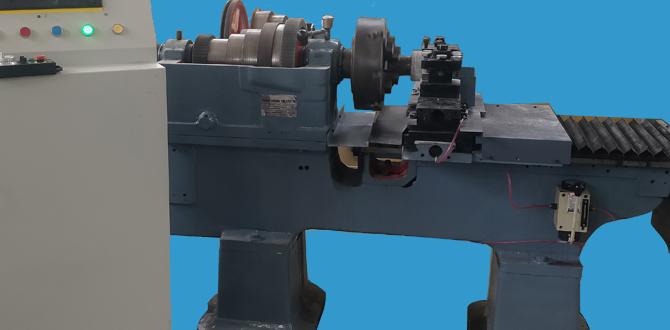

Have you ever watched a metal lathe in action? It can be fascinating to see how metal transforms under skilled hands. One important tool in this process is the lathe parting tool. This tool helps create clean cuts and shapes in metal. But did you know there are quick change tool posts that make it even easier to switch tools?

Imagine you’re working on a project and need to change from cutting to drilling. Wouldn’t it be great if you could do this quickly? With a quick change tool post, you can! This tool holder allows you to swap out tools without wasting time. It’s a favorite among hobbyists and professionals alike.

Using a lathe parting tool with a quick change tool post can speed up your projects. It makes the whole metalworking experience more enjoyable. So, are you ready to learn how to use this amazing combination? Let’s dive into the world of metal lathes and discover all the exciting possibilities!

Lathe Parting Tool For Metal Lathe: Quick Change Tool Post Guide

Understanding Lathe Parting Tools and Quick Change Tool Posts

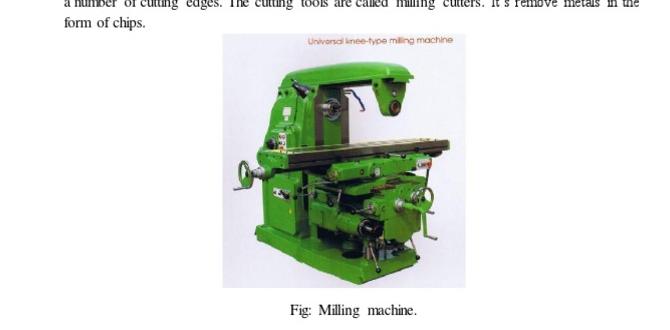

Lathe parting tools are essential for cutting through metal. They help shape and finish your workpieces with precision. A quick change tool post makes switching tools easy and fast, saving you valuable time. Imagine working on a project and needing different tools quickly—this setup makes it smooth and effortless. Fun fact: Using the right parting tool can extend your lathe’s lifespan. Overall, these tools make metalworking more efficient and enjoyable.Understanding Lathe Parting Tools

Definition and function of parting tools in metal lathing. Differences between parting tools and other lathe tools.Parting tools play a fun role in metal lathing! It’s like a magic wand for splitting metal into pieces. These tools help you cut material in a straight line to make smooth edges. Unlike other lathe tools, which shape or grind, parting tools slice right through. Think of them as the superheroes of the lathe world, zooming in to save your project from those pesky leftovers! While other tools act like sculptors, parting tools are direct, getting the job done quickly.

| Type of Tool | Purpose |

|---|---|

| Parting Tool | Cuts material into parts |

| Turning Tool | Shapes the material |

| Boring Tool | Makes holes in material |

Types of Parting Tools

Straight parting tools vs. circular parting tools. Material options for parting tools: Highspeed steel, carbide, and more.Parting tools come in two main styles: straight and circular. Straight tools look like a flat sword, perfect for slicing through metal smoothly. Circular tools, on the other hand, are like tiny pizza cutters, spinning to create rounded cuts. As for materials, you have options like high-speed steel and carbide. High-speed steel is great for general work, while carbide is tougher, making it last longer. Remember, choosing the right tool can make all the difference!

| Tool Type | Material | Best For |

|---|---|---|

| Straight Parting Tool | High-speed Steel | Basic metal cutting |

| Circular Parting Tool | Carbide | Heavy-duty tasks |

Benefits of Using a Quick Change Tool Post

Advantages of quick change systems over traditional tool posts. How quick change tool posts improve efficiency in operations.Quick change tool posts offer major perks over old tool posts. They help you switch tools fast, saving time and effort. This means you can finish jobs quicker and get more done. Here are some benefits:

- Less downtime during tool changes.

- Improved accuracy with easy adjustments.

- Better use of your workspace.

- More tools ready to use at all times.

With quick change tool posts, operations flow smoothly. They make work easier, making them a great choice for any workshop.

What are the key advantages of quick change tool posts?

Using quick change tool posts speeds up tool changes. This means more work gets done in less time. Plus, they improve safety by reducing manual handling.

Installing a Quick Change Tool Post on Your Metal Lathe

Stepbystep guide to installation. Common challenges and solutions during installation.Installing a quick change tool post on your metal lathe can feel like assembling a puzzle, but don’t worry! Start by cleaning your lathe’s surface; dirt has no business here! Next, follow these simple steps:

| Step | Action |

|---|---|

| 1 | Remove the old tool post. |

| 2 | Align the new tool post with the mounting surface. |

| 3 | Secure it tightly, but not too tight—no one likes an over-tightened sandwich! |

Common challenges include alignment issues and loose fittings. If your tool post wobbles, try tightening the screws or checking the alignment again. Remember, a stable tool post makes for happy turning! So, embrace your inner tool boss and get that post installed!

Choosing the Right Parting Tool for Your Projects

Factors to consider: material, cutting depth, and workpiece type. Recommendations for specific applications.Choosing your parting tool is like picking the right superhero for your project. First, think about the material you’ll be cutting. Different tools work better for various metals. Next up, consider cutting depth; a deeper cut requires a tougher tool! Lastly, know your workpiece type. Is it small and delicate or big and bulky? These factors will help you find the perfect fit.

| Application | Recommended Tool Material |

|---|---|

| Aluminum | High-Speed Steel |

| Steel | Cobalt |

| Bronze | Carbide |

So before you dive in, remember: the right tool can save you time. Well, that and maybe a few extra band-aids for your fingers!

Maintenance Tips for Longevity of Parting Tools

Proper cleaning and sharpening techniques. Signs that your parting tool needs replacing.To keep your parting tools in top shape, proper cleaning is essential. After each use, wipe off chips and debris. A clean tool cuts better and lasts longer. For sharpening, use a fine stone. Just a few strokes can restore that sharp edge. Watch for signs that it’s time to say goodbye. If it chips or feels dull, it’s replacement time. Remember, a bad tool is like a bad haircut—everyone notices!

| Signs Your Tool Needs Replacing | Action |

|---|---|

| Dull edge | Sharpen or replace |

| Chips | Replace |

| Uneven cuts | Adjust or replace |

Safety Considerations When Using Parting Tools

Essential safety gear and precautions. Common accidents and how to avoid them.When using parting tools, safety is very important. Always wear the right safety gear. This includes goggles, gloves, and ear protection to keep safe from flying chips and loud noises. Accidents can happen, like fingers getting too close to the blade. You can avoid these by:

- Keeping hands away from the cutting area.

- Securing the workpiece properly.

- Using the tool correctly and following instructions.

Being cautious helps keep everyone safe while enjoying your work!

What safety gear is important for using parting tools?

Wearing goggles, gloves, and ear protection is essential for safety.

Comparing Traditional vs. Quick Change Tool Posts

Pros and cons of each system. Realworld examples and user experiences.Each tool system has its strengths and weaknesses. Traditional tool posts are strong and reliable. They hold tools firmly but take time to change. Users sometimes complain about the slow switching process. In contrast, quick change tool posts speed up work. They make switching tools easy and fast. However, they may not hold tools as tightly. Here’s a quick look at their pros and cons:

- Traditional Tool Post: Reliable, firm tool hold, but slow changes.

- Quick Change Tool Post: Fast tool changes, but less stability.

Many metalworkers prefer quick changes. One user said it saved them 30% in time. Choose your system based on what your projects need!

What are the main differences between traditional and quick change tool posts?

The main differences are speed and stability. Quick change tool posts allow quicker tool swaps, while traditional ones offer more secure holds. This choice can affect overall project efficiency.

Maximizing Productivity with Effective Tool Management

Organizing tools for quick access. Strategies for maintaining consistency and quality in lathe work.Keeping tools organized boosts productivity. Use a tool post that allows for fast changes. This lets you grab what you need quickly. Always check your tools’ condition. Consistency leads to better work. Here’s how to ensure quality:

- Store tools in the same place every time.

- Inspect tools before starting a project.

- Clean tools regularly to maintain sharpness.

With the right setup, you can work efficiently and create great results!

How can I keep my lathe tools organized?

Use a designated area or toolbox for each tool. This makes it easy to find what you need.

Conclusion

In summary, a lathe parting tool is essential for cutting metal smoothly. The quick change tool post lets you switch tools easily, saving time. You can create precise shapes and designs with practice. We encourage you to explore more about lathe tools and techniques. Start experimenting in your workshop for hands-on learning. Your skills will grow with every project!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Quick Change Tool Posts For Metal Lathes:Sure! Lathe parting tools help cut metal pieces from larger ones. They are like scissors for metal. Quick change tool posts let you switch tools easily and quickly. This saves time when you work on different projects. Using these tools can make your work easier and more fun!

Sure! Please ask your question, and I’ll be happy to help you with a simple answer.

What Are The Key Features To Look For In A Parting Tool Designed For Use With A Metal Lathe?When looking for a parting tool for a metal lathe, you should check a few key features. First, choose one with a sharp cutting edge. This helps the tool cut through metal easily. Next, look for a sturdy handle. A strong handle gives you better control while working. Finally, make sure the tool is the right size for your lathe. Using the right size helps you work safely and effectively.

How Does A Quick Change Tool Post Improve Efficiency And Accuracy In Lathe Operations Compared To Standard Tool Posts?A quick change tool post helps you switch tools faster on a lathe, which is a machine that spins metal. Instead of taking a long time to change tools, you can do it in seconds. This saves time, so you can finish your work quicker. It also helps you get better and more precise cuts, which means your work will look nicer and fit better.

What Materials Are Commonly Used To Manufacture Lathe Parting Tools, And How Do These Materials Affect Their Performance In Metalworking?Lathe parting tools are often made from high-speed steel and carbide. High-speed steel is tough and can last a long time. Carbide, on the other hand, is even harder and stays sharp longer. Using these materials helps you cut metal easily and smoothly. They make your work faster and more precise.

Can You Explain The Process Of Setting Up And Adjusting A Quick Change Tool Post For Optimal Tool Alignment And Performance?To set up a quick change tool post, first, lock it in place on your machine. Next, choose the tool you want to use and slide it into the tool holder. Tighten it so it stays put. Then, check the tool’s height by adjusting it until it lines up with the workpiece. Finally, make small adjustments if needed to ensure everything cuts smoothly.

What Safety Precautions Should Be Taken When Using A Parting Tool On A Metal Lathe To Prevent Accidents And Ensure Proper Operation?When using a parting tool on a metal lathe, always wear safety goggles to protect your eyes. Make sure your hands and clothes are away from the spinning tool. Check that the tool is tight and secure before starting. Do not talk to anyone while the lathe is running. Finally, keep your workspace clean to avoid tripping or accidents.