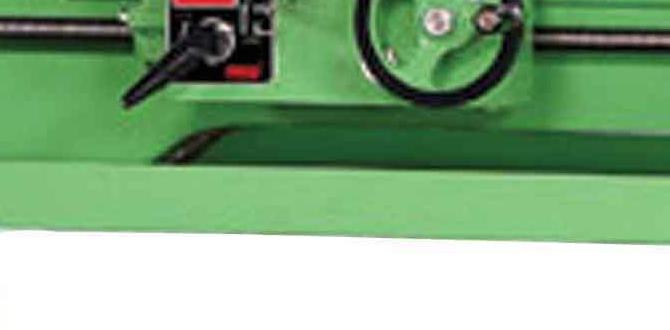

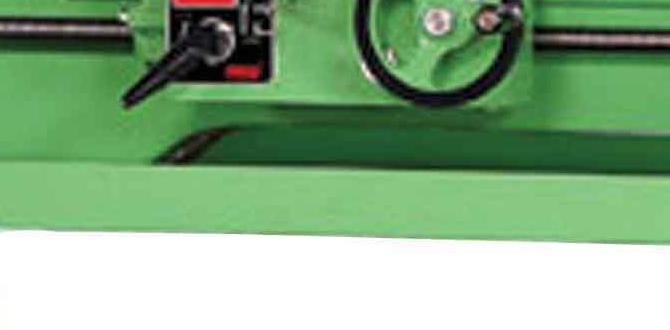

Have you ever watched a metal lathe in action? It’s pretty exciting! One key part of this machine is the lathe parting tool, which helps cut materials smoothly and precisely. Imagine shaping a block of metal into a perfect piece. The metal lathe carriage supports the tool, making the process easier.

But what exactly makes this tool so special? The lathe parting tool works like a sharp knife, slicing through metal as the lathe spins. The carriage moves it back and forth, allowing for accurate cuts. This tool is essential for anyone looking to create metal parts. Whether you’re a hobbyist or a professional, understanding this helps you work better.

Did you know that the design of these tools hasn’t changed much over the years? They’ve been used for centuries! This shows how important they are in metalworking. As we delve deeper, you’ll discover tips and tricks to using the lathe parting tool effectively. Ready to learn more?

Essential Lathe Parting Tool For Metal Lathe Carriage Use

Lathe Parting Tool Metal Lathe Carriage

The lathe parting tool is essential for any metal lathe user. It helps cut and separate materials effectively. Imagine a sculptor carefully chiseling away at stone. That’s how a lathe parting tool works! By attaching it to the carriage, you easily move it across your workpiece. This tool makes clean, precise cuts, which is crucial for shaping metal. Did you know that these tools come in various shapes? Choosing the right one can make all the difference in your projects!Understanding Lathe Parting Tools

Definition and function of lathe parting tools. Materials commonly used in manufacturing parting tools.Lathe parting tools are like the superheroes of the metalworking world. They help cut materials into neat pieces. Imagine trying to slice cake with a butter knife – not so easy! Now, there are usually made from tough materials like high-speed steel or carbide. These materials can withstand high temperatures and stay sharp for longer. Let’s not forget about the proper angles! They help make clean cuts, as precise as a cat stalking its prey. Here’s a quick look at the materials:

| Material | Benefits |

|---|---|

| High-Speed Steel | Strong and lasts long, perfect for many jobs. |

| Carbide | Super tough, great for hard metals! |

So, next time you see a lathe parting tool, remember it’s not just a tool. It’s a cutting champion!

The Role of Parting Tools in Metal Lathes

Importance of parting tools in metalworking. How parting tools enhance the efficiency of metal lathes.Parting tools play a key role in metalworking. They help slice through materials with precision, saving time and effort. Think of them as the superhero of the lathe world, swooping in to finish jobs quickly. With these tools, metal lathes work more efficiently, allowing for smoother operation and less material waste. This means more finished products and fewer headaches for the machinist. So, grab your parting tool and let’s get cutting!

| Reason | Benefit |

|---|---|

| Precise Cuts | Better quality products |

| Faster Operations | More time for snacks! |

| Less Waste | More savings for toys! |

Choosing the Right Parting Tool for Your Metal Lathe Carriage

Factors to consider when selecting a parting tool. Comparison of different types of parting tools available.Choosing the right parting tool for your metal lathe carriage is like picking a superhero for your workshop. First, consider the material you’ll be working with: is it steel or aluminum? Different tools shine on different metals. Next, look at the tool’s width and length—too wide may create problems, and too narrow might not cut it! Lastly, think about the design. Straight tools, angled ones, and even those with chip control options are out there. Each has its own superpower.

| Type of Parting Tool | Best For | Key Feature |

|---|---|---|

| Standard Tool | General use | Easy handling |

| Grooving Tool | Creating grooves | Precise cuts |

| Heavy-Duty Tool | Thicker materials | Durability |

Remember, picking the right parting tool can save you time and headaches. You don’t want to be fighting with your lathe like it’s a bull at a rodeo!

Proper Techniques for Using Parting Tools

Stepbystep guide on how to use parting tools effectively. Common mistakes to avoid during the parting process.Using parting tools correctly can make your metalworking projects smooth like butter! First, make sure your tool is securely positioned. Next, use a slow feed rate and a steady hand. Don’t rush, or you might end up with a mess! Avoid common mistakes like angled cuts or too much pressure – that’s how you create a *not-so-fun* disaster. Remember, safety first and fun second!

| Common Mistakes | How to Avoid |

|---|---|

| Cutting too quickly | Use a steady, slow feed rate |

| Not securing the tool | Check your tool’s position before starting |

| Using too much pressure | Let the tool do the work, not your muscles! |

Maintaining and Caring for Your Parting Tools

Best practices for tool maintenance and longevity. Tips on sharpening and storing parting tools.To keep your parting tools in great shape, regular maintenance is key! First, always clean them after use. A quick wipe can prevent rust and make your tools shine like stars! Next, sharpening is essential. Use a fine whetstone for a nice edge. Remember, a sharp tool is a happy tool—just like you after a good meal! Always store them safely, perhaps in a cozy box, away from dampness. Lastly, keep an eye out for wear and tear; replacing a worn part is cheaper than a trip to the tool graveyard!

| Best Practices | Tips |

|---|---|

| Clean tools after each use | Use a fine whetstone for sharpening |

| Store in a dry place | Replace worn parts on time |

Common Applications of Parting Tools in Metalworking

Various projects where parting tools are essential. Examples of industries that rely heavily on parting tools.Parting tools are key in many metalworking tasks. They help shape and cut materials efficiently. Different projects benefit from these tools, making them important in various settings. Here are some industries that rely heavily on parting tools:

- Aerospace: Used to create precise parts for aircraft.

- Automotive: Essential for making car components.

- Manufacturing: Important for mass-producing metal products.

Parting tools help save time and improve accuracy, making them vital in these industries.

Why are parting tools popular in metalworking?

Parting tools are popular because they allow for quick and accurate cuts, reducing waste and speeding up production time.

Troubleshooting Common Issues with Parting Tools

Identifying and resolving common problems encountered. Tips for improving results when using parting tools.When using parting tools, problems can happen. It’s good to know how to fix them. Here are some common issues and tips:

- **Tool binding:** This happens if the tool is not set correctly. Adjust the tool height for better cutting.

- **Rough cuts:** A dull tool makes jagged cuts. Make sure to sharpen your tool regularly.

- **Chatter:** This is a vibrating sound. Check to ensure the tool is secure and the feed rate is right.

By being aware of these factors, you can improve your results with lathe parting tool metal lathe carriage. Happy turning!

What should I check if my parting tool is not cutting well?

First, ensure the tool is sharp. A dull tool won’t cut smoothly. Next, check its position. The tool must sit at the right height. Finally, adjust the feed rate for a better finish.

Conclusion

In summary, a lathe parting tool is essential for cutting metal on a lathe. It helps create clean edges and shapes. The metal lathe carriage moves the tool smoothly for accuracy. Understanding these tools can improve your skills. So, practice using a lathe and explore more materials on lathe techniques. You’ll discover exciting projects to try next!FAQs

Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Carriages:Sure! A lathe parting tool is a sharp tool used to cut off pieces of metal while it spins on a machine called a lathe. The metal lathe carriage helps move the parting tool across the metal to cut it. You can adjust the carriage to make different cuts. This makes it easier to shape the metal just how you want it. Using these tools lets us create cool shapes and parts!

Sure! Please share the question you want me to answer.

What Is The Primary Function Of A Parting Tool In A Metal Lathe Operation?A parting tool helps us cut off pieces of metal from a shape we’re making on a lathe. It looks like a flat piece of metal. When we press it into the spinning metal, it slices through. This way, we can create smaller parts or finish our project neatly. It’s an important tool for making sure everything is just right!

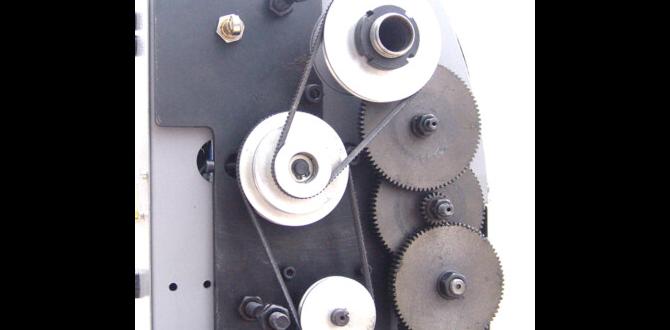

How Does The Design Of The Carriage Influence The Effectiveness Of Parting Operations On A Lathe?The carriage of a lathe helps hold and move the tool. A good design keeps the tool steady while working. This makes cutting easier and smoother. If the carriage is wobbly, it can create rough cuts. So, a well-designed carriage helps us make better parts.

What Materials Are Commonly Used For Manufacturing Lathe Parting Tools, And How Do They Affect Performance?Lathe parting tools are often made from high-speed steel (HSS) or carbide. High-speed steel is tough and can handle heat well. Carbide is very hard and stays sharp longer. These materials help the tools cut better and last longer when we use them.

How Can A User Adjust The Lathe Carriage To Ensure Accurate And Clean Parting Cuts?To make sure your parting cuts are clean, you need to adjust the lathe carriage. First, check that the tool is sharp. Next, move the carriage to the right spot for your cut. You can tighten screws to hold it steady. Finally, always check your setup before starting to cut. This way, you’ll make nice, clean parts!

What Safety Precautions Should Be Taken When Using A Parting Tool On A Metal Lathe?When using a parting tool on a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and remove loose clothing. Make sure your hands stay away from the moving parts. Check that all tools are secure before starting. Finally, do not touch the tool or workpiece while it’s spinning.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Carriages:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe parting tool is a sharp tool used to cut off pieces of metal while it spins on a machine called a lathe. The metal lathe carriage helps move the parting tool across the metal to cut it. You can adjust the carriage to make different cuts. This makes it easier to shape the metal just how you want it. Using these tools lets us create cool shapes and parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Parting Tool In A Metal Lathe Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A parting tool helps us cut off pieces of metal from a shape we’re making on a lathe. It looks like a flat piece of metal. When we press it into the spinning metal, it slices through. This way, we can create smaller parts or finish our project neatly. It’s an important tool for making sure everything is just right!”}},{“@type”: “Question”,”name”: “How Does The Design Of The Carriage Influence The Effectiveness Of Parting Operations On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The carriage of a lathe helps hold and move the tool. A good design keeps the tool steady while working. This makes cutting easier and smoother. If the carriage is wobbly, it can create rough cuts. So, a well-designed carriage helps us make better parts.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Manufacturing Lathe Parting Tools, And How Do They Affect Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe parting tools are often made from high-speed steel (HSS) or carbide. High-speed steel is tough and can handle heat well. Carbide is very hard and stays sharp longer. These materials help the tools cut better and last longer when we use them.”}},{“@type”: “Question”,”name”: “How Can A User Adjust The Lathe Carriage To Ensure Accurate And Clean Parting Cuts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure your parting cuts are clean, you need to adjust the lathe carriage. First, check that the tool is sharp. Next, move the carriage to the right spot for your cut. You can tighten screws to hold it steady. Finally, always check your setup before starting to cut. This way, you’ll make nice, clean parts!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using A Parting Tool On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a parting tool on a metal lathe, always wear safety goggles to protect your eyes. Keep your hair tied back and remove loose clothing. Make sure your hands stay away from the moving parts. Check that all tools are secure before starting. Finally, do not touch the tool or workpiece while it’s spinning.”}}]}