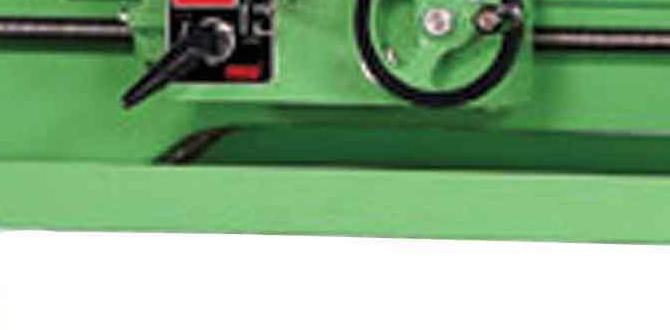

Have you ever wondered how metal parts are made? One important tool in this process is the lathe parting tool. It plays a key role in shaping materials during metalworking. Picture a giant machine that spins metal, cutting it into precise shapes. That’s what a lathe does!

Many people might not know how a drive system powers these machines. The drive system acts like the engine of a car. It keeps everything running smoothly while you work. Without it, the lathe can’t function properly.

Here’s a fun fact to think about: did you know that the lathe is one of the oldest tools in history? People have used it for thousands of years to create amazing things. Whether you are a beginner or a pro, understanding the lathe parting tool and its drive system is essential. Are you ready to dive deeper into this fascinating topic?

Lathe Parting Tool For Metal Lathe Drive System Explained

Insights on Lathe Parting Tools and Metal Lathe Drive Systems

Lathe parting tools are essential for cutting materials in metalworking. These tools help create clean edges on metal pieces. A reliable drive system powers a metal lathe, making sure the cutting is smooth and efficient. Have you ever seen a metal piece transformed into a masterpiece? The right combination of tool and drive enhances precision. It’s fascinating how these simple tools can turn raw metal into art! Understanding their function not only boosts skills but also enriches the crafting experience.Understanding Lathe Parting Tools

Definition and function of parting tools in metalworking. Types of parting tools and their applications.Parting tools are special cutting tools used in metalworking. They make narrow cuts to separate materials. Think of them like scissors for metal! There are different types of parting tools, each serving a unique purpose:

- Regular parting tools: Best for making straight cuts.

- Grooving tools: Used for carving grooves in metal.

- Form tools: Designed for cutting specific shapes.

These tools help workers create precise parts quickly, making them very important in metal lathes.

What are the different types of parting tools?

Different types include regular tools, grooving tools, and form tools. Each type has its own job, helping in various metal shaping tasks.

Importance of Parting Tools in Metal Lathe Drive Systems

Role of parting tools in achieving precision and efficiency. Impact on overall productivity in metal lathe operations.Parting tools are like the superheroes of metal lathe drive systems. They save the day by cutting materials precisely, making each project look sharp—pun intended! With a good parting tool, you can achieve high precision in your work, which means fewer mistakes and less wasted time. This boosts overall productivity and helps you finish projects faster. Faster projects mean more time for snacks and fun! So, in the world of metal lathe operations, parting tools are the unsung champions that keep everything running smoothly.

| Benefit | Description |

|---|---|

| Precision | Ensures accurate cuts for better results. |

| Efficiency | Speeds up the process, saving time. |

| Productivity | Increases output, allowing more projects. |

Specifications of Lathe Parting Tools

Material composition and hardness levels. Sizing and geometry considerations for optimal performance.Lathe parting tools are made of strong materials. Common choices are high-speed steel and carbide. These materials ensure sharpness and durability. Hardness levels of tools range from 55 to 65 HRC. This hardness helps them cut through metal easily.

Size and shape matter too. The width of the cutting edge should match the job. A typical width is 3 to 5 mm. The geometry affects how well the tool works. This makes sure it performs its best.

What are the specifications of lathe parting tools?

The key specifications include:

- Material: High-speed steel or carbide

- Hardness: 55 to 65 HRC

- Width: 3 to 5 mm

Choosing the Right Parting Tool for Your Metal Lathe

Factors to consider: material, size, and type of metal being worked on. Recommendations for different applications and lathe configurations.Finding the right parting tool for your metal lathe is like picking the perfect pizza topping—everyone has their favorite! First, consider the material of your tool. High-speed steel is good for soft metals, but carbide wins for harder materials. Next, think about the size of your lathe. Smaller lathes need smaller tools, while bigger machines can handle more specialized cutting edges. Lastly, pay attention to the type of metal you are working with. Each metal loves a different kind of tool! Below is a handy table comparing tool types for various applications:

| Material Type | Tool Recommendation |

|---|---|

| Aluminum | High-speed steel |

| Steel | Cobalt |

| Irritating alloys | Carbide |

Choose wisely, because a good parting tool can mean the difference between a smooth finish and a big mess! Remember, even your lathe deserves a good partner.

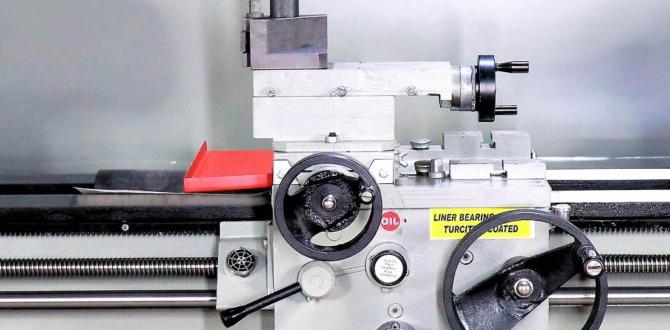

How to Properly Use a Parting Tool in a Metal Lathe

Stepbystep guide on setup and usage. Common mistakes to avoid during use.Using a parting tool in a metal lathe is simple when you follow the right steps. First, set up the lathe and ensure the tool is sharp. Next, adjust the speed for metal working. Finally, grasp the parting tool firmly and cut smoothly. Watch out for common mistakes like cutting too fast or pushing too hard. These can lead to bad cuts or tool damage. Remember, steady hands make better cuts!

What should I avoid when using a parting tool?

Avoid these common mistakes:

- Cutting too quickly.

- Pushing the tool too hard.

- Not keeping the tool sharp.

- Incorrect tool height.

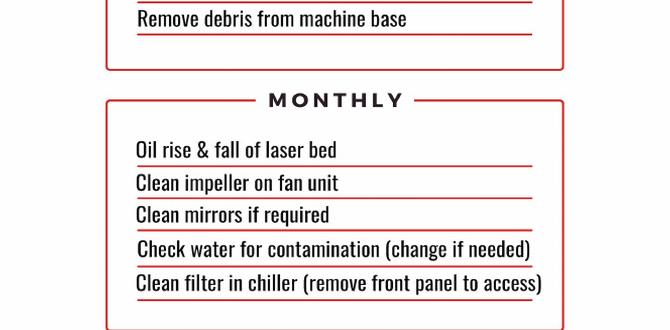

Maintenance and Care for Lathe Parting Tools

Best practices for tool cleaning and maintenance. Tips for prolonging the life of your parting tools.Keeping your tools clean is key to making them last. Regular cleaning prevents rust and keeps them sharp. Here are some best practices:

- Wipe down tools after each use.

- Use a soft brush or cloth for dirt.

- Apply a light oil to prevent rust.

To prolong the life of your parting tools, follow these tips:

- Store them in a dry place.

- Avoid dropping or hitting them.

- Sharpen blades regularly to maintain performance.

These steps help ensure your lathe parting tools work well and last long.

How often should I clean my lathe parting tools?

Clean your tools after every use to keep them in good shape and ready for your next project. Regular care makes a big difference!

Comparing Parting Tools with Other Cutting Methods

Advantages and disadvantages of parting tools versus turning and grooving. Situations where parting tools excel over other techniques.Parting tools cut through metal like butter, slicing off pieces smoothly. They shine when working with thicker materials where turning and grooving might struggle. Think of them as the superheroes of the workshop, saving the day with their precision! However, they can be a bit picky, sometimes not handling softer metals well. So, if you want to split metal without starting a wrestling match, parting tools are your trusty sidekicks.

| Tool Type | Advantages | Disadvantages |

|---|---|---|

| Parting Tools | Great for thick materials | Picky with soft metals |

| Turning | Good for shaping | Less effective for thick cutting |

| Grooving | Excellent for creating grooves | May slow down the cutting process |

Resources for Further Learning and Improvement

Recommended books, websites, and forums for metalworking enthusiasts. Online courses and workshops focusing on lathe operation and tool usage.Learning about metalworking can be exciting and fun! There are many resources that can help you improve. Consider checking out these materials:

- Books like “Machining Fundamentals” and “The Complete Manual of Wood Bending” for basics and tips.

- Websites such as Metalworking.com for detailed guides.

- Forums where enthusiasts share advice and experiences, like Practical Machinist.

- Online courses on platforms like Udemy focusing on lathe operation.

- Workshops in local maker spaces where you can practice with guidance from experts.

These resources will support your journey in mastering the lathe parting tool and metal lathe drive system. Happy learning!

What are some good places to learn about lathe tools?

You can find excellent materials on platforms such as Coursera and in your local library. Websites like Instructables offer free projects too!

Conclusion

In summary, a lathe parting tool helps shape metal effectively. Understanding your metal lathe drive system is crucial for smooth operation. You can create precise cuts with the right tools and knowledge. We encourage you to explore more about lathe tools and practice using them. This hands-on experience will boost your skills and confidence in metalworking.FAQs

Sure! Here Are Five Related Questions On The Topic Of A Lathe Parting Tool And Metal Lathe Drive Systems:A lathe parting tool is a sharp tool used to cut metal pieces. When we use a lathe, it spins the metal, and the parting tool helps slice it off. Metal lathe drive systems make the lathe turn. This way, we can create shapes from the metal. It’s like using a pencil to cut a piece of paper!

Sure! I’d be happy to help you with that. Just let me know what question you have in mind!

What Are The Key Design Features Of A Parting Tool Used In A Metal Lathe, And How Do They Affect Cutting Performance?A parting tool has a sharp edge and a flat shape. This helps it cut through metal easily. The tool is usually thin, which allows it to reach tight spaces. When you use it, it creates a clean cut. A good design helps you cut faster and makes the metal pieces smoother.

How Does The Drive System Of A Metal Lathe Influence The Efficiency And Precision Of Parting Operations?The drive system in a metal lathe helps control how fast and steady the cutting tool moves. A good drive system means the tool cuts smoothly, which makes parts fit better. If the drive system is strong, it can cut through metal easily, saving us time. This way, we can make more parts quickly and accurately.

What Materials Are Commonly Used For Manufacturing Lathe Parting Tools, And How Do Their Properties Impact Tool Longevity?Lathe parting tools are often made from high-speed steel or carbide. High-speed steel is strong and works well with metal. Carbide is even harder, so it lasts longer and cuts better. The tougher the material, the longer the tool will last before it needs to be replaced.

How Can You Adjust The Speed And Feed Rates In A Metal Lathe When Using A Parting Tool To Achieve Optimal Results?To get the best cuts with a parting tool on a metal lathe, you need to adjust the speed and feed rates. First, set the speed low to start, so the tool doesn’t get too hot. Then, you can slowly increase the speed if things are going well. Next, adjust the feed rate, which means how fast the tool moves. A slow feed helps make a clean cut, while a faster one might break the tool. Always listen to the machine; it will help you know if you need to change anything.

What Are Some Common Issues Encountered When Parting On A Lathe, And How Can They Be Mitigated Through Tooling Or Drive System Adjustments?When you part on a lathe, you might face problems like the tool breaking or the piece wobbling. To fix these issues, you can use a sharper tool or slow down the lathe speed. Tightening the piece in the chuck can also help it stay steady. Always make sure to check the setup before starting!