Have you ever wondered how a metal lathe works? It can turn raw metal into amazing shapes! But, like any machine, it needs care and attention. One important task is the lathe oil change. This job helps keep the lathe running smoothly and safely.

Think of your metal lathe as a car. Cars need oil changes to run well. Similarly, a well-oiled lathe can work better while threading and shaping metal. If you forget to change the oil, you may face problems.

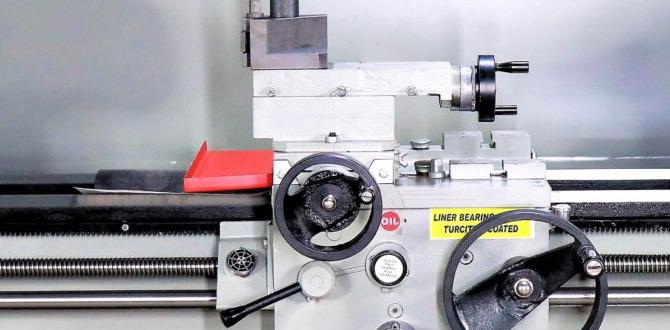

Did you know that the threading dial on a lathe plays a crucial role? It helps you create precise threads for screws and bolts. If your lathe oil is low or dirty, the threading dial may not work correctly. Imagine trying to build something and finding out that your tools aren’t working right!

In this article, we’ll talk about how to change lathe oil and keep your metal lathe in great shape. Get ready to learn a few tips that could lead you to become a lathe expert!

How To Perform A Lathe Oil Change For Metal Lathe Threading Dial

Lathe Oil Change and Metal Lathe Threading Dial

Changing lathe oil on your metal lathe is important for smooth operation. Regular oil changes keep your machine running well and reduce wear and tear. Have you ever struggled with a threading dial? A proper oil change can help it work more effectively. Think of it as giving your lathe a little TLC. Fun fact: clean oil can prevent rust, extending the life of your tool. Keeping up with maintenance not only saves you money but also helps you create better projects!Understanding Lathe Oil

Importance of lubricants in metalworking. Types of oils suitable for metal lathes.Lubricants act like the oil in a squeaky machine. They keep everything running smoothly. In metalworking, using the right oil is super important. It reduces friction and heat, making your lathe last longer. Want your lathe to dance instead of squeal? Well, choosing the right type helps! Some popular oils include cutting oil and way oil. Here’s a quick look at what to use:

| Type of Oil | Best Use |

|---|---|

| Cutting Oil | Good for threading and cutting metals. |

| Way Oil | Perfect for keeping the ways smooth. |

| Synthetic Oil | Great for tough jobs and high heat. |

Using the right lubricant means less wear and tear. Remember, a little oil makes a big difference!

Signs You Need an Oil Change

Indicators of dirty or old oil. Performance changes in threading operations.Look out for oil that looks like it’s been swimming in a mud puddle. If it’s dark and gritty, it’s time for a change! You might also notice your metal lathe struggling during threading operations. Is it making weird noises or slipping? That’s like your lathe saying, “Help! I need some fresh oil!” Regular checks keep everything running smoothly and stop those pesky performance dips.

| Signs of Old Oil | Effects on Performance |

|---|---|

| Dark color | Sluggish threading |

| Metal shavings present | Unusual grinding sounds |

| Sticky texture | Inconsistent cuts |

Step-by-Step Oil Change Process

Tools and materials needed for the oil change. Detailed procedure for draining and replacing oil.Changing oil is easy and important for your metal lathe. First, gather your tools and materials. You will need:

- New lathe oil

- Wrench

- Oil pan

- Funnel

- Rags for cleanup

Now, follow these steps to change the oil:

- Turn off the lathe and let it cool.

- Place the oil pan under the oil drain.

- Use the wrench to open the drain plug.

- Let the old oil drain completely.

- Replace the drain plug and tighten it.

- Use the funnel to pour new oil into the lathe.

- Close the oil fill cap.

This process keeps your lathe running smoothly. A well-oiled lathe helps in metal lathe threading and extends its life!

What tools do I need for an oil change?

You will need lathe oil, a wrench, an oil pan, a funnel, and rags for cleanup. It’s simple to collect these items!

Choosing the Right Oil for Your Metal Lathe

Factors to consider when selecting lathe oil. Recommended brands and oil specifications.Choosing the right oil for your metal lathe is important. The right oil helps your machine run smoothly and last longer. Here are factors to think about:

- Type of Operations: Consider what you will be using the lathe for, like threading or turning.

- Viscosity: This is how thick the oil is. Thicker oil works better for heavy tasks.

- Temperature: The oil should work well at your shop’s temperature.

Some recommended brands include Mobil, Chevron, and Castrol. Look for oils specifically made for lathes, which often have numbers like ISO 32, 68, or similar. These specifications tell you about the oil’s thickness and properties.

What type of oil is best for a lathe?

The best type of oil for a lathe is a dedicated lathe oil. This oil reduces wear and keeps the machine clean. Many people prefer oils with higher viscosity for heavy tasks.

Maintenance Tips for Longevity of Your Lathe

Regular inspection and cleaning routines. Best practices to enhance threading precision.Keeping your lathe in great shape is easy with regular care. First, inspect your lathe often. Look for dirt, wear, or loose parts. Clean it with a soft cloth. For threading, always check the dial for accuracy. Follow these best practices:

- Use clean lathe oil.

- Keep the threading dial aligned.

- Adjust speed to match the material.

These tips help your lathe last longer and work better.

How often should I check my lathe?

You should check your lathe at least once a month for signs of wear and dirt.

Common Mistakes to Avoid During Oil Change

Frequent errors when replacing lathe oil. Consequences of neglecting oil maintenance.Changing lathe oil can be tricky. Common mistakes pop up often. Skipping a proper cleaning of the oil reservoir can lead to dirt buildup. Not using the right type of oil can harm your machine too. Remember, neglecting regular maintenance can cause costly repairs down the line. It’s important to check the oil level regularly!

What are the most frequent errors in oil changes?

Some common errors include:

- Forgetting to clean the area before adding new oil.

- Using the wrong oil type for the lathe.

- Not checking for leaks after the change.

Frequently Asked Questions About Lathe Oil Change

Common queries related to oil types and maintenance. Expert answers and clarifications on threading dials.People often wonder about what oil to use for their lathe. It’s important to choose the right kind. Using the wrong oil can make your machine sad! Experts recommend a light machine oil that keeps everything running smoothly. Maintenance is key for a happy lathe. Regular checks can save you from headaches down the road. And about that threading dial? It helps you measure how much metal you’re taking off! Keep it clean for best results. If only changing oil was as easy as changing a light bulb!

| Type of Oil | Best For |

|---|---|

| Light Machine Oil | General use and maintenance |

| Spindle Oil | High-speed operations |

| Way Oil | For sliding surfaces |

Conclusion

In conclusion, changing the lathe oil is crucial for your metal lathe’s performance. It helps keep everything running smoothly and prolongs its life. When using the threading dial, ensure it’s properly maintained for accurate results. So, check your lathe oil regularly and don’t hesitate to learn more about lathe care. This will make your projects even better!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change And The Threading Dial For A Metal Lathe:When you change the oil in a lathe, you help it run smoothly. First, turn off the machine and unplug it. Then, open the oil drain and let the old oil out. After that, add new oil to the right level. This keeps your lathe in good shape!

Sure! Please provide the question you would like me to answer.

What Type Of Oil Is Recommended For Lubricating A Metal Lathe, And How Often Should It Be Changed?To lubricate a metal lathe, you should use a light machine oil or way oil. This oil helps keep the moving parts running smoothly. You should change the oil every six months or whenever it looks dirty. Keeping the lathe clean and well-oiled helps it last longer!

How Do You Properly Perform An Oil Change On A Metal Lathe To Ensure Optimal Performance And Longevity?To change the oil in a metal lathe, first, turn off the machine and unplug it. Then, find the oil drain plug and remove it to let old oil flow out. Next, clean the oil filter if there is one. After that, add new oil through the filling hole until it’s at the right level. Finally, replace the drain plug and check for leaks. Doing this helps your lathe run smoothly and last longer.

What Are The Common Signs That Indicate The Threading Dial On A Metal Lathe Needs Adjustment Or Maintenance?If the threading dial on a metal lathe isn’t working well, you might see some problems. First, the threads may not line up correctly. You might also notice strange noises coming from the machine. Sometimes, you won’t get smooth cuts while working. If you see these signs, it’s a good idea to adjust or check the dial.

How Can Improper Oil Levels Affect The Performance Of The Threading Dial During Metal Lathe Operations?If there isn’t enough oil in the lathe, the threading dial can get stuck. This makes it hard for you to line up the cuts properly. Too much oil can also create a mess and make it slippery. Both problems can make your work less accurate and take more time. Keeping the oil at the right level helps the threading dial work smoothly.

What Steps Should Be Taken To Clean And Maintain The Threading Dial Mechanism On A Metal Lathe?To clean the threading dial on a metal lathe, first, turn off the machine. Next, use a soft brush to remove any dirt or chips. Then, check for oil on the dial. If it’s dry, put a few drops of oil on it to keep it working smoothly. Finally, move the dial a few times to spread the oil.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Oil Change And The Threading Dial For A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you change the oil in a lathe, you help it run smoothly. First, turn off the machine and unplug it. Then, open the oil drain and let the old oil out. After that, add new oil to the right level. This keeps your lathe in good shape!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Type Of Oil Is Recommended For Lubricating A Metal Lathe, And How Often Should It Be Changed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To lubricate a metal lathe, you should use a light machine oil or way oil. This oil helps keep the moving parts running smoothly. You should change the oil every six months or whenever it looks dirty. Keeping the lathe clean and well-oiled helps it last longer!”}},{“@type”: “Question”,”name”: “How Do You Properly Perform An Oil Change On A Metal Lathe To Ensure Optimal Performance And Longevity?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To change the oil in a metal lathe, first, turn off the machine and unplug it. Then, find the oil drain plug and remove it to let old oil flow out. Next, clean the oil filter if there is one. After that, add new oil through the filling hole until it’s at the right level. Finally, replace the drain plug and check for leaks. Doing this helps your lathe run smoothly and last longer.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate The Threading Dial On A Metal Lathe Needs Adjustment Or Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the threading dial on a metal lathe isn’t working well, you might see some problems. First, the threads may not line up correctly. You might also notice strange noises coming from the machine. Sometimes, you won’t get smooth cuts while working. If you see these signs, it’s a good idea to adjust or check the dial.”}},{“@type”: “Question”,”name”: “How Can Improper Oil Levels Affect The Performance Of The Threading Dial During Metal Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If there isn’t enough oil in the lathe, the threading dial can get stuck. This makes it hard for you to line up the cuts properly. Too much oil can also create a mess and make it slippery. Both problems can make your work less accurate and take more time. Keeping the oil at the right level helps the threading dial work smoothly.”}},{“@type”: “Question”,”name”: “What Steps Should Be Taken To Clean And Maintain The Threading Dial Mechanism On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean the threading dial on a metal lathe, first, turn off the machine. Next, use a soft brush to remove any dirt or chips. Then, check for oil on the dial. If it’s dry, put a few drops of oil on it to keep it working smoothly. Finally, move the dial a few times to spread the oil.”}}]}