Have you ever wondered how a metal lathe stays so smooth and precise? It’s all about maintenance, especially when it comes to the lathe oil change. Just like your bicycle needs oil, so does your metal lathe. When it runs on fresh oil, it works better and lasts longer.

Imagine working on a project, and suddenly, you notice something feels off. The cross slide isn’t moving as it should. It might be time for a lathe oil change. Regular oil changes can make a big difference. They keep your machine happy and your projects on track.

Did you know that many people forget about the oil until something goes wrong? This can lead to costly repairs. A simple oil change can prevent that! It’s like changing the oil in a car. If you do it right, you can save time and money in the long run.

So, are you ready to learn how to change the lathe oil? Let’s dive into the steps that will keep your metal lathe and its cross slide in great shape!

Lathe Oil Change: Maintaining Your Metal Lathe Cross Slide

Understanding Lathe Oil Change for Metal Lathe Cross Slide

Changing lathe oil is key to keeping your metal lathe cross slide in top shape. Fresh oil reduces friction and prevents wear, ensuring smooth operation. Have you ever noticed strange noises during use? It could mean your lathe needs an oil change. Regular maintenance helps prolong tool life and improve performance. Remember, a little care goes a long way in making your lathe work better and last longer. Don’t ignore those oil changes!

Understanding Lathe Oil and Its Importance

Explanation of lathe oil types and properties. Importance of regular oil changes for maintenance.

Lathe oil comes in different types, like mineral or synthetic. Each has unique properties, making them great for various tasks. Regular oil changes keep machines running smoothly. Think of it like giving your lathe a nice bath, minus the rubber duck! Changing oil helps avoid wear and tear, just like brushing your teeth prevents cavities. Remember, a happy lathe is a productive lathe!

| Type of Lathe Oil | Properties |

|---|---|

| Mineral Oil | Good for basic needs, affordable. |

| Synthetic Oil | Lasts longer, offers better protection. |

Signs Your Lathe Needs an Oil Change

Common indicators of low or dirty oil. Effects of neglecting oil maintenance on lathe performance.

Is your lathe slowing down? Signs of low or dirty oil may show up quickly. Look for these signs:

- Unusual noise during operation.

- Stiff or jerky movement of parts.

- Change in color of the oil.

Neglecting to change the oil affects performance. It can lead to overheating and damage. This can make your work harder and less precise. Regular maintenance keeps your lathe running smoothly!

What happens if you ignore oil changes?

Ignoring oil changes can lead to serious problems. Your lathe may not work properly, and parts could wear out faster. This can cost you more in repairs or replacements.

Preparing for a Lathe Oil Change

Tools and materials needed for the oil change. Safety precautions to consider before starting the process.

Before diving into an oil change, gather some handy tools. You’ll need an oil container, a syringe, and, of course, some fresh lathe oil. Safety is key! Make sure to wear gloves and goggles to keep your hands and eyes safe. It’s like wearing your superhero costume while doing maintenance! Remember, **lathe oil** keeps your machine happy and working smoothly.

| Tools and Materials | Safety Precautions |

|---|---|

| Oil container | Wear gloves |

| Syringe | Wear goggles |

| Fresh lathe oil | Keep workspace clean |

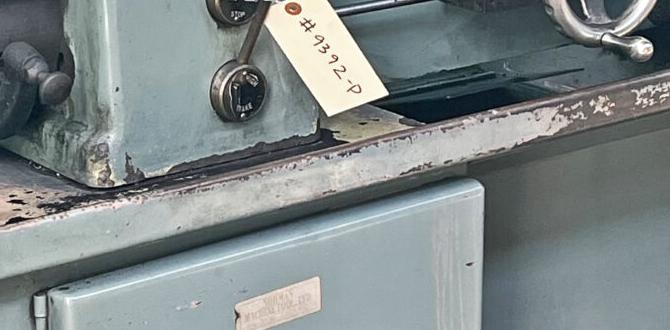

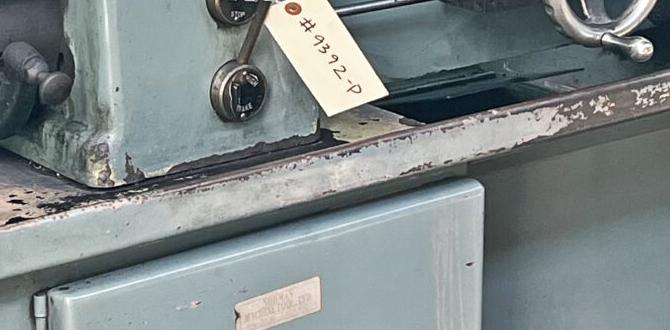

Step-by-Step Guide to Changing Oil on a Metal Lathe Cross Slide

Detailed instructions for draining old oil. How to properly clean and refill with new oil.

First, let’s drain the old oil. Find the drain plug on your lathe cross slide and twist it loose. Be careful; the oil might be messier than a toddler with spaghetti! Let it all drain into a container. Once empty, grab a clean cloth and wipe any leftover gunk. Next, refill with fresh oil. Use a funnel to avoid spills—it’s easier than cleaning up a flood! The right oil keeps your lathe happy and running smooth. Here’s a quick guide:

| Step | Action |

|---|---|

| 1 | Drain old oil |

| 2 | Wipe the area clean |

| 3 | Refill with new oil |

Choosing the Right Lathe Oil for Your Machine

Factors to consider when selecting oil (viscosity, compatibility). Recommended oil brands and types for different lathes.

Finding the right lathe oil is key to keeping your machine happy. First, consider viscosity. This term means how thick or thin the oil is. Thicker oils stay put, while thinner oils flow easily. Next, think about compatibility. Not all oils work with every lathe, so check your machine’s manual. Brands like Mobil and Mobil Delvac are popular choices. Some types, such as ISO 68 or way oil, are good bets for most lathes. Below is a handy guide:

| Lathe Type | Recommended Oil |

|---|---|

| High-Volume | Mobil 15W-40 |

| Small Hobby | ISO 68 |

| Precision | Way Oil |

Choose wisely, or your lathe might just throw a tantrum!

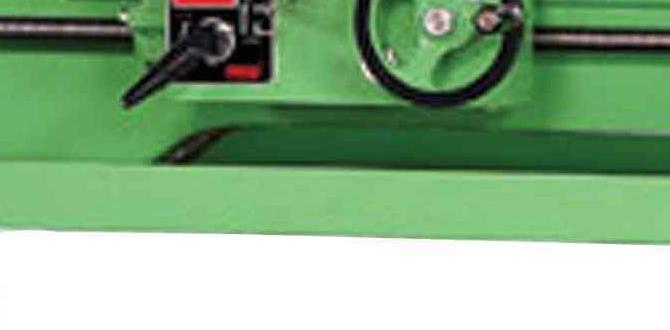

Maintenance Tips for Prolonging Lathe Lifespan

Routine checks and oiling schedules. Additional maintenance practices to keep your lathe in top condition.

To keep your lathe running well, regular checks are a must. Oil changes and maintenance help it last longer. Follow a schedule for oiling and inspections. Here are some tips:

- Check oil levels weekly.

- Clean the cross slide often.

- Look for wear on parts monthly.

- Use quality lathe oil.

Staying on top of these tasks can save time and money. A well-maintained lathe can work for years.

What are routine checks for a lathe?

Routine checks include looking at oil levels, cleaning tools, and testing for loose parts.

Why is oiling essential?

Oiling reduces friction and prevents rust.

Common Mistakes to Avoid During an Oil Change

Frequent errors lathe owners make. How to troubleshoot issues that arise during oil changes.

Changing oil in your lathe should be easy, but things can go wrong. One common mistake is forgetting to clean the old oil from the cross slide. This leads to messy results! Another error is using the wrong type of oil. Instead, choose suitable lathe oil for smooth operation. Also, don’t skip checking for leaks after the change. If you see any, you might need a new seal! Keep track of your oil change schedule; it helps in avoiding mishaps.

| Common Mistakes | Solutions |

|---|---|

| Not cleaning old oil | Always scrub it out first! |

| Wrong oil type | Use lathe-specific oil |

| Ignoring leaks | Fix seals right away! |

Frequently Asked Questions About Lathe Oil Changes

Answers to common questions. Myths vs. facts regarding lathe maintenance.

Many people have questions about changing lathe oil. Understanding these can help you care for your machine better. Here are some answers to common queries and clarify a few myths:

How often should I change lathe oil?

You should change lathe oil every 50 hours of use. Regular changes help keep your lathe running smoothly.

Is thicker oil always better?

No, thicker oil can slow down your lathe. Use the oil recommended in your machine’s manual for best results.

Can I use any oil for my lathe?

No, only use oil made for lathes. Other oils might not protect your machine properly.

- Myth: All lathes require the same oil.

- Fact: Each lathe has specific needs.

- Myth: You don’t need to check the oil level often.

- Fact: Regular checks prevent problems.

Taking care of your lathe makes it last longer and work better!

Conclusion

In summary, changing lathe oil is essential for keeping your metal lathe’s cross slide working well. Regular oil changes help prevent wear and tear. You can improve your machine’s performance by checking the oil frequently. Remember to follow the manufacturer’s guidelines. For more tips and detailed steps, look for videos or guides online. Happy machining!

FAQs

Here Are Five Related Questions Regarding Lathe Oil Change And The Metal Lathe Cross Slide:

Changing the oil in a lathe is important for keeping it running well. You should check the oil regularly. If it looks dirty or old, it’s time to change it. Always follow the instructions for your specific lathe. This helps everything move smoothly!

Sure! Just let me know what question you want me to answer.

What Type Of Oil Is Recommended For Changing The Lathe Oil In A Metal Lathe Cross Slide?

You should use light machine oil for changing the lathe oil in a metal lathe cross slide. This type of oil is thin and helps the parts move smoothly. Look for oil that is labeled for machines or tools. You can also check your lathe’s manual for specific recommendations. Using the right oil keeps your lathe working well!

How Often Should The Oil Be Changed In The Cross Slide Of A Metal Lathe To Ensure Optimal Performance?

You should change the oil in the cross slide of a metal lathe every 6 to 12 months. This keeps everything running smoothly. If you use the lathe a lot, you might need to change it more often. Always check the oil level regularly, too. This helps make your lathe work better for a long time.

What Are The Signs That Indicate It’S Time To Change The Oil In The Lathe’S Cross Slide?

You should change the oil in the lathe’s cross slide when it looks dirty or is thick like syrup. If you hear unusual noises while using the lathe, that can also be a sign. Another sign is if the cross slide feels stiff or doesn’t move smoothly. We want the oil to keep everything working well, so checking regularly helps!

Can Using The Wrong Type Of Oil Affect The Performance Of The Metal Lathe Cross Slide?

Yes, using the wrong type of oil can hurt how well the metal lathe cross slide works. Oil helps the parts move smoothly. If the oil is too thick or thin, it can make moving hard. This can cause problems and might damage the machine. Always use the right oil for the best performance.

What Is The Proper Procedure For Draining And Replacing The Oil In A Metal Lathe Cross Slide?

To change the oil in a metal lathe cross slide, first, turn off the machine and unplug it. Next, find the oil drain plug and place a container under it. Unscrew the plug to let the old oil drain out. Once it has all drained, replace the plug and fill the cross slide with new oil through the fill hole. Finally, make sure everything is tight and clean up any spills.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions Regarding Lathe Oil Change And The Metal Lathe Cross Slide:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Changing the oil in a lathe is important for keeping it running well. You should check the oil regularly. If it looks dirty or old, it’s time to change it. Always follow the instructions for your specific lathe. This helps everything move smoothly!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know what question you want me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Changing The Lathe Oil In A Metal Lathe Cross Slide?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use light machine oil for changing the lathe oil in a metal lathe cross slide. This type of oil is thin and helps the parts move smoothly. Look for oil that is labeled for machines or tools. You can also check your lathe’s manual for specific recommendations. Using the right oil keeps your lathe working well!”}},{“@type”: “Question”,”name”: “How Often Should The Oil Be Changed In The Cross Slide Of A Metal Lathe To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in the cross slide of a metal lathe every 6 to 12 months. This keeps everything running smoothly. If you use the lathe a lot, you might need to change it more often. Always check the oil level regularly, too. This helps make your lathe work better for a long time.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate It’S Time To Change The Oil In The Lathe’S Cross Slide?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in the lathe’s cross slide when it looks dirty or is thick like syrup. If you hear unusual noises while using the lathe, that can also be a sign. Another sign is if the cross slide feels stiff or doesn’t move smoothly. We want the oil to keep everything working well, so checking regularly helps!”}},{“@type”: “Question”,”name”: “Can Using The Wrong Type Of Oil Affect The Performance Of The Metal Lathe Cross Slide?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, using the wrong type of oil can hurt how well the metal lathe cross slide works. Oil helps the parts move smoothly. If the oil is too thick or thin, it can make moving hard. This can cause problems and might damage the machine. Always use the right oil for the best performance.”}},{“@type”: “Question”,”name”: “What Is The Proper Procedure For Draining And Replacing The Oil In A Metal Lathe Cross Slide?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in a metal lathe cross slide, first, turn off the machine and unplug it. Next, find the oil drain plug and place a container under it. Unscrew the plug to let the old oil drain out. Once it has all drained, replace the plug and fill the cross slide with new oil through the fill hole. Finally, make sure everything is tight and clean up any spills.”}}]}