Have you ever watched a metal lathe in action? It’s fascinating how this machine shapes metal. One of the key tools used in metal lathe operations is the lathe parting tool. But what exactly does it do? Think of it as a magician’s wand that cuts through metal with ease.

In the world of machining, precision is everything. The lathe parting tool helps achieve that precision by cutting off unwanted pieces of metal. Imagine you’re building a model car. You wouldn’t want extra bits sticking out, right? That’s where parting tools come to the rescue!

While using a lathe, the right tool makes a huge difference. Do you know that parting tools can help create clean edges? This is important for making parts that fit together smoothly. It’s like putting together a puzzle—every piece must be just right.

In this article, we will explore lathe parting tool metal lathe operations. We’ll dive into how they work and why they are crucial for any metalworking project. You’ll discover tips and tricks that can make your projects even better. Get ready to learn something new and exciting!

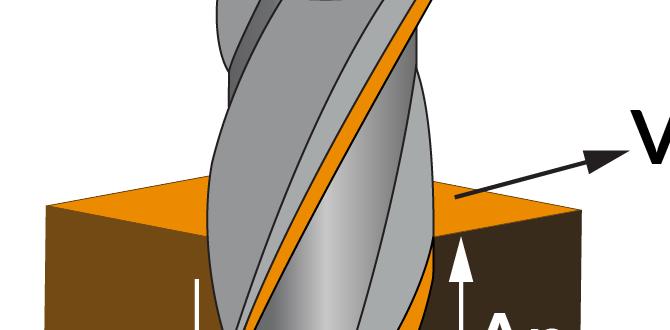

Essential Lathe Parting Tool For Metal Lathe Operations Metal Lathe Operations Are Fundamental In Various Machining Applications, And One Essential Tool That Plays A Critical Role Is The Lathe Parting Tool. This Specialized Tool Is Designed To Cut Through Metal Workpieces, Allowing For Effective And Efficient Machining Processes. In This Article, We Will Explore The Significance Of The Lathe Parting Tool, Its Applications, And Tips For Optimal Use In Metal Lathe Operations. Understanding The Lathe Parting Tool A Lathe Parting Tool Is Specifically Designed For Cutting Off Pieces From A Larger Metal Rod Or Workpiece. It Is Typically Employed To Create Grooves Or Separate Pieces During Lathe Operations. Understanding The Anatomy Of A Parting Tool Is Crucial, As It Consists Of A Blade That Can Vary In Thickness And Size, Depending On The Task At Hand. Applications Of Lathe Parting Tools 1. **Cutting Off Workpieces**: One Of The Primary Uses Of Parting Tools Is To Cut Off Finished Parts Or To Separate Sections Of A Workpiece. This Is Crucial In Production Environments Where Precision Is Necessary. 2. **Creating Grooves**: Parting Tools Are Also Used To Create Grooves For O-Rings Or Other Components That Require A Specific Profile. 3. **Shaping And Profiling**: These Tools Can Assist In Shaping Profiles By Cutting Different Cross-Sections Of A Workpiece, Allowing For Intricate Designs. Choosing The Right Lathe Parting Tool Selecting The Right Lathe Parting Tool Is Vital For The Success Of Metal Lathe Operations. Factors To Consider Include: – **Material**: Ensure The Parting Tool Is Made From High-Speed Steel, Carbide, Or Other Durable Materials To Withstand Metal Cutting. – **Width And Thickness**: The Size Of The Blade Should Match The Specific Job Requirements, Ensuring Optimal Cutting Performance And Reduced Tool Breakage. Tips For Optimal Use – **Feed Rate**: Use A Proper Feed Rate To Minimize Tool Wear And Ensure Smooth Cuts. – **Cutting Speed**: Adjust The Cutting Speed According To The Material Being Worked On; Harder Materials May Require Slower Speeds. – **Coolant Use**: Employ Lubricants Or Coolant To Reduce Friction And Heat Buildup, Which Can Extend The Tool’S Life. Conclusion A Lathe Parting Tool Is An Indispensable Component For Anyone Involved In Metal Lathe Operations. Understanding Its Applications And Proper Usage Can Lead To More Efficient Machining And Better-Quality Parts. By Choosing The Right Tool And Adhering To Best Practices, Operators Can Optimize Their Lathe Operations For Improved Productivity And Precision.

Lathe Parting Tool in Metal Lathe Operations

Discover how a lathe parting tool plays a vital role in metal lathe operations. This tool is crucial for cutting parts from a workpiece with precision. Many hobbyists and professionals use it to create clean, finished edges. Did you know that the design of the parting tool can significantly affect the quality of your cuts? Learning to use this tool properly can make your projects more successful and enjoyable. Don’t underestimate its importance in your metalworking journey!Understanding Lathe Parting Tools

Definition and purpose of parting tools in metal lathe operations.. Different types of parting tools and their specific uses..Parting tools are special tools used in metal lathe operations. They help cut materials into smaller pieces. Think of them as scissors for metal! These tools come in different shapes and sizes, which are made for various tasks.

- Standard Parting Tool: Ideal for straight cuts.

- Grooving Tool: Perfect for making narrow grooves.

- Heavy-Duty Parting Tool: Used for cutting hard materials.

Knowing the right tool for the job makes work easier and safer! Choosing the right parting tool helps you achieve the best results in your metal lathe operations.

What is a parting tool used for?

A parting tool is used for cutting off excess material during metal lathe operations. This makes it easy to create precise shapes and sizes. Parting tools make the metalworking process faster and more efficient.

Components of a Lathe Parting Tool

Material types used in manufacturing parting tools.. Key features and specifications to consider when choosing a parting tool..A lathe parting tool is made with special materials for strength and durability. Common choices include high-speed steel (HSS) and carbide. These materials help the tool cut through metal without losing sharpness.

When picking a parting tool, consider key features like blade thickness and cutting angles. A thicker blade can handle tougher jobs, while the right angle helps with smooth cuts. Don’t forget to check the tool’s length and cooling methods—they can make your work easier. To sum it up, a good parting tool can make you feel like a metal wizard!

| Material | Durability | Best Use |

|---|---|---|

| High-speed Steel | Good | General Cutting |

| Carbide | Excellent | Heavy Metal Cuts |

Selecting the Right Parting Tool for Your Project

Factors influencing the choice of parting tools based on project requirements.. Comparison of various brands and models in the market..Choosing the perfect parting tool is like picking the right pizza topping; it makes all the difference! Key factors include the material you’re working with and the thickness of your pieces. Some projects demand sharper tools, while others might need durability. It can feel overwhelming with so many brands out there. Check out this comparison to make life easier!

| Brand | Type | Best For |

|---|---|---|

| Brand A | High-Speed Steel | Precision cuts |

| Brand B | Carbide | Long-lasting |

| Brand C | Diamond-Coated | Smooth finishes |

Remember, picking the right tool will not only save time but also bring joy to your crafting adventures. Happy parting!

Setting Up Your Lathe for Parting Operations

Stepbystep guide on properly setting up the lathe for parting.. Recommended settings for speed, feed rate, and tool height..Setting your lathe for parting operations is like prepping for a school play. You want everything to be just right! First, choose the correct speed. A good starting point is 300 to 500 RPM, depending on the material. Next, adjust the feed rate; try about 0.002 to 0.005 inches per rev. Finally, ensure that your tool height is aligned with the center of the workpiece—too high, and it’ll be a flop, too low, and it’s just sad! Here’s a handy table to help:

| Settings | Recommended Values |

|---|---|

| Speed (RPM) | 300 – 500 |

| Feed Rate (inches/rev) | 0.002 – 0.005 |

| Tool Height | Center of Workpiece |

Now you’re all set! With the right setup, your lathe work will shine like a star on opening night!

Techniques for Effective Parting on a Metal Lathe

Best practices for executing parting operations successfully.. Common mistakes to avoid during metal lathe parting..Parting on a metal lathe can be tricky. Follow these best practices to make it easier:

- Use a sharp blade: A sharp parting tool makes cleaner cuts.

- Set the right speed: Faster speeds can cause problems. Start slowly.

- Apply steady pressure: Too much pressure can break the tool.

Avoid these common mistakes: Don’t rush your cuts, as this can lead to uneven edges. Always check your setup before starting. Keep your work area clean to prevent accidents.

What is the best way to cut metal using a lathe?

The best way involves using a sharp parting tool, setting a slow speed, and applying gentle pressure. This keeps your cuts clean and safe.

Techniques for success:

- Maintain a steady hand for better control.

- Regularly check the tool for wear and replace if needed.

Maintenance and Care of Parting Tools

Tips for cleaning and maintaining parting tools for longevity.. Signs that indicate it’s time to replace or sharpen your parting tool..Taking care of your parting tools helps them last longer. Clean them after each use. Wipe away dirt and chips to keep them sharp. Proper care prevents rust, which can ruin your tools. Look for these signs that it might be time to replace or sharpen them:

- Dull cutting edges that make work harder

- Visible damage, like chips or cracks

- Difficulty in cutting through materials smoothly

Regular maintenance ensures your tools stay effective and efficient!

How to Clean and Maintain Parting Tools?

Use a soft cloth to remove grime and avoid using harsh chemicals. Keeping tools clean helps them work better.

Safety Considerations When Using Parting Tools

Essential safety precautions to take during parting operations.. Recommended PPE and tools to ensure a safe working environment..Using parting tools safely is a must when operating a lathe. Always wear proper personal protective equipment (PPE), like safety glasses and gloves. Think of these as your superhero gear—keeping you safe while you work! Don’t forget ear protection, too; lathes can be noisier than a rock concert! Always keep your workspace tidy to avoid any “Oops!” moments. Here’s a quick table of essential safety items:

| Item | Purpose |

|---|---|

| Safety Glasses | Protect your eyes from flying debris. |

| Gloves | Prevent cuts and scrapes. |

| Ear Protection | Shield your ears from loud sounds. |

| Steel-Toed Boots | Protect your feet from heavy pieces. |

Following these rules will help you stay safe while you’re the star of the lathe show! Remember, safety first, fun second!

Common Parting Tool Issues and Troubleshooting

Frequently encountered problems during parting operations and their solutions.. How to diagnose wear and tear in parting tools effectively..Parting tools can be tricky little gadgets! Some common issues include breakage, chatter, and poor surface finish. If your tool is wearing out, look for dull edges or chips. Keep an eye on how it performs: if it starts dancing around, that’s chatter! You can fix this by adjusting speeds or feeds. Also, make sure your tool is set straight—no one likes a crooked cut!

| Issue | Solution |

|---|---|

| Chatter | Adjust speed and feed rate |

| Worn Edges | Sharpen or replace tool |

| Breakage | Check tool alignment and speed |

Advanced Techniques and Innovations in Parting Tools

Latest trends in parting tool technology and design enhancements.. Future prospects for parting tools in metal lathe operations..New trends in parting tools focus on smarter designs. Advanced materials make them stronger and lighter. Tools now feature improved cutting edges, which help to reduce wear and tear. These innovations lead to better finishes and faster operations. The future of parting tools looks bright as technology continues to evolve.

- Smart sensors can notify users about tool conditions.

- CNC integration helps machines work more precisely.

- Eco-friendly materials are also gaining popularity.

What are the latest trends in parting tool technology?

Recent trends include the use of advanced materials, smart sensors, and eco-friendly designs. These trends enhance performance and sustainability in metal lathe operations.

Conclusion

In summary, a lathe parting tool is crucial for metal lathe operations. It helps cut metal accurately and creates smooth edges. Understanding how to use it improves your skills. To get the best results, practice regularly and learn more techniques. Check out tutorials or books to deepen your knowledge. You’re on your way to becoming a great machinist!FAQs

What Is The Purpose Of A Parting Tool In Metal Lathe Operations, And How Is It Different From Other Cutting Tools?A parting tool is used in metal lathes to cut off a piece from a bigger metal shape. It helps us make smaller parts quickly. Unlike other tools, it has a thin blade that slices straight through the metal. Other cutting tools can shape or smooth the metal, but the parting tool is special for cutting it apart.

What Are The Key Factors To Consider When Selecting A Parting Tool For Specific Materials In A Metal Lathe?When you pick a parting tool for a metal lathe, think about three main things. First, check the material you are cutting, like steel or aluminum. Different materials need different tool shapes and hardness. Second, consider the size of the cut you want to make. Smaller cuts need thinner tools. Lastly, think about how fast you will be working. Some tools work better at high speeds, while others do not.

How Do You Set Up And Align A Parting Tool In A Lathe For Optimal Cutting Performance?To set up a parting tool in a lathe, first, make sure the tool is clean. Then, firmly attach it to the tool holder. You want the cutting edge to be level with the center of the piece you’re working on. Double-check the tool position by spinning it gently and making sure it doesn’t wobble. Finally, test it by making a slow cut to ensure it works well.

What Are Some Common Issues Encountered During Parting Operations On A Lathe, And How Can They Be Mitigated?When using a lathe for parting, we might see several problems. The tool could get stuck, causing a jam. This happens if the tool is too dull or the cutting speed is too fast. To fix this, you can use a sharper tool and slow down the speed. Another issue is chatter, which makes a loud noise and can ruin the cut. We can reduce chatter by using a steady hand and making sure the piece is secure.

What Safety Precautions Should Be Taken When Using A Parting Tool On A Metal Lathe To Prevent Accidents And Ensure Optimal Results?When using a parting tool on a metal lathe, always wear safety goggles to protect your eyes. Make sure your hair and loose clothing are tied back to avoid getting caught in the machine. Keep your hands away from the moving parts and always use both hands to hold the tool. Lastly, always check the tool and machine before you start to ensure they’re working well.