Have you ever watched a metal lathe in action? It’s fascinating how it turns raw metal into beautiful shapes. One key tool that makes this possible is the lathe parting tool. But not all parting tools are equal. Finding the best metal lathe parting tool can make a big difference in your projects.

Imagine you are working on a series of metal pieces. You want smooth cuts and quick results. The right parting tool can help you achieve that. So, how do you choose the best one for your lathe? And what features should you look for?

In this article, we will explore the top options available. We will help you understand what makes a lathe parting tool really stand out. You might be surprised by some of the tools we recommend. Let’s dive in and discover what can elevate your metalworking game!

Lathe Parting Tool: Best Metal Lathe For Precision Work

Lathe Parting Tool Best Metal Lathe

A lathe parting tool is vital for shaping metal accurately. This tool makes creating clean cuts seamless. Did you know that choosing the right metal lathe can save you time and effort? The best metal lathes offer durability and precision, making projects easier. It’s essential to consider materials and build quality. Look for features like adjustable cutting depths for better control. With the right lathe parting tool, your projects can achieve professional results!Understanding Lathe Parting Tools

Definition and function of parting tools in metalworking.. Types of parting tools available for metal lathes..Parting tools are special tools used in metalworking to slice off pieces from a larger workpiece. Think of them as the “cheese cutters” of the lathe world; they help separate and shape metal neatly. There are a few main types of parting tools for metal lathes. Some are straight, while others are angled for better access. Each type has its own job and style. Here’s a quick table to help you understand:

| Type of Tool | Description |

|---|---|

| Straight Parting Tool | Used for straight cuts and is the most common type. |

| Relieved Parting Tool | Has a relieved back to reduce friction during cutting. |

| Angled Parting Tool | Designed for cuts at an angle, perfect for tricky spots! |

Using the right parting tool makes a big difference. A well-made cut is like a good haircut—nobody wants a jagged line!

Key Features to Look for in a Parting Tool

Material composition and its impact on performance.. Blade width and geometry for different applications..Choosing the right parting tool can make a big difference. The material of the blade affects how well the tool cuts. A strong steel or carbide blade lasts longer and performs better. Next, blade width is important too. Thicker blades are great for deep cuts, while thinner ones are better for detailed work. Consider these features for the best results in your projects.

What should I look for in a parting tool?

Look for these key features:

- Material: Choose steel or carbide for durability.

- Blade Width: Opt for thicker blades for deep cuts and thinner ones for precision.

- Geometry: Different shapes can suit various cutting needs.

Best Lathe Parting Tools for Metal Lathes

List and description of toprated parting tools.. Pros and cons of each tool based on user feedback..Choosing the right lathe parting tools can make a huge difference in your metalworking projects. Let’s dive into some top-rated options! First up is the HSS Parting Tool. It’s loved for its sharpness and durability. Users often say it cuts like butter, but it can dull quickly if used incorrectly. Next is the Carbide Insert Tool. It lasts longer but can be a bit pricier. Don’t worry, though; you won’t need a second mortgage! Lastly, there’s the Mini Parting Tool. Perfect for smaller projects, but it lacks power for tougher cuts.

| Tool Name | Pros | Cons |

|---|---|---|

| HSS Parting Tool | Sharp, durable | Dulls quickly |

| Carbide Insert Tool | Long-lasting | Higher cost |

| Mini Parting Tool | Great for small jobs | Less power |

Remember, the best tool is the one that fits your project! Happy turning!

How to Choose the Right Parting Tool for Your Needs

Considerations based on metal type and job requirements.. Recommendations based on skill level and budget..Choosing the right parting tool is important for your metalwork projects. First, think about the metal type you will work with. Some tools work better with harder metals, while others suit softer materials. Next, consider your job requirements. What shape and size do you need? Also, match your choice to your skill level. Beginners might prefer easier tools, while experts can use more complex ones. Budget matters too. Here are some tips:

- For beginners, choose tools that are more affordable and easy to handle.

- If you’re experienced, invest in high-quality tools that can last longer.

- For hard metals, select specialized parting tools with durable edges.

- For soft metals, common tools are usually sufficient.

What factors should I consider for my parting tool?

Focus on metal type, job requirements, skill level, and budget. Each affects your choice greatly.

Maintenance Tips for Longevity of Parting Tools

Best practices for caring for and storing parting tools.. Signs that indicate a parting tool needs replacement or sharpening..Parting tools need care to last. Store them safely in a dry place. Keep them clean and avoid rust. Check for damage often. Signs of wear include dull edges or chips. If the tool scratches instead of cuts, sharpening is needed. Replace it if it breaks or cannot be sharpened effectively.

How can I tell if my parting tool needs sharpening?

Look for signs like dull edges or poor cutting performance. If the tool struggles, it’s time to sharpen or replace it!

Best practices for caring for parting tools

- Keep them clean after use.

- Store in a protective case.

- Regularly check for wear.

Common Mistakes to Avoid When Using Parting Tools

Frequent errors that can lead to tool damage or inferior results.. Tips for achieving optimal cutting performance..Using parting tools can be tricky if you make common mistakes. Many users press too hard, which can damage the tool. Others forget to keep the tool sharp, leading to rough cuts. To work best, follow these tips:

- Always use the right speed for your material.

- Keep the tool well-maintained and sharp.

- Don’t force the cut; let the tool do the work.

These steps will help you get great results and protect your tool.

What are common mistakes while using parting tools?

Forgetting to use the right speed and pressure can lead to bad cuts. Always check your tool’s condition before starting.

DIY vs. Commercial Parting Tools

Advantages and disadvantages of making your own parting tools.. Situations where purchasing a commercial tool is preferable..Making your own parting tools can be fun and cost-effective. You can use scraps and tweak them to fit your style. However, homemade tools might not always be reliable. On the other hand, commercial tools come ready to use—they’re like that friend who always has snacks on hand! But they can be pricey and sometimes overwhelm you with options.

| DIY Parting Tools | Commercial Parting Tools |

|---|---|

| Cheaper to make | Instantly ready to use |

| Customizable | High-quality steel |

| A bit trial-and-error | More expensive |

So, if you need a quick tool for a project, buying one is often best. But if you enjoy tinkering, DIY might be your jam!

Conclusion

In summary, the best lathe parting tool makes your metalworking easier and more precise. It helps you cut metal smoothly and efficiently. Always choose a tool that fits your lathe and projects. We encourage you to explore different options and read reviews. Start by trying out a few tools to see what works best for you!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools And The Best Metal Lathes:Lathe parting tools help cut pieces of metal from a bigger piece as you work. The best metal lathes are machines that spin metal to shape it. They can be used for different projects at home or in shops. When choosing a lathe, look for one that fits your needs. A good lathe can help you make cool things!

Sure! Please provide the question you’d like me to answer.

What Are The Key Features To Look For In A High-Quality Parting Tool For Metal Lathes?When you choose a parting tool for metal lathes, look for strong materials like high-speed steel. It should stay sharp for a long time. A good parting tool has a proper thickness and shape for cutting easily. Also, make sure the tool fits your lathe well. Finally, a comfortable handle helps you control the tool better.

How Do Different Materials Used In Parting Tools Affect Their Performance On A Metal Lathe?The material of a parting tool affects how well it cuts metal on a lathe. Harder materials last longer and make cleaner cuts. Softer materials might wear out quickly and create rough edges. If you use the right material for the job, it will help you finish your work better and faster.

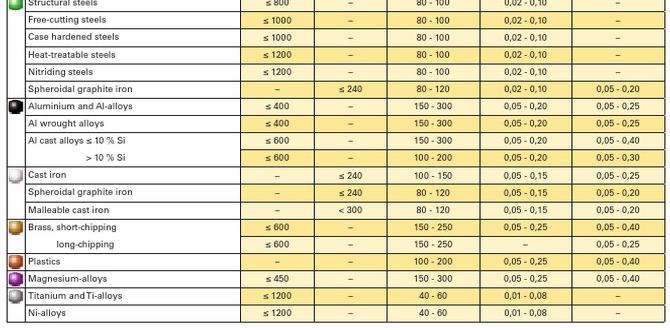

What Is The Recommended Cutting Speed And Feed Rate When Using A Parting Tool On A Metal Lathe?When using a parting tool on a metal lathe, you should use a cutting speed of about 100 to 300 feet per minute. The feed rate, or how fast you push the tool, should be around 0.005 to 0.015 inches per revolution. This helps the tool cut smoothly without breaking. Always remember to adjust based on the type of metal you’re working with!

Can You Compare The Effectiveness Of Various Parting Tool Designs, Such As Blade Style Versus Insert Type?Some parting tools have blades, and others use inserts. Blade-style tools are often strong and last a long time. Insert-type tools can be changed easily and keep cutting sharp. Both styles work well, but it depends on what you need them for. You can choose the one that fits your project best!

What Are The Best Practices For Setting Up A Metal Lathe For Parting Operations To Ensure Precision And Safety?To set up a metal lathe for parting, you should start by checking the tool’s sharpness. Make sure the parting tool is tight and secure in the holder. You also want to set the right speed for cutting metal. Look out for any loose pieces and always wear safety goggles. This helps keep you safe while making precise cuts.