Have you ever wondered why taking care of your metal lathe is so important? Just like any machine, a metal lathe needs regular attention. One key part of that care is changing the lathe oil. This task helps keep your cutting tools in top shape. Neglecting this step can lead to poor performance and even costly repairs.

Imagine trying to use a dull tool that keeps snagging. It’s frustrating, right? By regularly changing the lathe oil, you prevent that scenario. Fresh oil helps the tools glide smoothly, making your work easier and safer.

Did you know that clean lathe oil can also extend the life of your tools? It can save you time and money in the long run. So, if you’re ready to learn how to properly change your lathe oil, keep reading!

Lathe Oil Change: Essential For Metal Lathe Cutting Tools

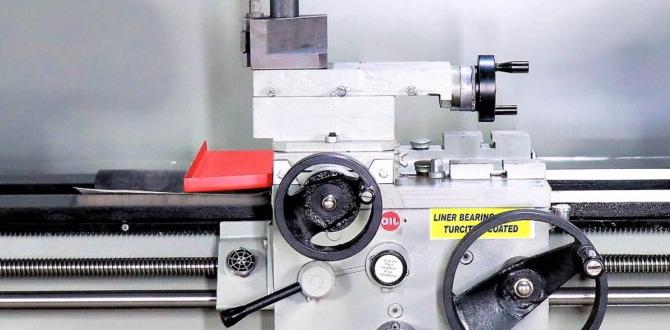

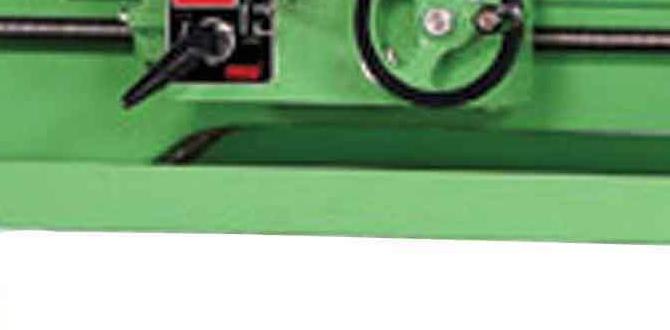

Understanding Lathe Oil Change for Metal Lathes

Keeping your metal lathe well-lubricated is essential. Regular lathe oil changes help maintain cutting tools, ensuring they work efficiently. Did you know that fresh oil can significantly improve the quality of your cuts? It also protects against rust and wear. When to change the oil? Look for signs like unusual noise or sluggish performance. By staying on top of oil changes, you can extend the life of your tools and enhance your projects!Understanding Lathe Oil

Definition and importance of lathe oil in machining. Different types of lathe oils and their properties.Lathe oil is like the secret sauce for your metal lathe! It helps tools cut smoothly and keeps everything running smoothly. Think of it as a superhero for your machines. There are different types of lathe oils, each with unique properties. Some help reduce friction, while others prevent rust. Choosing the right oil can make your lathe feel like it’s on roller skates!

| Type of Lathe Oil | Key Properties |

|---|---|

| Mineral Oil | Great for lubrication and heat resistance |

| Synthetic Oil | Offers excellent protection against wear |

| Cutting Oils | Reduces friction and cools the tool |

Every time you change your lathe oil, you give your metal cutting tools a better chance to shine. So, don’t let your lathe run dry—keep it happy with some fresh oil!

Signs That Your Lathe Oil Needs Changing

Indicators of degraded oil performance. Effects of old oil on metal lathe cutting tools.When your lathe oil starts acting funny, it’s time to pay attention. Look for signs like a dark color or a strange smell—these are big clues that your oil has seen better days. If your metal lathe cutting tools are beginning to wear down faster than a kid at a candy shop, old oil might be the culprit. Fresh oil helps protect tools and keeps them sharp. Remember, a happy lathe means happy tools!

| Signs of Degraded Oil | Effects on Cutting Tools |

|---|---|

| Dark color | Increased wear |

| Unpleasant smell | Shorter lifespan |

| Thick consistency | Less efficiency |

How Often to Change Lathe Oil

Recommended oil change intervals based on usage. Factors that influence oil change frequency.Changing lathe oil is key to keeping your lathe running smoothly. Generally, it’s good to check and change the oil every 25-50 hours of operation, especially for heavy use. Light users might change it every few months. Factors that can influence how often you should change the oil include:

- Machine usage intensity

- Type of materials being cut

- Environmental conditions

Regular checks ensure that your lathe functions well and lasts longer. Stay ahead by keeping an eye on oil quality!

How often should lathe oil be changed?

For regular users, change lathe oil every 25-50 hours of use. Light users can wait a couple of months for change.

Tools and Materials Needed for Lathe Oil Change

Essential tools for changing lathe oil. Recommended types of lathe oil for metal lathes.To change lathe oil, you’ll need a few simple tools. Start with an oil drain pan to catch used oil. A wrench helps to remove the drain plug. Use a funnel for easy pouring of new oil. Finally, have a clean rag for wiping spills.

For your metal lathe, it’s important to choose the right oil. Consider these types:

- Way Oil: Great for lubrication.

- ISO Grade 32 or 46: Works well for most lathes.

- Hydraulic Oil: Good for cooling and lubrication.

What type of oil should I use for my metal lathe?

For a metal lathe, way oil or ISO 32/46 grade oil is best.

Step-by-Step Guide to Changing Lathe Oil

Detailed procedure for draining old oil. Instructions for cleaning and refilling with new oil.Changing lathe oil is essential for keeping your metal lathe running smoothly. Here’s how you can do it:

- First, turn off the lathe and unplug it.

- Locate the oil drain plug, usually found at the bottom of the oil reservoir.

- Place a container under the plug and remove it to drain the old oil.

- Once drained, clean the reservoir with a cloth or paper towel.

- Replace the drain plug tightly.

- Now, refill the reservoir with fresh lathe oil through the fill hole.

- Check the oil level using the dipstick, if your lathe has one.

And that’s it! Regular oil changes help your lathe cut smoothly and last longer.

How often should you change lathe oil?

It is recommended to change lathe oil every 100 operating hours or at least once a year. This keeps your machine in good shape and helps avoid costly repairs.

Best Practices for Lathe Maintenance

Additional maintenance tips for metal lathe cutting tools. How proper oil change contributes to tool longevity.Keeping your metal lathe running well is key. Here are some great tips to help you care for your cutting tools:

- Always check for dirt and chips. Clean your tool after each use.

- Change the lathe oil regularly. This keeps everything smooth and helps tools last longer.

- Inspect parts for wear and tear. It helps catch problems early.

Remember, proper oil changes can boost your tool’s life by up to 50%. This simple step can save you time and money.

Why is regular oil change important?

Regular oil changes help keep your metal lathe in top shape. They reduce friction and prevent rust, which means tools can cut better and last longer.

Common Mistakes to Avoid During Lathe Oil Change

Typical errors that can compromise lathe performance. Solutions to prevent oil change mishaps.Changing lathe oil is essential for smooth operation. Some common mistakes can hurt your lathe’s performance. Here are important ones to watch out for:

- Using the wrong type of oil can cause damage.

- Not checking for old oil can lead to dirt buildup.

- Skipping regular changes may wear out your machine.

To prevent these mishaps:

- Always use the recommended oil type.

- Inspect and change oil regularly.

- Keep your tools clean and well-maintained.

These tips will help keep your lathe running like new.

What can go wrong if I change the oil incorrectly?

Changing lathe oil incorrectly may cause poor performance, increased wear, and machine failures. Regular maintenance is key to keeping tools working well.

FAQs About Lathe Oil and Maintenance

Common questions and expert answers regarding lathe oil. Troubleshooting tips for oilrelated issues on metal lathes.Many people have questions about lathe oil and how to keep tools in good shape. Here are some common ones:

What type of oil should I use for my lathe?

Use a high-quality machine oil specially designed for lathes. This oil protects metal parts and keeps them running smoothly.

How often should I change the lathe oil?

Change lathe oil every 50 hours of work or at least once a month. Regular changes keep your lathe in optimal condition.

What to do if the lathe oil looks dirty?

Change the oil immediately. Dirty oil can harm your machine.

Troubleshooting Oil-Related Issues

- Check for leaks if oil levels drop.

- Ensure proper oiling when the lathe is in use.

- Inspect the oil filter for clogs.

Regular maintenance of lathe oil keeps your cutting tools working well and helps them last longer. Keep these tips in mind for a trouble-free experience!

Conclusion

In summary, changing lathe oil is crucial for keeping your metal lathe in top shape. Clean oil helps your cutting tools work better and last longer. Always check and replace oil regularly. Remember, good maintenance keeps your projects running smoothly. For more tips, consider reading about proper lathe care or watch videos on tool maintenance. You’ll enjoy better results!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change And Metal Lathe Cutting Tools:Sure! Changing lathe oil helps keep the machine running smoothly. You should do it regularly to avoid problems. When you use metal cutting tools, they can wear out. Check them often to make sure they stay sharp. If a tool is dull, it’s better to replace it for cleaner cuts.

Sure! Please share the question you want me to answer.

What Type Of Oil Is Recommended For Lubricating A Metal Lathe, And How Often Should It Be Changed?You should use a light machine oil for lubricating a metal lathe. It helps the parts move smoothly. Change the oil every few months or when it looks dirty. Always check the oil level to keep your lathe working well.

How Do I Properly Change The Oil In My Metal Lathe, And What Steps Should I Follow To Ensure The Lathe Functions Optimally?To change the oil in your metal lathe, start by turning off the machine and unplugging it. Next, find the oil drain plug and let the old oil pour out into a container. Then, replace the drain plug and add new oil to the fill hole. Make sure to use the right type of oil for your lathe. Finally, run the lathe for a few minutes to help the new oil spread, and check for leaks.

What Are The Signs That Indicate The Oil In A Lathe Needs To Be Replaced, And What Are The Potential Consequences Of Neglecting This Maintenance?You should check the oil in a lathe if it looks dirty, dark, or has a strange smell. If the oil level is low, that’s another sign. If you ignore these signs, the lathe might not work well. This could cause damage and make the machine break down. Regular oil changes keep everything running smoothly.

How Can The Use Of Appropriate Cutting Tools Affect The Frequency Of Oil Changes In A Metal Lathe?Using the right cutting tools helps the metal lathe work better. When tools cut smoothly, they create less heat. Less heat means less wear on the machine and its parts. This helps the oil last longer, so you won’t need to change it as often. Overall, good tools keep everything running smoothly and save you time.

What Specific Maintenance Practices Should Be Followed For Different Types Of Metal Lathe Cutting Tools To Ensure Their Longevity And Optimal Performance?To keep metal lathe cutting tools in great shape, you should clean them after each use. Use a soft cloth to wipe off any dirt or metal shavings. Check the sharpness of the tools regularly; if they are dull, sharpen them. Store your tools in a dry place to avoid rust. Finally, make sure to oil them lightly to keep them smooth and working well.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change And Metal Lathe Cutting Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Changing lathe oil helps keep the machine running smoothly. You should do it regularly to avoid problems. When you use metal cutting tools, they can wear out. Check them often to make sure they stay sharp. If a tool is dull, it’s better to replace it for cleaner cuts.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating A Metal Lathe, And How Often Should It Be Changed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use a light machine oil for lubricating a metal lathe. It helps the parts move smoothly. Change the oil every few months or when it looks dirty. Always check the oil level to keep your lathe working well.”}},{“@type”: “Question”,”name”: “How Do I Properly Change The Oil In My Metal Lathe, And What Steps Should I Follow To Ensure The Lathe Functions Optimally?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in your metal lathe, start by turning off the machine and unplugging it. Next, find the oil drain plug and let the old oil pour out into a container. Then, replace the drain plug and add new oil to the fill hole. Make sure to use the right type of oil for your lathe. Finally, run the lathe for a few minutes to help the new oil spread, and check for leaks.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate The Oil In A Lathe Needs To Be Replaced, And What Are The Potential Consequences Of Neglecting This Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the oil in a lathe if it looks dirty, dark, or has a strange smell. If the oil level is low, that’s another sign. If you ignore these signs, the lathe might not work well. This could cause damage and make the machine break down. Regular oil changes keep everything running smoothly.”}},{“@type”: “Question”,”name”: “How Can The Use Of Appropriate Cutting Tools Affect The Frequency Of Oil Changes In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using the right cutting tools helps the metal lathe work better. When tools cut smoothly, they create less heat. Less heat means less wear on the machine and its parts. This helps the oil last longer, so you won’t need to change it as often. Overall, good tools keep everything running smoothly and save you time.”}},{“@type”: “Question”,”name”: “What Specific Maintenance Practices Should Be Followed For Different Types Of Metal Lathe Cutting Tools To Ensure Their Longevity And Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep metal lathe cutting tools in great shape, you should clean them after each use. Use a soft cloth to wipe off any dirt or metal shavings. Check the sharpness of the tools regularly; if they are dull, sharpen them. Store your tools in a dry place to avoid rust. Finally, make sure to oil them lightly to keep them smooth and working well.”}}]}