Have you ever wondered how a metal lathe works? It spins and shapes metal pieces into amazing tools and parts. But what happens when the lathe motor needs a replacement? Many people think it’s a daunting task. However, replacing the lathe motor or the metal lathe pulley can be straightforward if done correctly.

Imagine you’re in your workshop, trying to fix something important. Suddenly, the lathe motor stops working. Frustrating, right? But don’t worry! Understanding how to replace the motor and pulley can save the day. It can also save you money!

Fun fact: A lathe has been around for thousands of years. Its design has changed, but its purpose remains the same. Keeping your lathe running smoothly is essential for your projects. So, let’s explore the steps you need to take for a successful lathe motor replacement and how to handle that pesky metal lathe pulley.

Lathe Motor Replacement: Upgrading Your Metal Lathe Pulley

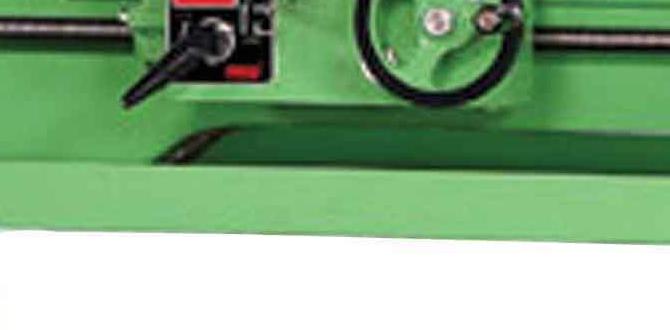

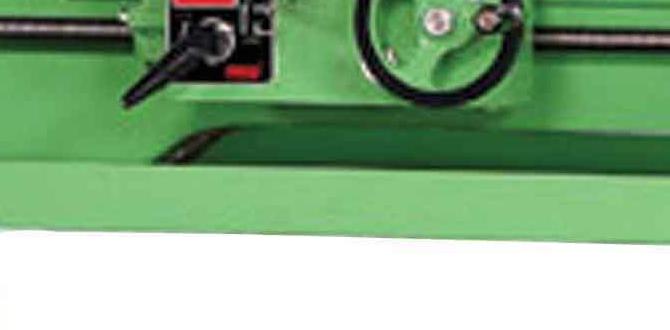

Lathe Motor Replacement Metal Lathe Pulley

Replacing a lathe motor pulley is crucial for maintaining machine performance. Over time, wear and tear can affect your lathe’s effectiveness. Have you ever noticed strange sounds while operating? It might be time for a replacement. A new pulley ensures proper tension and smooth operation, boosting productivity. Choosing the right size and type is essential. Did you know that even a small change can enhance your lathe’s efficiency? Keep your projects running smoothly with proper maintenance.

Signs That Your Lathe Motor Needs Replacement

Common symptoms of a failing lathe motor. How to diagnose motor issues effectively.

Is your lathe motor acting up? Here are some common signs it might need replacement:

- Strange noises while operating

- Slower than normal speeds

- Frequent overheating

- Vibration or wobbling during use

To diagnose these issues, check the power supply and look for loose connections. Remember, a faulty motor can lead to bigger problems down the line. Always address symptoms early!

How can you tell if a lathe motor is failing?

Listen for unusual sounds or check for overheating. These are early indicators of trouble. Don’t ignore them!

Selecting the Right Replacement Motor

Factors to consider when choosing a lathe motor. Recommended specifications for metal lathe motors.

Selecting the right motor is crucial for your lathe. Consider the power you need. Motors come in different strengths. You want one that fits your projects. Look for these key specs:

- Power Rating: Choose a motor with at least 1 HP for good performance.

- Voltage: Make sure it matches your power supply.

- Speed: Select a motor with adjustable speeds for different tasks.

Understanding these factors will help you make a smart choice!

What should I consider when picking a motor?

You should check power, voltage, and speed needs. Each machine has its unique requirements. Pay attention to the size and fit too!

Replacing the Lathe Motor: Step-by-Step Guide

Tools and materials needed for motor replacement. Detailed instructions for safely replacing the lathe motor.

Before starting the lathe motor replacement, gather the right tools. You’ll need a screwdriver, pliers, a wrench, and safety glasses. Make sure to have a new motor and clamps ready. Follow these steps for a safe replacement:

- Unplug the lathe to ensure safety.

- Remove the old motor using the screwdriver.

- Install the new motor carefully.

- Reconnect all wires and check for tightness.

- Plug in the lathe and test the motor.

Always remember safety first! Wear gloves and goggles. This careful approach makes the replacement easy and fun!

What tools do I need to replace a lathe motor?

You will need a screwdriver, pliers, a wrench, safety glasses, and the new motor.

Adjusting the Pulley System After Motor Replacement

Importance of proper pulley alignment for optimal performance. Stepbystep process for adjusting and testing the pulley system.

After changing a motor, it’s vital to adjust the pulley system properly. This ensures everything runs smoothly. Proper alignment helps with optimal performance. Misaligned pulleys can cause wear and tear. Follow these steps:

- Check the alignment of the pulleys.

- Loosen the bolts slightly.

- Adjust the position of the pulleys.

- Tighten the bolts securely.

- Test the system by turning it on.

If there are vibrations, readjust until it’s quiet. This process keeps your lathe running well. Remember, a small change can make a big difference!

Why is adjusting the pulley important?

Proper pulley alignment helps protect your machine and extends its life. It also ensures smooth operation, reducing energy waste and noise.

Common Mistakes to Avoid During Motor Replacement

Typical errors that can occur during replacement. Tips for ensuring a successful lathe motor replacement.

Replacing the motor on your lathe can feel like solving a Rubik’s Cube blindfolded. Common mistakes often arise when folks forget to disconnect power first—yikes! It’s also easy to mix up the pulley sizes. Measure twice, cut once, right? Always keep track of screws and parts; nobody wants a mysterious extra bolt. Here’s a quick tip: refer to a manual or a YouTube video. It’ll save you time and maybe even keep your hair intact!

| Common Mistakes | Tips for Success |

|---|---|

| Forgetting to disconnect power | Always turn off the power before starting |

| Mixing up pulley sizes | Double-check measurements |

| Losing screws and parts | Organize all parts into labeled bags |

| Ignoring instructions | Follow the manual or watch a tutorial |

Maintenance Tips for Longevity of Lathe Motors and Pulleys

Best practices for maintaining your lathe motor. Tips for maintaining pulley systems to prevent future issues.

Taking care of your lathe motor and pulleys is important for long-lasting performance. Here are some tips to keep them running well:

- Check for dirt and debris regularly. Clean the motor and pulleys often.

- Keep the belt tight and replace it if it looks worn.

- Lubricate moving parts according to the manual.

- Avoid overloading the lathe to prevent strain.

- Inspect wiring and connections for damage.

These simple steps can help you avoid problems in the future and ensure smooth operation.

What are key maintenance tips for lathe motors?

Regular cleaning, lubrication, and inspection are crucial for lathe motor care.

How can I maintain the pulley system?

- Keep pulleys aligned and tight to prevent slips.

- Inspect and replace worn-out parts promptly.

Conclusion

In summary, replacing the lathe motor and pulley can greatly improve your metal lathe’s performance. A better motor boosts power, while a new pulley ensures smooth operation. If you’re facing issues, don’t hesitate to consider these upgrades. Remember to check the compatibility before buying. For more tips, keep exploring our articles or ask someone with experience!

FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Motor Replacement And Metal Lathe Pulleys:

Sure! When you need to replace a lathe motor, you should first turn off the power. Then, you can take the old motor out and put the new one in its place. Make sure the new motor is the same size and type as the old one. For pulleys, check if they fit the motor and the lathe. It’s important to tighten everything properly so it works well.

Sure! Please provide me with the question you would like me to answer.

What Factors Should Be Considered When Selecting A Replacement Motor For A Metal Lathe?

When choosing a new motor for a metal lathe, you should think about a few important things. First, check the power the motor needs. It should match what your lathe uses. Next, look at the size of the motor to make sure it fits. Finally, consider how fast the motor can spin. This affects how your lathe works.

How Do You Determine The Correct Pulley Size For A New Lathe Motor Installation?

To find the right pulley size for your lathe motor, you need to know two things: the motor speed and the lathe speed. First, check the motor’s speed, usually in revolutions per minute (RPM). Then, divide the lathe speed by the motor speed. This gives you the ratio you need. Finally, match this ratio with pulley sizes to find the best fit.

What Are The Common Signs That Indicate A Lathe Motor Needs To Be Replaced?

You might need to replace a lathe motor if it makes strange noises. If the lathe runs slower than usual, that’s another sign. Look for sparks or smoke, too; that’s not good! Lastly, if it won’t turn on at all, it might be time for a new motor.

How Can The Efficiency Of A Metal Lathe Be Affected By The Pulley System Used With The Motor?

The pulley system helps the motor turn the lathe, like a bike chain helps turn the wheels. If the pulleys are the right size, they make everything work smoothly. But if they’re too big or too small, it can slow things down. This means you might finish your work slower, which is not efficient. So, picking the right pulleys is really important!

What Tools And Materials Are Necessary For Replacing The Motor And Pulley On A Metal Lathe?

To replace the motor and pulley on a metal lathe, you’ll need a few tools. Get a wrench set to unscrew parts. Use a screwdriver to help with tiny screws. You may also need pliers to hold or twist things. For materials, have a new motor and pulley ready to install. Don’t forget some grease for smooth movement!