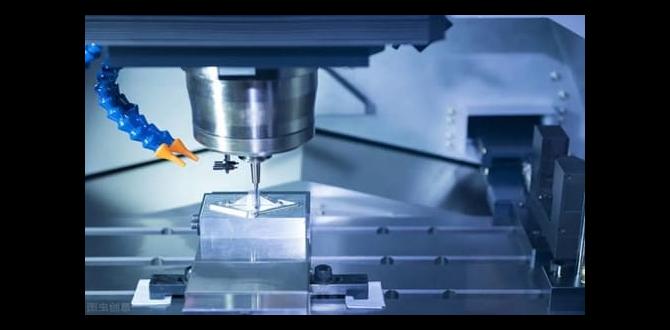

Have you ever wondered how a metal lathe works smoothly? It’s all about keeping it well-oiled. If you use a metal lathe, you may need to change the lathe oil from time to time. This simple task can make a big difference in how your machine performs.

Picture this: you’re in the workshop, creating your next big project. Suddenly, the lathe starts making weird noises, or it just doesn’t feel right. This can happen if the lathe oil is old or dirty. Changing the oil is an easy way to keep your lathe running like new.

Did you know that using the right oil can help your lathe last longer? Many people don’t realize how important the lathe oil change is. It’s not just about keeping things lubricated; it’s about protecting your investment.

In this article, we will explore the steps to change lathe oil and keep your metal lathe saddle in top shape. Let’s dive in and learn how to make your tool work better while having fun in the process!

Essential Guide To Lathe Oil Change For Metal Lathe Saddle

Lathe Oil Change for Metal Lathe Saddle

Keeping your metal lathe saddle well-oiled is essential for smooth operation. Changing lathe oil regularly prevents rust and keeps parts from wearing down too quickly. Did you know that using the right oil can extend the life of your machine? First, clean the area to avoid dirt contamination. Then, use quality lathe oil, ensuring even distribution. Small steps like this can save you money and time in the long run. Happy machining!Understanding Lathe Oil

Definition and purpose of lathe oil. Different types of lathe oils available.Lathe oil is a special lubricant used in metal lathes. Its main job is to keep parts moving smoothly. This oil prevents rust and reduces friction. There are different types of lathe oils, each serving unique needs. Here are some common types:

- Way oil: Good for slides and ways.

- Cutting oil: Helps with metal cutting and prevents overheating.

- Spindle oil: Ideal for high-speed spindles.

Using the right lathe oil is key for a machine’s performance and long life. Always check your machine’s needs!

What is the purpose of lathe oil?

Lathe oil helps machines run smoothly and prevents parts from wearing out.What types of lathe oils are available?

Common Lathe Oils:

- Way Oil

- Cutting Oil

- Spindle Oil

Importance of Regular Oil Changes

Benefits of maintaining oil quality. How oil affects lathe performance.Changing lathe oil regularly is like giving your machine a refreshing drink! Clean oil helps keep everything moving smoothly. It not only protects your lathe but also boosts its performance. Think of it as a spa day for your metal lathe. Dirty oil can lead to wear and tear, shortening its life. Remember, happy lathe, happy maker!

| Benefit | Description |

|---|---|

| Longer Lathe Life | Fresh oil reduces wear and tear. |

| Smoother Operation | Quality oil ensures better performance. |

| Cost-Effective | Less chance of costly repairs! |

Signs That Your Metal Lathe Needs an Oil Change

Visual indicators of oil degradation. Performance issues due to old oil.Look for signs that your metal lathe needs an oil change. Check for these visual indicators:

- Oil looks dark or dirty.

- Unusual smells coming from the lathe.

- Visible sludge or particles in the oil.

Old oil can cause performance issues. You might notice:

- The lathe makes strange noises.

- Parts of the lathe feel rough or sticky.

- Workpieces do not turn smoothly.

Pay attention to these signs to keep your lathe running well.

How often should I change oil in my lathe?

You should change the oil every 3 to 6 months. This will help keep your lathe in top shape.

Tools and Materials Required for an Oil Change

List of essential tools. Recommended oil types for different lathe models.For a smooth oil change on your lathe, you’ll need some essential tools. Grab a wrench, a container for old oil, and a funnel to avoid messy spills. Don’t forget gloves — oil can be slippery! Different lathe models need specific oils. Here’s a quick guide:

| Lathe Model | Recommended Oil |

|---|---|

| Model A | SAE 20 |

| Model B | ISO 32 |

| Model C | Way Oil 68 |

Using the right oil helps keep your lathe in top shape. Remember, a happy lathe means happy turning!

Step-by-Step Process for Changing Lathe Oil

Detailed procedure for draining old oil. Instructions for adding new oil.Changing the lathe oil is simple. First, drain the old oil. To do this, follow these steps:

- Locate the drain plug under the lathe.

- Prepare a clean container to catch the oil.

- Remove the drain plug carefully.

- Let the old oil flow out completely.

Once the oil is drained, add the new oil:

- Check your machine’s manual for the correct oil type.

- Use a funnel for easy pouring.

- Fill the oil reservoir until it reaches the mark.

- Replace the drain plug securely.

What is the best type of oil for my lathe?

The best type of oil varies by machine. Always refer to your lathe’s manual for specific recommendations.Specific Considerations for Saddle Maintenance

How to ensure proper lubrication for the saddle. Common issues related to saddle oiling.To keep a metal lathe saddle working well, proper lubrication is key. Without it, problems arise. Make sure to check the oil level regularly. This ensures smooth operations. Here are some common issues:

- Oil leaks can cause poor performance.

- Old oil may not lubricate well.

- Dirt can build up and affect movement.

Regular maintenance keeps the saddle running smoothly for a long time. A well-lubricated saddle helps avoid costly repairs and ensures safety.

How often should I change the oil in my lathe saddle?

It’s best to change the oil every 1-3 months, depending on usage. Regular checks help catch leaks early, ensuring your lathe works smoothly.

Safety Precautions to Follow During Oil Change

Personal protective equipment (PPE) recommendations. Best practices for minimizing hazards.Changing oil safely is important. Always wear your personal protective equipment (PPE). This includes gloves, safety goggles, and a face mask. These items protect you from spills and harmful fumes. Here are some best practices:

- Keep your workspace clean and organized.

- Use spill trays to catch any oil.

- Ensure good ventilation.

- Read the oil change instructions carefully.

These tips help reduce the chance of accidents. Always think about safety first!

What is the best personal protective equipment for an oil change?

Personal protective equipment (PPE) includes gloves, goggles, and masks. These items help keep you safe from oils and chemicals.

Maintenance Tips for Optimal Lathe Performance

Routine checks to accompany oil changes. Recommended oil change frequency based on usage.To keep your lathe running smoothly, regular checks are key. Look for any unusual noises or squeaks that might hint at trouble. Checking the belts and gears can prevent bigger issues down the road. As for oil changes, it’s best to do this every 50 hours of heavy use or every few months if you’re using it less. Remember, stale oil is like leftover pizza: it’s never good! Use the table below for a quick overview:

| Usage Level | Oil Change Frequency |

|---|---|

| Heavy Use | Every 50 hours |

| Moderate Use | Every 3 months |

| Light Use | Every 6 months |

Sticking to this schedule ensures peak performance. So, check those levels and change that oil! Your lathe will thank you with smooth turns and happy projects.

FAQ About Lathe Oil Changes

Common questions and expert answers. Troubleshooting tips for common issues.Many people have questions about changing lathe oil. Here are some common inquiries:

What is the purpose of lathe oil?

Lathe oil keeps the machine running smoothly. It reduces friction and helps prevent wear and tear on parts.

How often should I change the oil?

Change the oil every 100 hours of use or once a month. Regular changes help keep your lathe in good shape.

What should I check during an oil change?

- Look for old oil that might be dark or dirty.

- Check seals for leaks.

- Make sure all parts are clean.

By following these tips, you can keep your lathe machine running well and avoid common problems.

Resources for Further Learning

Recommended books and guides. Online forums and communities for lathe enthusiasts.If you’re eager to dive deeper into the world of lathes, you are in luck! There are many excellent books and guides available. These resources can make you feel like a lathe wizard in no time. Don’t forget to join online forums. There, you can chat with fellow lathe lovers about everything from oil changes to the best tools. Plus, sharing a laugh over lathe mishaps never hurts! Here’s a little table to help you kickstart your learning journey:

| Resource Type | Recommended Titles |

|---|---|

| Books | The Lathe Book, Metalworking Sink or Swim |

| Online Forums | Practical Machinist, Reddit’s r/Machinists |

With these tips and resources, you’ll be changing that lathe oil like a pro in no time!

Conclusion

In summary, changing the lathe oil in your metal lathe saddle keeps it running smoothly. Regular oil changes prevent wear and tear on moving parts. Remember to check the oil level often. If you’re unsure about how to change it, there are plenty of guides online. Let’s keep your lathe in top condition for great projects ahead!FAQs

Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Saddle:To change the oil in a metal lathe saddle, first, find the oil drain plug. You will need to unscrew it carefully. Let the old oil flow out into a container. Next, pour in the new oil until it reaches the right level. Make sure to check it regularly to keep it working smoothly!

Sure! Please provide the question you would like me to answer.

What Type Of Oil Is Recommended For Changing The Lubricant In A Metal Lathe Saddle?For changing the oil in a metal lathe saddle, you should use a light machine oil. This oil keeps the parts working smoothly. Make sure it is clean and free of dirt. You can find this oil at most hardware stores. Always check your machine’s manual for any special recommendations.

How Often Should The Oil Be Changed In A Metal Lathe Saddle To Ensure Optimal Performance?You should change the oil in a metal lathe saddle every 100 hours of use. This helps the lathe run smoothly. If you use it a lot, check more often. Keeping the oil fresh makes your lathe last longer and work better. Always follow the instructions for your specific lathe.

What Steps Should Be Followed To Properly Change The Oil In A Metal Lathe Saddle?To change the oil in a metal lathe saddle, first, turn off the machine and unplug it. Next, find the oil drain plug and carefully remove it. Let the old oil drain out into a container. After that, replace the plug and add fresh oil through the fill hole. Finally, clean up any mess and check the oil level before using the lathe again.

Are There Any Signs That Indicate It’S Time To Change The Oil In The Lathe Saddle?Yes, there are signs that show it’s time to change the oil in the lathe saddle. If you notice unusual noises while using the lathe, that can mean the oil is old. If the oil looks dirty or thick, it needs to be changed too. Also, if the lathe isn’t moving smoothly, that’s a sign to check the oil. Keeping the oil fresh helps your lathe work better.

How Can Improper Oil Maintenance Affect The Longevity And Performance Of A Metal Lathe?If you don’t take care of the oil in a metal lathe, it can cause problems. The machine might get rusty or dirty. This can make the lathe work poorly and break down faster. When we change the oil and keep it clean, the lathe lasts longer and works better. So, proper oil maintenance is really important!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Oil Change For A Metal Lathe Saddle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in a metal lathe saddle, first, find the oil drain plug. You will need to unscrew it carefully. Let the old oil flow out into a container. Next, pour in the new oil until it reaches the right level. Make sure to check it regularly to keep it working smoothly!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Changing The Lubricant In A Metal Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “For changing the oil in a metal lathe saddle, you should use a light machine oil. This oil keeps the parts working smoothly. Make sure it is clean and free of dirt. You can find this oil at most hardware stores. Always check your machine’s manual for any special recommendations.”}},{“@type”: “Question”,”name”: “How Often Should The Oil Be Changed In A Metal Lathe Saddle To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should change the oil in a metal lathe saddle every 100 hours of use. This helps the lathe run smoothly. If you use it a lot, check more often. Keeping the oil fresh makes your lathe last longer and work better. Always follow the instructions for your specific lathe.”}},{“@type”: “Question”,”name”: “What Steps Should Be Followed To Properly Change The Oil In A Metal Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in a metal lathe saddle, first, turn off the machine and unplug it. Next, find the oil drain plug and carefully remove it. Let the old oil drain out into a container. After that, replace the plug and add fresh oil through the fill hole. Finally, clean up any mess and check the oil level before using the lathe again.”}},{“@type”: “Question”,”name”: “Are There Any Signs That Indicate It’S Time To Change The Oil In The Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are signs that show it’s time to change the oil in the lathe saddle. If you notice unusual noises while using the lathe, that can mean the oil is old. If the oil looks dirty or thick, it needs to be changed too. Also, if the lathe isn’t moving smoothly, that’s a sign to check the oil. Keeping the oil fresh helps your lathe work better.”}},{“@type”: “Question”,”name”: “How Can Improper Oil Maintenance Affect The Longevity And Performance Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you don’t take care of the oil in a metal lathe, it can cause problems. The machine might get rusty or dirty. This can make the lathe work poorly and break down faster. When we change the oil and keep it clean, the lathe lasts longer and works better. So, proper oil maintenance is really important!”}}]}