wires or burned-out fuses. If it runs poorly, check for blocked air vents or dirt buildup. Keeping an eye on these things ensures your lathe works great!

Cost Considerations for Lathe Motor Replacement

Breakdown of potential costs involved in replacement. Tips for finding budgetfriendly motor options without compromising quality.

Replacing a lathe motor can feel like a trip to the dentist—unpleasant and often a bit costly. First, budget for the new motor, which can vary greatly, ranging from $100 to $600 or more, depending on quality and brand. Don’t forget shipping! Next, include the cost of tools and any extra parts you might need. To save some coins, look for discounted motors online. Websites can be treasure troves! Also, check local suppliers—they sometimes offer better deals. Remember, cheap isn’t always the best choice; you want your lathe to purr, not wheeze like an old bicycle!

| Cost Item | Estimated Range |

|---|---|

| Motor | $100 – $600+ |

| Shipping | $20 – $50 |

| Tools & Parts | $30 – $150 |

Case Studies: Successful Lathe Motor Replacements

Examples of notable lathe motor replacement projects. Lessons learned and best practices from each case study.

Many people have successfully replaced lathe motors, learning valuable lessons along the way. One project involved changing an old motor with a modern one for better efficiency. This led to smoother operation and energy savings. Another case showcased a DIY enthusiast who upgraded the system, resulting in improved speed and performance.

- Always check motor compatibility before starting.

- Focus on quality parts for lasting results.

- Document each step to make future replacements easier.

Success in these projects shows that proper planning pays off. Every upgrade not only improved the lathe’s function but also taught users how to handle similar tasks confidently.

What are the key benefits of lathe motor replacement?

Key benefits include better performance, energy efficiency, and reduced maintenance costs.

Conclusion

In summary, replacing your lathe motor is essential for a smooth metal lathe drive system. It boosts performance and extends your lathe’s life. Remember to choose the right motor for your needs. You can find helpful guides online or ask for advice at your local hardware store. Start your research today to improve your metalworking skills!

FAQs

What Are The Signs That Indicate It’S Time To Replace The Motor In A Metal Lathe Drive System?

You should think about replacing the motor in a metal lathe if it makes strange noises or smells like burning. If the motor shakes a lot or has trouble starting, that’s a bad sign too. You can also check if it gets too hot when you use it. If the lathe often stops working or runs very slowly, it might be time for a new motor.

What Types Of Motors Are Suitable For Replacement In A Metal Lathe, And How Do They Differ In Performance?

You can replace a metal lathe motor with a few types. The most common options are AC (alternating current) motors and DC (direct current) motors. AC motors are good for steady power and can run for a long time. DC motors are better for speed control and quick changes, but they may not run as long without stopping. Each motor type has its own strengths, so you should pick the best one for your needs.

How Do You Determine The Correct Horsepower And Torque Specifications For A Replacement Lathe Motor?

To find the right horsepower and torque for a lathe motor, you start with the old motor’s specs. You can look for a label or manual that shows this information. Next, think about what you will use the lathe for. If you’re doing heavier work, you need more horsepower and torque. Finally, check with the lathe’s manufacturer or a friendly expert if you’re unsure.

What Tools And Steps Are Required To Safely Remove The Old Motor And Install The New One In A Metal Lathe?

To safely remove the old motor from the metal lathe, you need a few tools. Get a socket wrench, screwdrivers, and pliers. First, unplug the lathe to keep it safe. Then, use the wrench to take off the screws holding the motor. Next, carefully lift out the old motor and place in the new one. Finally, screw it back in place and reconnect everything. Make sure to test it before using!

How Can Upgrading The Motor In A Metal Lathe Improve Overall Machining Efficiency And Precision?

Upgrading the motor in a metal lathe makes it stronger and faster. This means you can work quicker and make better cuts. A better motor helps the lathe run smoothly, so you get less vibration. When your tools are more stable, they create more accurate shapes. Overall, this leads to better work and less time wasted!