Have you ever watched a metal lathe in action? It’s fascinating! A lathe parting tool plays a key role in this process. This essential gear helps you cut metal smoothly and precisely.

Imagine you want to create a perfect metal part for your project. You need the right tools to get the job done. That’s where the lathe parting tool comes in. It makes sharp cuts without ruining the piece you’re working on.

Did you know that using the right gear can save you time and effort? A good parting tool can make even the most challenging tasks feel easy. So, why not explore the various options available?

In this article, we’ll dive deeper into the world of metal lathe gear and the importance of parting tools. You’ll learn tips that can help you work smarter, not harder!

Lathe Parting Tool: Essential Metal Lathe Gear Explained

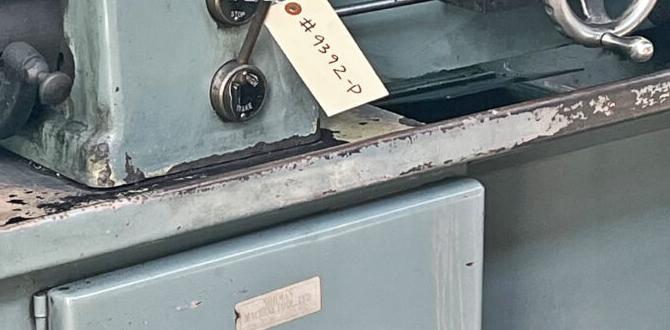

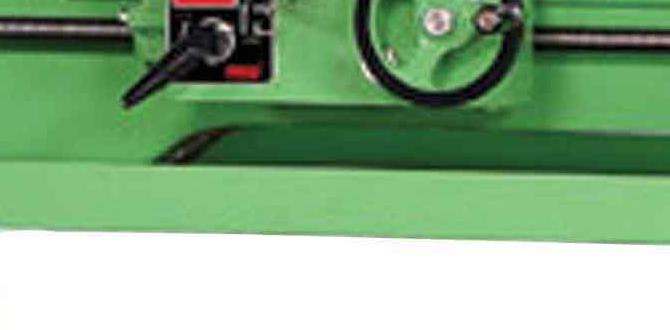

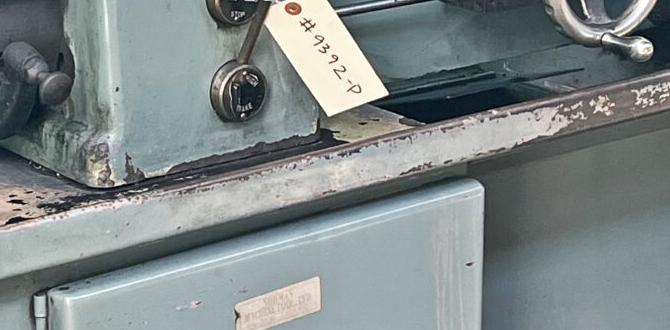

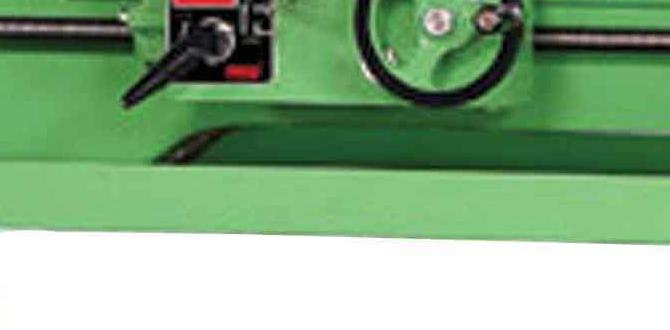

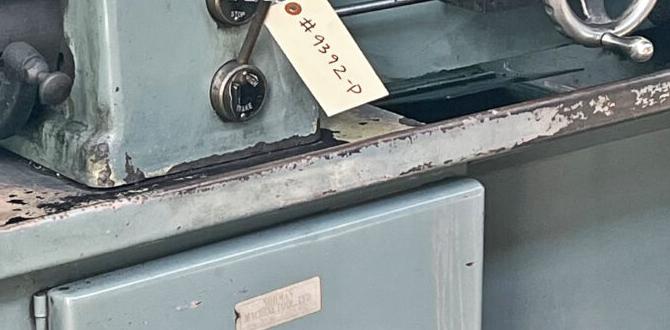

Lathe Parting Tool Metal Lathe Gear

Have you ever wondered how metal parts are made? A lathe parting tool is critical in shaping metal on a lathe. It cuts through the metal, creating neat edges. This simple tool can help you create designs for different projects. Many people find that the right gear can improve their work. By using a lathe parting tool, you can make your projects easier and more enjoyable. Did you know that a finely crafted tool can make all the difference in quality? Explore the world of metal lathing and discover its creative possibilities!What is a Lathe Parting Tool?

Definition and purpose of a parting tool in metalworking. Key features and design aspects of lathe parting tools.A lathe parting tool is a special tool in metalworking used to cut off a section of material. It’s like a magician’s wand but for metal! The main job of this tool is to create a clean break when slicing through metal, making it essential for shaping jobs. Key features include a sharp, narrow blade designed to prevent dragging, allowing for precise cuts. It often has a sturdy handle, ensuring that users can operate it without turning into a human pretzel!

| Feature | Description |

|---|---|

| Blade Shape | Narrow and sharp for precise cuts |

| Material | High-speed steel for durability |

| Handle | Ergonomic for a comfortable grip |

Choosing the Right Parting Tool for Metal Lathe Gears

Criteria for selecting the best parting tool for specific gear projects. Material compatibility and cutting properties of various tools.Selecting a parting tool for metal lathe gears is important for success in your projects. Here are some criteria to consider:

- Material Compatibility: Ensure the tool matches your gear material, like steel or aluminum.

- Cutting Properties: Choose tools with good sharpness and durability to make clean cuts.

- Size and Shape: Pick a tool that fits well within your lathe for better control.

Taking time to choose the right tool will make your gear-making easier.

What should I consider when buying a parting tool?

Look for tools made of high-speed steel or carbide. These materials last longer and cut better. Always check the manufacturer’s guide for specific projects!

Techniques for Using a Lathe Parting Tool Effectively

Stepbystep guide on proper setup and positioning. Tips for maintaining optimal cutting speed and pressure.Using a lathe parting tool can be fun and simple with the right steps! First, set up your lathe by adjusting the tool holder. Make sure the tool is sharp and properly aligned. Next, find a comfortable position. Stand steady, like a flamingo on one leg—without the wobble! Keep an eye on the cutting speed. Too fast? You might end up with more shavings than parts. Too slow? It’ll take forever!

| Speed (RPM) | Pressure (lbs) | Material |

|---|---|---|

| 500-1000 | 10-20 | Aluminum |

| 300-600 | 20-30 | Steel |

Finding that sweet spot between speed and pressure keeps your tool happy! If it is getting too hot, take a break. Everyone needs a coffee break, right? With these tips, you’ll be parting metal like a pro in no time!

Maintenance and Care for Lathe Parting Tools

Recommended cleaning and storage techniques. Importance of sharpening and tool upkeep for longevity.Taking care of your lathe parting tools keeps them sharp and happy! Regularly clean your tools with a soft cloth and some soapy water—think of it as a spa day for metal! For storage, use a cool, dry place and keep them in a protective case. Sharpening is key too; dull tools are like trying to cut butter with a spoon. Regular maintenance can double your tool’s life—now that’s a deal!

| Action | Frequency |

|---|---|

| Clean | After each use |

| Sharpen | Every few projects |

| Store | Always after use |

Real-World Applications of Parting Tools in Gear Production

Examples of projects where parting tools are used effectively. Case studies of successful gear manufacturing processes.Parting tools play a big role in making gears for various projects. For example, in the automotive industry, these tools help create precise gear shapes for engines. Parting tools are also used in watches, where tiny gears are crucial. Here are some successful projects:

- Automotive Gear Systems: Ensures high performance.

- Watch Manufacturing: Delivers accuracy in small designs.

Success in gear production often depends on the correct use of lathe parting tools. These tools help cut materials easily and accurately, boosting production efficiency.

What are common projects using parting tools?

Common projects include making automotive components and precision parts for watches. These projects highlight the importance of parting tools in achieving high-quality gear production.

Conclusion

In summary, a lathe parting tool is important for cutting metal on a lathe. It helps create precise shapes and clean edges. You can use it to make gears or other metal parts easily. If you want to learn more, explore videos or tutorials online. Practice using a lathe, and soon you’ll master your skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools For Metal Lathes And Gears:Lathe parting tools help us cut metal into smaller pieces. We use them on machines called metal lathes. These tools can make precise cuts for making gears or other shapes. They work by slicing through the material. Just like a knife cuts through dough, parting tools cut through metal!

Sure! Just let me know what question you want me to answer.

What Is The Primary Function Of A Parting Tool In A Metal Lathe Operation?A parting tool is used in a metal lathe to cut off pieces of metal. You can think of it like a knife that slices through the metal. When you use it, you can separate a finished piece from a larger piece. This helps us make smaller parts that we need.

How Do You Select The Appropriate Parting Tool For Machining Different Materials Or Gear Types?To choose the right parting tool, first, think about the material you are cutting. Different materials, like metal or plastic, need different types of tools. Next, consider the gear type. Some gears have special shapes that need special tools. Finally, always use a tool that fits your machine well for the best results.

What Are The Common Geometries And Specifications To Consider When Choosing A Parting Tool For Gear Production On A Metal Lathe?When choosing a parting tool for making gears on a metal lathe, you need to think about its shape and size. The tool should have a flat edge to cut smoothly. You also want it to be strong enough for hard metals. The width of the tool is important too; it should match the gear’s thickness. Lastly, check that the tool fits well in your lathe and is easy to use.

What Techniques Can Be Employed To Reduce Tool Chatter And Improve Surface Finish When Using A Parting Tool On A Lathe?To stop tool chatter and make a smoother finish while using a parting tool on a lathe, you can try a few things. First, make sure your tool is sharp. A sharp tool cuts better and reduces vibration. Second, use a slower speed when cutting; this helps keep everything steady. Lastly, you can put a bit of cutting oil on the area being worked on to help it glide better.

How Do You Properly Set Up And Align A Parting Tool In A Metal Lathe To Ensure Accurate Cuts On Various Gear Sizes?To set up a parting tool in a metal lathe, you start by placing the tool holder in the machine. Make sure it is tight and secure. Next, adjust the tool’s position so it lines up with the center of the piece you are cutting. You can use a ruler or a caliper to measure this. Lastly, test the setup with a small cut to check if it’s working well before you cut the gears.