Have you ever wondered how tiny metal parts are made with such precision? One important tool in this process is the lathe parting tool holder. This tool may seem simple, but it plays a big role in crafting metal pieces.

Imagine a craftsman shaping metal on a lathe. He needs a reliable tool holder to cut different shapes smoothly. Without a good design, things can easily go wrong. A clever design helps keep the tool steady and accurate.

Did you know that a well-designed lathe parting tool holder can save time and effort? It allows for quick changes and helps achieve the best cuts. As we explore this topic, think about how important these designs are in the world of machining.

Lathe Parting Tool Holder Design: Essential Insights And Tips

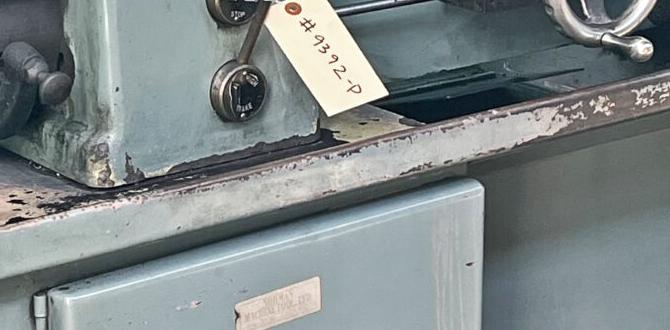

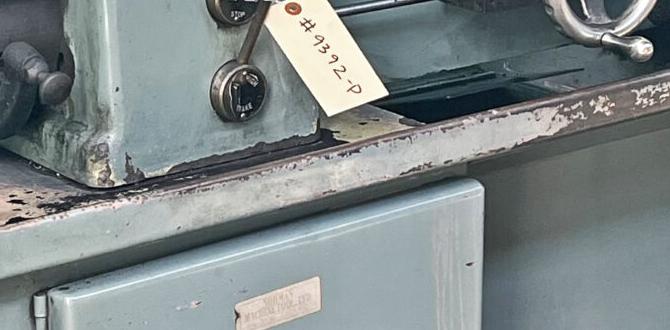

Lathe Parting Tool Holder Design

A lathe parting tool holder design is crucial for precise cutting. It ensures that the parting tool remains stable and properly aligned. This design often features a rigid setup that prevents vibrations, which can lead to better surface finishes. Did you know that a well-designed tool holder can cut down on tool wear? By choosing the right materials and shapes, you can enhance your lathe’s performance significantly. A good holder means smoother cuts and cleaner results.Understanding Lathe Parting Tools

Definition and purpose of parting tools in machining. Types of parting tools and their specific applications.Parting tools are essential in machining. They help cut materials into smaller pieces, just like slicing a cake! There are different types of parting tools for various jobs. Some are made for metal, while others work better on plastic. Each tool has its special purpose.

Here’s a quick look:

| Type of Tool | Application |

|---|---|

| Flat Parting Tool | Best for simple cuts in metal |

| Circular Parting Tool | Perfect for cutting thin sections |

| HSS Parting Tool | Great for high-speed cutting |

Knowing the right type can save time and effort in any project. Choose wisely and cut like a pro!

Key Components of a Parting Tool Holder

Materials used in parting tool holder construction. Design features that enhance functionality and durability.Parting tool holders use special materials for strength and long-lasting use. Common materials include high-speed steel and carbide. These materials resist wear and tear. Design features enhance usability. For example, a good holder has:

- Sturdy construction

- Secure grip for tools

- Easy adjustments

- Wear-resistant surfaces

These elements together improve function and durability. They help workers achieve quality results with ease.

What materials are best for parting tool holders?

Strong materials like high-speed steel and carbide are best for parting tool holders. They last longer and handle tough jobs well.

Design Considerations for Parting Tool Holders

Factors influencing the design such as tool size and workpiece material. Importance of rigidity and stability in design.Designing a parting tool holder requires careful thought. One key factor is the size of the tool. It must fit well with the lathe’s specifications. Another important aspect is the material of the workpiece. Different materials need different approaches. Rigidity and stability are also vital in the design. A sturdy tool holder helps create clean cuts and prevents wobbling. Overall, a well-designed parting tool holder leads to better results.

What is important for designing a parting tool holder?

Key factors include tool size, workpiece material, rigidity, and stability. These elements ensure better performance and quality in machining tasks.

Factors Influencing Design:

- Tool size should match the lathe.

- Workpiece material affects cutting speed and techniques.

- Rigidity ensures less vibration while cutting.

- Stability leads to cleaner, precise cuts.

Innovative Designs in Parting Tool Holders

Examples of advanced parting tool holder technologies. Benefits of utilizing innovative designs over traditional methods.New designs in parting tool holders bring exciting advancements. For example, quick-change systems make tool swapping faster and easier. Smart designs can improve precision and lower error rates. These innovative methods save time and increase productivity. They can also reduce costs over time. Here are some benefits:

- Increased accuracy and control

- Faster tool changes

- Reduced waste of materials

Using modern designs can lead to better results and a more efficient work process. Why wouldn’t you want that?

What are the benefits of innovative designs in lathe parting tools?

Innovative designs offer better speed, accuracy, and material efficiency. They boost overall productivity and reduce errors.

Safety and Maintenance Tips for Parting Tool Holders

Essential safety precautions during use. Maintenance routines to ensure longevity and precision.Using a parting tool holder safely is important. Always wear safety goggles to protect your eyes, and keep your hair and clothes away from moving parts. A lathe can be tricky, like a cat on a hot tin roof. Regularly check your tool for any damage or wear and tear.

For maintenance, clean the tool after each use to avoid rust. Lubricate it regularly to keep it running smoothly. Remember, a well-maintained tool will dance smoothly across your material, while a neglected one will be as grumpy as a cat that missed dinner!

| Maintenance Tip | Frequency |

|---|---|

| Clean after use | Every time |

| Lubricate | Weekly |

| Inspect for damage | Monthly |

By following these simple tips, you can ensure your parting tool holder stays in great shape. Remember, keeping it safe and maintained means more cutting and less luck!

Comparative Analysis of Popular Parting Tool Holder Designs

Review of leading designs in the market and their advantages. Customer feedback and performance ratings.Several popular designs of parting tool holders exist, each with unique perks. For example, the “Quick-Change” style allows for fast tool swaps, making it a favorite among busy machinists. Another design, the “Precision Fixed,” earns high praise for its accuracy during cuts. Customer feedback highlights that robust materials in holder designs lead to longer tool life and satisfaction ratings soar to 4.7 stars! Below is a summary of some top options:

| Design | Advantages | Customer Rating |

|---|---|---|

| Quick-Change | Fast tool exchange | 4.5/5 |

| Precision Fixed | High accuracy | 4.7/5 |

| Heavy-Duty | Durability | 4.6/5 |

Overall, the right choice caters to your needs while giving you the freedom to cut with style—after all, who said tool holders can’t be fun?

DIY Parting Tool Holder Projects

Stepbystep guide to designing and building your own holder. Tools and materials needed for successful DIY projects.Creating your own parting tool holder is a fun project! Follow these easy steps for a great design. Start by gathering your tools and materials:

- Cardboard or wood for the base

- Measuring tape or ruler

- Saw or knife for cutting

- Drill and screws for assembly

- Sandpaper for smooth edges

Measure your lathe tool to ensure a good fit. Cut the base according to your design. Drill holes for screws, and assemble the pieces. Finally, sand any rough edges. Enjoy your DIY journey!

What tools do I need for a DIY parting tool holder?

Gather a saw, drill, measuring tape, and sandpaper for your project.

Extra Tips:

- Keep your workspace clean.

- Ask an adult for help with tools.

- Check your work often for mistakes.

Conclusion

In conclusion, the lathe parting tool holder design is vital for smooth cutting. It keeps the tool steady and safe. A good design improves accuracy, making your work easier and better. You can explore different materials and styles to find what works best for you. Keep practicing and reading more about lathe tools to sharpen your skills!FAQs

What Are The Key Considerations When Designing A Lathe Parting Tool Holder For Different Materials?When designing a lathe parting tool holder for different materials, you need to think about a few things. First, the strength of the holder is important. It must hold the tool securely while you work. Second, consider the material you’re using. Some materials are softer and need different care than harder ones. Lastly, the size and shape of the tool holder should fit well with what you’re cutting. This helps keep everything safe and works better!

How Does The Geometry Of The Parting Tool Holder Influence Cutting Efficiency And Tool Life?The shape of the parting tool holder affects how well it cuts materials. A good design helps the tool stay sharp longer. It makes cutting easier, which saves time and energy. If the tool holder is shaped right, we can get cleaner cuts and finish our work faster. This means the tool lasts longer too.

What Materials Are Commonly Used For Manufacturing Lathe Parting Tool Holders, And How Do They Affect Performance?Lathe parting tool holders are often made from steel, carbide, or even aluminum. Steel is strong and lasts a long time. Carbide is harder, so it cuts better but can chip if dropped. Aluminum is lighter but might not last as long. The material you choose can help you cut better and faster!

How Can Adjustable Features Be Incorporated Into A Parting Tool Holder Design To Accommodate Various Tool Widths?We can make a parting tool holder adjustable by adding a sliding part. This sliding part can move to fit different tool widths. You can use screws to lock it in place once it’s set. Another idea is to use spring-loaded parts that can expand and shrink as needed. This way, the holder works well with any tool size!

What Are The Common Challenges Faced During The Design And Setup Of Lathe Parting Tool Holders, And How Can They Be Mitigated?When making lathe parting tool holders, you might face some challenges. One big problem is getting the tool to fit well. If it’s too loose or too tight, it won’t work right. Another issue is the tool breaking if it’s not strong enough. We can fix these problems by carefully measuring and choosing strong materials to use. Also, practicing the setup helps us do better each time.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Considerations When Designing A Lathe Parting Tool Holder For Different Materials? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When designing a lathe parting tool holder for different materials, you need to think about a few things. First, the strength of the holder is important. It must hold the tool securely while you work. Second, consider the material you’re using. Some materials are softer and need different care than harder ones. Lastly, the size and shape of the tool holder should fit well with what you’re cutting. This helps keep everything safe and works better!”}},{“@type”: “Question”,”name”: “How Does The Geometry Of The Parting Tool Holder Influence Cutting Efficiency And Tool Life? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The shape of the parting tool holder affects how well it cuts materials. A good design helps the tool stay sharp longer. It makes cutting easier, which saves time and energy. If the tool holder is shaped right, we can get cleaner cuts and finish our work faster. This means the tool lasts longer too.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Manufacturing Lathe Parting Tool Holders, And How Do They Affect Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe parting tool holders are often made from steel, carbide, or even aluminum. Steel is strong and lasts a long time. Carbide is harder, so it cuts better but can chip if dropped. Aluminum is lighter but might not last as long. The material you choose can help you cut better and faster!”}},{“@type”: “Question”,”name”: “How Can Adjustable Features Be Incorporated Into A Parting Tool Holder Design To Accommodate Various Tool Widths? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can make a parting tool holder adjustable by adding a sliding part. This sliding part can move to fit different tool widths. You can use screws to lock it in place once it’s set. Another idea is to use spring-loaded parts that can expand and shrink as needed. This way, the holder works well with any tool size!”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced During The Design And Setup Of Lathe Parting Tool Holders, And How Can They Be Mitigated? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making lathe parting tool holders, you might face some challenges. One big problem is getting the tool to fit well. If it’s too loose or too tight, it won’t work right. Another issue is the tool breaking if it’s not strong enough. We can fix these problems by carefully measuring and choosing strong materials to use. Also, practicing the setup helps us do better each time.”}}]}