Imagine you’re in a workshop, ready to create something amazing. Have you ever seen a lathe in action? It’s a fascinating tool. Today, we’re diving into how to use a lathe parting tool for your metal lathe setup.

Most people think lathe work is hard. But with the right tools and tips, it can be fun and rewarding. A parting tool is special. It lets you cut through metal with ease when you’re shaping and finishing your projects.

Let’s also consider a fun fact! Did you know that parting tools date back hundreds of years? They have helped artisans create beautiful metal pieces since ancient times. So, if you want to design something of your own, understanding this tool is essential.

Are you ready to learn the secrets of using a lathe parting tool? Let’s explore how to properly set up your metal lathe. Your next project awaits!

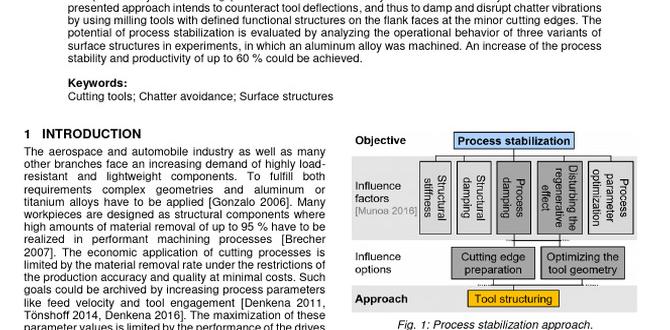

Lathe Parting Tool: Effective Metal Lathe Setup Guide

Lathe Parting Tool Metal Lathe Setup

Setting up a lathe parting tool on a metal lathe is crucial for precise cutting. By properly adjusting the tool, you ensure smoother finishes and increased accuracy. Did you know that using the right cutting speed can make a huge difference? Many beginners overlook this, leading to rough edges. Experimenting with different depths of cut can also improve your projects. Remember, a well-set tool not only saves time but enhances your overall experience in metalworking.Understanding Lathe Parting Tools

Definition and purpose of parting tools in metal lathes. Key features differentiating parting tools from other cutting tools.Lathe parting tools are special tools used with metal lathes to cut off parts of a workpiece. Their main job is to create a clean break between sections. Think of them like scissors for metal! Unlike regular cutting tools, parting tools are thinner and sharper, allowing for precise cuts without much effort. They help make quick work of shaping and finishing projects. Here’s a quick look at how they differ:

| Feature | Parting Tool | Other Cutting Tools |

|---|---|---|

| Thickness | Thin | Thicker |

| Purpose | Cut off parts | Shaping and finishing |

| Precision | High | Varies |

Using a lathe parting tool is like having a trusty sidekick in your workshop. They might not save the world, but they definitely save time and make things easier!

Choosing the Right Parting Tool

Factors to consider when selecting a parting tool (material, size, design). Comparison of different types of parting tools available in the market.Picking the right parting tool is essential for shaping metal correctly. You need to think about material, size, and design. Different tools suit different tasks. For instance, larger tools may handle thicker metal. Let’s look at some common options:

- High-speed steel (HSS) tools are strong and last long.

- Cobalt tools work well with tough materials.

- Carbide tools stay sharp, even after lots of use.

Choosing wisely helps you work safely and effectively!

What factors should you consider when selecting a parting tool?

Consider the material, size, and design of the tool for the best results. These factors can make a big difference in your work quality.

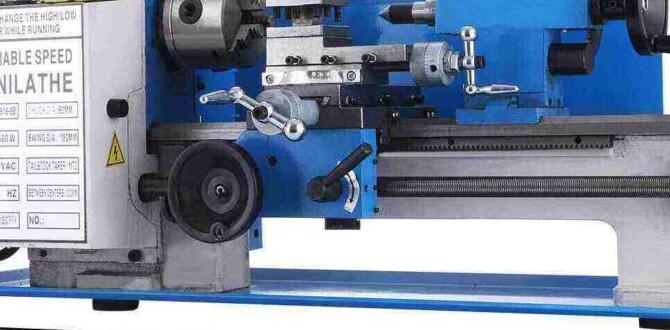

Preparing the Metal Lathe for Parting

Stepbystep guide to set up the lathe for parting operations. Tools and accessories needed for a successful setup.Before you start cutting metal, you must prepare your lathe. First, make sure the lathe is clean and safe. Next, gather your tools. You will need:

- A parting tool

- A tool post

- Lubricant oil

- A measuring tool

Now, attach the parting tool securely to the tool post. Check the settings carefully. Ensure you adjust the speed to a safe level. Lastly, run a test cut on scrap metal. This step helps in fine-tuning your setup.

What tools do I need for parting on a lathe?

You will need a parting tool, a tool post, lubricant oil, and a measuring tool to set up your lathe properly. These tools ensure a smoother and safer cutting experience.

Proper Techniques for Using a Parting Tool

Best practices for feeding and maintaining speed during parting. Tips for achieving clean cuts and avoiding tool breakage.Using a parting tool is like cutting cake, but with metal! Start by adjusting your lathe speed. A good rule is to keep it around 450-800 RPM. Feed your tool smoothly, not too fast or slow, to avoid breakage. Clean cuts need patience. If you rush, the tool might chip. Remember, sharp tools are happy tools. They cut better and last longer.

| Speed (RPM) | Feed Rate | Tip |

|---|---|---|

| 450-800 | Even and steady | Use sharp tools! |

Troubleshooting Common Issues

Identification of common problems encountered during parting. Solutions and preventative measures to enhance tool performance.Parting on a lathe can be tricky. It’s normal to face some problems while using your tools. Common issues include tool wear, chatter, and poor surface finish. Fortunately, there are ways to solve these problems. Here are some tips:

- Inspect tools regularly for wear.

- Adjust speed and feed rates to reduce chatter.

- Keep tools sharp for a smoother finish.

Taking these steps can improve your experience and results. Remember, the right setup is key!

What are common problems with a lathe parting tool?

Some common problems include tool chatter, poor surface finish, and rapid tool wear.

How can I enhance tool performance?

You can enhance tool performance by regularly checking the tools and adjusting speeds.

Maintenance of Parting Tools

Routine maintenance practices for longevity of parting tools. Cleaning and storage tips for optimum performance.To keep your parting tools working well, regular maintenance is vital. Clean them after each use. This prevents dirt buildup. Use a soft brush or cloth for gentle cleaning. Store them properly, too. Keep tools in a dry place to avoid rust. Here are some tips:

- Check for chips and wear regularly.

- Lubricate moving parts as needed.

- Use a dedicated storage box or tool rack.

Your tools will last longer this way. So, take care of them, and they will take care of you!

How do I clean and store my parting tools?

Wash with a soft cloth, and store in a dry place. This keeps them safe and ready for use!

Real-World Applications of Parting Tools

Examples of projects where parting tools are essential. Benefits of mastering parting techniques in various industries.Parting tools play a vital role in many projects. For example, they are essential in creating parts for cars, machinery, and hand tools. Mastering these tools offers big benefits. They help save time and improve accuracy. With skilled use, industries can produce high-quality parts faster and at lower costs.

- Automotive industry: Making precise cuts for engine parts.

- Manufacturing sector: Producing gears and fixtures efficiently.

- Woodworking: Crafting detailed furniture components.

What are the benefits of using parting tools?

Using parting tools enhances efficiency and precision. This leads to better quality products. Workers can finish their tasks more quickly and with fewer mistakes.

Conclusion

In summary, a lathe parting tool is essential for cutting metal accurately. Setting up your metal lathe correctly ensures clean cuts and improves safety. Always check your tool and lathe settings before starting. For more tips on lathe setup, consider reading tutorials or watching videos. Practice makes perfect, so get hands-on and enjoy your metalworking journey!FAQs

What Is The Proper Way To Set Up A Parting Tool On A Metal Lathe For Optimal Cutting Performance?To set up a parting tool on a metal lathe, first make sure the tool is sharp and clean. Then, place the tool holder at the right height so it lines up with the center of the metal piece. Tighten everything so it stays in place. Finally, set the lathe to a slow speed to start cutting carefully. This helps you get a smooth cut.

How Do You Adjust The Cutting Height Of A Parting Tool To Achieve Clean Cuts Without Damaging The Workpiece?To adjust the cutting height of a parting tool, you need to make small changes. First, raise or lower the tool holder until you find the right spot. You want the tool to just touch the workpiece lightly. This way, you can make clean cuts without hurting the material. Always check the cut as you go to ensure it stays nice.

What Types Of Parting Tools Are Available For Metal Lathes, And How Do Their Designs Impact Setup And Usage?There are different types of parting tools for metal lathes. One common type is the straight parting tool, which cuts straight down. Another is the grooving tool, which makes small grooves. The shape and size of these tools affect how you set them up and use them. Some might need more careful setup to stay stable while cutting.

What Are The Common Issues Encountered During Parting Operations On A Metal Lathe, And How Can They Be Mitigated?When we use a metal lathe to cut parts, we can face some common problems. Sometimes, the tool can get stuck, making it hard to cut. We can help this by using a sharp tool and moving slowly. Another issue is vibrations, which can make the cut uneven. To fix this, we should make sure everything is tight and balanced.

How Does The Speed And Feed Rate Affect The Performance Of A Parting Tool When Machining Different Types Of Metals?When you use a parting tool, the speed and feed rate matter a lot. If you go too fast, the tool can get hot and break. If you go too slow, it might not cut well and get stuck. Different metals need different speeds and feeds to work best. So, it’s important to pick the right settings for the metal you’re cutting.