Have you ever watched a metal lathe in action? It’s a fascinating machine! But did you know that keeping it in good shape is super important? That’s where lathe oil comes in. Just like a car needs an oil change, your metal lathe does too. Regular maintenance helps it run smoothly.

Many beginners wonder about the best way to set up their lathe. Proper setup can make a huge difference in your projects. Imagine how frustrating it is when a tool fails during a critical moment! By learning how and when to change the oil, you can avoid those mishaps.

For those new to metalworking, the idea of lathe oil can feel confusing at first. What kind should you use? How often should you change it? The answers are simpler than you might think. With the right tips, you’ll keep your lathe humming along happily. Let’s dive into the world of lathe oil change and discover how to set up your metal lathe like a pro!

Essential Lathe Oil Change For Metal Lathe Setup Excellence

Lathe Oil Change and Metal Lathe Setup

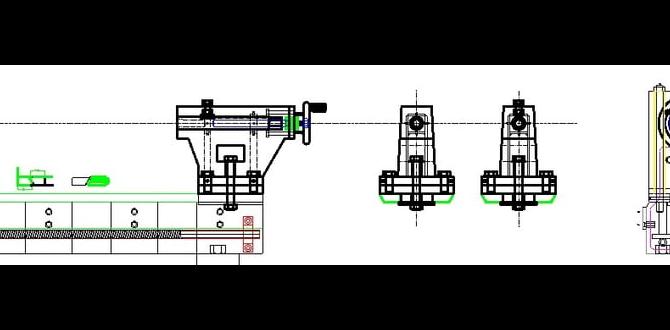

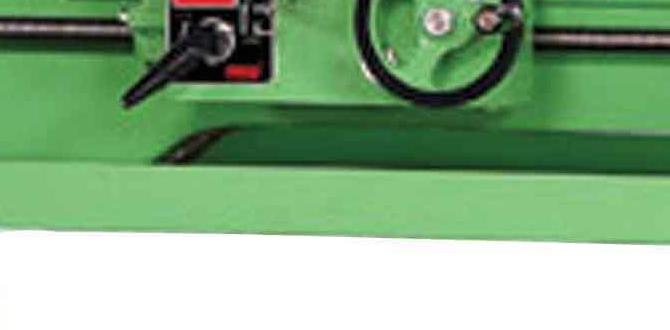

Changing the oil in a metal lathe is crucial for smooth operation. Proper lubrication prevents wear and tear on vital parts. To set up a lathe, begin by securing the machine on a stable surface. This ensures accuracy when crafting items. Remember to check the oil level regularly. Did you know that clean oil can extend the life of your lathe by years? Taking these steps helps your projects succeed and keeps your tools in top shape.Importance of Regular Lathe Oil Changes

Effects of oil degradation on machine performance. Benefits of using fresh oil for lubrication and maintenance.Changing the lathe oil regularly is super important. Old oil can turn into a gooey mess, leaving your machine feeling sluggish and grumpy. This can lead to worn-out parts and costly repairs—yikes! Fresh oil, on the other hand, helps everything run smoothly and efficiently. It’s like giving your lathe a nice spa day! Plus, it keeps pesky dirt and grime away, so your machine stays happy and healthy.

| Old Oil Effects | Fresh Oil Benefits |

|---|---|

| Sluggish performance | Smoother operations |

| Increased wear and tear | Extended machinery life |

| Dirt buildup | Cleaner working parts |

Signs Your Lathe Oil Needs Changing

Visual indicators of oil contamination. Performance issues linked to old oil.It’s time to pay attention! If you notice the oil in your lathe has turned a strange color or looks dirty, it’s waving a red flag. Clear oil should be your best friend! Also, keep an ear out for strange noises from your machine—like it’s trying to sing an off-key tune. Old oil can make your lathe grunt and groan instead of running smoothly. If performance drops, it might be time for an oil change, or your lathe may just be grumbling about last night’s dinner!

| Sign | What It Means |

|---|---|

| Dirty or discolored oil | Oil is contaminated and needs changing! |

| Strange noises | Your lathe is complaining—change the oil! |

| Poor performance | Time for an oil swap! |

Step-by-Step Guide to Changing Lathe Oil

Required tools and materials for oil change. Detailed procedure for draining and replacing oil.Changing the oil in your lathe may sound like a chore, but it’s easier than pie! First, gather your tools: an oil pan, a wrench, and, of course, fresh lathe oil. You should wear gloves unless you enjoy the smell of oil. To drain the old oil, find the drain plug and twist it off. Let it flow into the pan until empty, then put the plug back on. Next, pour new oil in—like filling a giant drink! Now your lathe is ready to roll!

| Tools | Materials |

|---|---|

| Oil Pan | Lathe Oil |

| Wrench | Gloves (optional but helpful!) |

Best Practices for Metal Lathe Maintenance

Regular maintenance schedule and oil change frequency. Additional tips for keeping your lathe in top condition.To keep your metal lathe running smoothly, follow a regular maintenance schedule. Change the oil every 40 hours of use. This helps prevent wear and tear. Clean your lathe often. Dust and metal shavings can cause problems. Make sure to check belts and screws, tightening them if needed.

- Check oil levels weekly.

- Keep the lathe clean after every use.

- Inspect for rust and clean it immediately.

- Lubricate moving parts regularly.

By doing these simple tasks, your lathe will stay in great shape. A well-maintained lathe lasts longer and works better!

How often should I change the oil in my lathe?

Change the oil every 40 hours of use to keep it running smoothly.What else can I do to maintain my lathe?

Make sure to clean it often and check belts and screws.Common Mistakes to Avoid During Oil Change

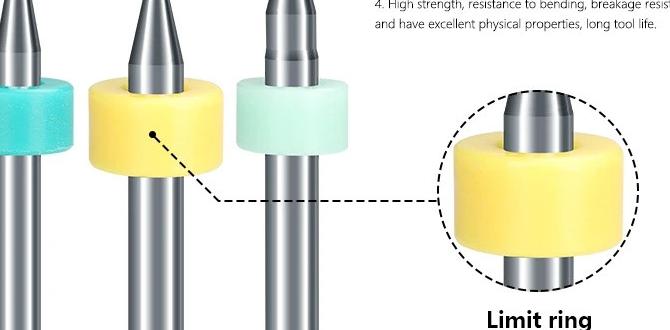

Incorrect oil types and their impact. Neglecting to clean the oil reservoir.Many people make mistakes with their oil changes. Choosing the wrong oil can hurt your machine’s performance. Always check the type needed for your lathe. Also, skipping the oil reservoir cleaning can lead to dirt buildup. This dirt can mix with oil and cause damage. Keep it clean for better performance!

What oil should you use for your lathe?

You should use the oil type recommended in your lathe’s manual. This ensures smooth operation and long life for your machine.

Frequently Asked Questions About Lathe Oil Changes

Common queries from novice and experienced machinists. Clarifications on oil specifications and usage.Many people wonder about lathe oil changes. It’s important for keeping your machine running well. Novice and experienced machinists often ask similar questions. The right oil can make a big difference in performance. Here are some common queries:

What type of oil should I use?

The best oil depends on your lathe. Always refer to your machine’s manual. It usually recommends the right oil type. For most, a high-quality lubricant works well.

How often should I change the oil?

Generally, you should check the oil every month. Replace it more often if you use the lathe a lot. Keeping oil fresh helps the lathe work better.

- Check oil level regularly.

- Change oil after heavy use.

- Follow the manual’s advice.

Resources for Further Learning

Recommended books and online resources for lathe maintenance. Community forums and workshops for practical advice.Learning about lathe maintenance doesn’t have to be dull! Grab a few engaging books that explain everything from oil changes to setup tips. The internet is full of helpful sites too. Joining community forums can turn you into a lathe expert faster than you can say “sawdust!” You can share ideas, ask questions, and even meet your next buddy who loves metalwork. Here’s a tidy table with some great resources:

| Resource Type | Recommended Source |

|---|---|

| Books | “The Metal Lathe” by David J. Gingery |

| Online Courses | Udemy’s Metalworking Courses |

| Forums | Metal Meet |

| Workshops | Local Maker Spaces |

Keep your tools clean, your mind open, and your jokes ready. After all, what’s a lathe without a little laughter?

Conclusion

In summary, changing lathe oil is crucial for keeping your metal lathe running smoothly. A proper setup helps prevent wear and tear. Always check oil levels before starting work. By understanding these steps, you ensure better performance and longer tool life. For more tips, explore resources online or ask a mentor to develop your skills further!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Oil Change And Metal Lathe Setup:To change the oil in a lathe, first, turn off the machine. Then, find the oil drain and empty the old oil. After that, refill it with new lathe oil. Finally, check that everything is clean and ready to go. This helps the lathe work well and last longer.

Sure! Please provide the question you want me to answer.

What Type Of Oil Is Recommended For Use In Metal Lathes, And How Often Should It Be Changed?For metal lathes, we should use a type of oil called machine oil. This oil helps the machine run smoothly and prevents rust. You should change the oil every three to six months. Always check the oil level regularly to keep everything working well!

How Can I Determine If My Lathe Oil Needs To Be Changed Or Topped Up?You can check your lathe oil by looking at its color and smell. If it’s dark or smells bad, it’s time to change it. You should also check the oil level. If it’s low, you can add more oil. Always make sure to check before using your lathe.

What Are The Steps To Properly Change The Oil In My Metal Lathe?To change the oil in your metal lathe, first, make sure the machine is turned off and cool. Then, find the oil drain plug and remove it to let the old oil flow out. Next, clean the oil filter if your lathe has one. After that, add new oil through the fill hole until it reaches the right level. Finally, replace the plug and clean up any spills!

Are There Specific Considerations For Setting Up A Lathe When Switching To A Different Type Of Oil?When you switch to a different type of oil for the lathe, you need to do a few things. First, clean the lathe to remove old oil. Next, check the oil type to make sure it suits your lathe. Then, fill it with the new oil and run the lathe for a bit. This helps the oil spread everywhere and work well.

How Does The Lubrication System Of A Metal Lathe Affect Its Performance And Longevity?The lubrication system in a metal lathe helps keep parts moving smoothly. When we use oil or grease, it reduces friction. Less friction means the machine works better and lasts longer. If we don’t lubricate, parts can get sticky and wear out quickly. So, good lubrication keeps the lathe running like new!