Have you ever wondered how simple tools can create amazing things? Take the lathe parting tool, for example. This special tool works alongside a metal lathe to make precise cuts. It might look small, but it plays a big role in shaping metal pieces.

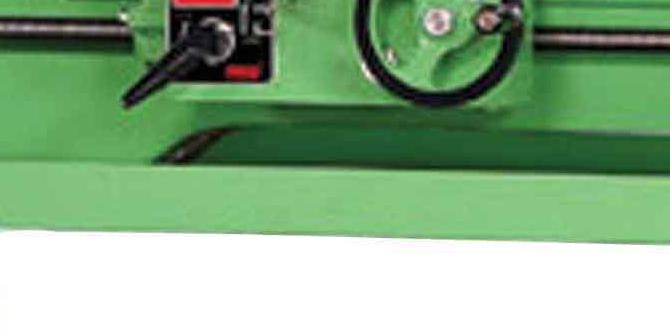

Imagine you’re in a workshop, surrounded by machines. The air buzzes with energy, and a metal lathe stands proudly in the corner. With the right tools, you can turn raw metal into something useful. But what happens if you don’t have the right stand for it? A sturdy metal lathe stand is just as important as the lathe itself. It keeps everything steady and secure.

Did you know that many woodworkers and metalworkers swear by their lathe setups? They believe a good stand can make a world of difference. With the right support, your creations can come to life, and that’s quite exciting!

Let’s dive deeper into the world of lathe parting tools and metal lathe stands. You’ll discover what makes these tools special and how they can help you unlock your creative potential!

Essential Lathe Parting Tool For Your Metal Lathe Stand

Understanding Lathe Parting Tools and Metal Lathe Stands

Lathe parting tools help cut metal precisely. They allow for clean, straight edges on your projects. A sturdy metal lathe stand is essential. It keeps the lathe steady while you work, improving accuracy and safety. Did you know that a good stand can reduce vibrations? This makes your cuts smoother. The right tools and setup can make any project easier and more enjoyable, whether you’re a beginner or a pro in metalworking.Understanding Lathe Parting Tools

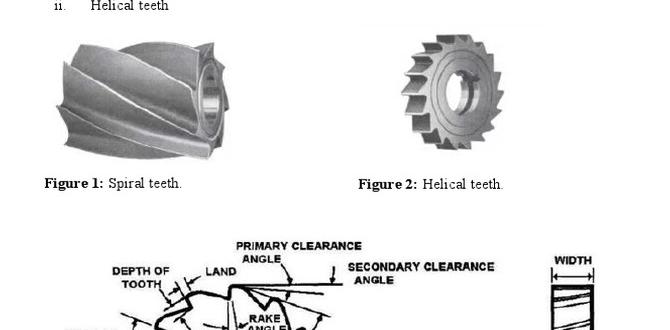

Definition and purpose of parting tools in metalworking.. Types of parting tools and their specific applications..A lathe parting tool is a sharp tool used in metalworking to cut off parts of material. Its main purpose is to create clean and precise cuts, helping makers shape metal pieces easily. Think of it like a pizza cutter, slicing through dough but with metal! There are a few types of parting tools, each fitting different tasks. For example, some are good for cutting thin sections, while others are designed for thicker materials. Here’s a quick breakdown:

| Type | Application |

|---|---|

| Standard Parting Tool | General cutting tasks. |

| Threading Parting Tool | Making threads on a lathe. |

| Grooving Tool | Creating grooves or slots. |

Each tool has its own special job, making your work easier and more fun! Just like having a toolbox filled with the right gadgets, these tools help you achieve your metalworking dreams!

Choosing the Right Parting Tool for Your Metal Lathe

Factors to consider: material, size, and geometry.. Comparison between HSS, carbide, and ceramic parting tools..When picking a parting tool for your metal lathe, several factors come into play. First up is material. High-Speed Steel (HSS) is tough but dulls faster than carbide, which stays sharp longer. Ceramic tools? They can be as strong as a bull but too brittle at times. Size matters too! A wider tool cuts faster but can be tricky. Lastly, consider geometry. A good shape helps avoid snags and keeps your project flowing. Here’s a quick comparison for a laugh:

| Material | Durability | Cost |

|---|---|---|

| HSS | Medium | Low |

| Carbide | High | Medium |

| Ceramic | Very High | High |

Consider these points wisely, and you’ll find your perfect match! Remember, every tool can be a hero—only if you choose it right!

Setup and Adjustment of Lathe Parting Tools

Best practices for mounting parting tools on a metal lathe.. Tips for adjusting tool height and feed rate for optimal performance..Mounting parting tools on a metal lathe correctly is key for great results. First, ensure the tool is tight and securely fastened. Check that it’s in line with the workpiece. Adjusting tool height is also important. Keep the tool tip level with the center line of the lathe. Use these tips for the best outcome:

- Check the mounting system for any wear.

- Use a digital caliper to measure tool height.

- Set the feed rate low for deep cuts.

- Make small adjustments to improve performance.

How do I adjust the tool height on a lathe?

To adjust tool height, align the tool tip with the center of the workpiece. Use a ruler or caliper for accuracy. Keep it steady for smooth operation!

Common Techniques for Using a Lathe Parting Tool

Stepbystep guide to executing a parting operation.. Troubleshooting common issues during parting..Using a lathe parting tool can feel tricky, but it’s easier than you think! First, secure your workpiece firmly on the lathe. Next, set the tool at the right angle. Slowly lower it into your material. Remember, patience is key; rushing can lead to a messy cut.

Now, if you encounter problems, don’t panic! Common issues include chatter and jagged edges. Adjust your feed rate or change the tool angle. If you’re still stumped, take a break. Sometimes a fresh mind solves everything, even if it means stepping away for a snack!

| Common Issues | Solutions |

|---|---|

| Chatter | Adjust feed rate |

| Jagged edges | Change tool angle |

Follow these steps, and soon you’ll be parting like a pro! Who knows? You might even impress your friends and family with your newfound lathe skills. But be careful—don’t forget to wear your safety gear and keep your fingers clear of the spinning action!

Maintenance and Care for Longevity of Parting Tools

Cleaning and sharpening techniques for your parting tools.. Storage best practices to avoid damage or dulling..Taking care of your parting tools is key for them to stay sharp and last longer. Start by cleaning them regularly to remove any metal shavings. A soft brush or cloth works wonders! For sharpening, use a fine stone or a specialized sharpener—think of it as giving them a little spa treatment. And remember, store them safely. A drawer or a toolbox lined with foam can keep them from getting bumped around or dulled. Just imagine them lounging in their cozy home during their off time!

| Maintenance Step | Tips |

|---|---|

| Cleaning | Use a soft brush or cloth. |

| Sharpening | Try a fine stone or specialized sharpener. |

| Storage | Keep in a foam-lined drawer or toolbox. |

Integrating a Metal Lathe Stand: Benefits and Best Options

Importance of a stable stand for precision and safety.. Recommended metal lathe stands compatible with various sizes and models..A strong metal lathe stand is vital for safety and accuracy. It prevents vibrations that can mess up your work. A sturdy base keeps the lathe steady, which is important when making precise cuts. Choosing the right stand makes a big difference.

Here are some recommended stands:

- Tool-Post Stands: Great for smaller lathes.

- Heavy-Duty Stands: Best for larger models.

- Portable Options: Easy to move and set up.

Why is a stable stand important?

A stable stand helps you work safely and accurately. It reduces the chance of accidents and ensures better results with your lathe.

What types of stands work with different lathes?

You can find various stands that fit many lathe sizes. Look for features that match your model for the best performance.

Enhancing Your Metalworking Setup

Additional tools and accessories to complement your lathe parting tool.. Safety equipment necessary for safe lathe operation..To improve your metalworking setup, adding extra tools is a smart choice. Useful items include calipers for precise measurements, and cutting fluids to keep your lathe cool. Safety gear is crucial too. Always wear a face shield and ear protection while operating your lathe. Here’s a quick list:

- Safety glasses

- Dust mask

- Work gloves

This combination helps you work safely and effectively. A well-equipped workshop leads to better results!

What tools do I need with a lathe parting tool?

You need measuring tools, cutting fluids, and proper safety equipment.

Real-Life Applications of Parting Tools in Metalworking

Showcase of industries and projects where parting tools are indispensable.. Case studies highlighting successful uses of parting tools..Parting tools are crucial in many industries. They help cut metal pieces smoothly. In factories, workers use them for precision cutting. For example, in automobile manufacturing, parting tools shape gears and shafts. In jewelry making, they craft beautiful designs. These tools save time and enhance accuracy.

- Automobiles: Creating gears and components

- Aerospace: Shaping engine parts accurately

- Construction: Making strong metal fittings

- Jewelry: Designing intricate pieces

Studies show that using parting tools increases efficiency. A leading automotive company improved its production speed by 30% with these tools. Overall, parting tools make metalworking projects easier and more effective.

What industries use parting tools in metalworking?

Parting tools are widely used in automotive, aerospace, construction, and jewelry industries. They help shape metal parts quickly and with high precision.

Conclusion

In conclusion, a lathe parting tool is essential for cutting metal accurately. Choosing the right metal lathe stand helps stabilize your work. Together, they improve your projects and make crafting easier. You can experiment with different tools to see what works best for you. Keep learning and exploring more about metalworking to boost your skills and creativity!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Stands:Sure! A lathe parting tool helps cut metal shapes, so we can make things like pieces for toys. We hold it in a machine called a lathe, which spins the metal. A metal lathe stand keeps the lathe stable while we work on it. It’s important to have a good stand to keep everything safe and steady. With the right tools, you can create cool projects!

Sure! Please share the question you want me to answer.

What Are The Main Types Of Parting Tools Used In Metal Lathes, And How Do They Differ In Design And Application?There are a few main types of parting tools used in metal lathes. First, we have straight parting tools. These have a flat, straight edge to cut straight lines. Next, we have tipped parting tools, which have a smaller, angled tip for more detailed work. Lastly, we find blade-type parting tools, which are thin and allow for precise cuts. Each type is made for different kinds of work, depending on what you need to cut.

How Can The Setup Of A Metal Lathe Stand Impact The Precision And Stability Of Parting Operations?The setup of a metal lathe stand is very important. If the stand is sturdy and level, the lathe will work better. This means that when you cut pieces, they will be straight and even. If the stand wobbles or is uneven, your cuts can be messy and not fit well. So, a good setup helps you make better parts!

What Materials Are Commonly Used For Parting Tool Blades, And How Do They Affect Cutting Performance?Parting tool blades are often made from high-speed steel, carbide, or ceramic. High-speed steel is strong and sharp, making it good for many jobs. Carbide is harder and lasts longer, so you won’t need to change it often. Ceramic can be very sharp but may break easily. The material you choose affects how well the blade cuts and how long it lasts.

What Safety Precautions Should Be Taken When Using Parting Tools On A Metal Lathe?When using parting tools on a metal lathe, you should always wear safety goggles to protect your eyes. Keep your hands and fingers away from the spinning parts. Make sure your hair and clothes are out of the way so they don’t get caught. Always check that tools are sharp and in good shape before you start. If you feel unsure, ask an adult for help.

How Can The Height And Position Of A Metal Lathe Stand Be Adjusted To Optimize Ergonomics And Reduce Operator Fatigue During Long Machining Sessions?You can adjust the height of a metal lathe stand so that it matches your elbow level. When you stand or sit, your arms should be relaxed. This way, you can work without straining your back or arms. Also, move the lathe closer to you to avoid leaning forward. This helps keep you comfortable during long sessions.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Parting Tools And Metal Lathe Stands:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe parting tool helps cut metal shapes, so we can make things like pieces for toys. We hold it in a machine called a lathe, which spins the metal. A metal lathe stand keeps the lathe stable while we work on it. It’s important to have a good stand to keep everything safe and steady. With the right tools, you can create cool projects!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please share the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Main Types Of Parting Tools Used In Metal Lathes, And How Do They Differ In Design And Application?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are a few main types of parting tools used in metal lathes. First, we have straight parting tools. These have a flat, straight edge to cut straight lines. Next, we have tipped parting tools, which have a smaller, angled tip for more detailed work. Lastly, we find blade-type parting tools, which are thin and allow for precise cuts. Each type is made for different kinds of work, depending on what you need to cut.”}},{“@type”: “Question”,”name”: “How Can The Setup Of A Metal Lathe Stand Impact The Precision And Stability Of Parting Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The setup of a metal lathe stand is very important. If the stand is sturdy and level, the lathe will work better. This means that when you cut pieces, they will be straight and even. If the stand wobbles or is uneven, your cuts can be messy and not fit well. So, a good setup helps you make better parts!”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Parting Tool Blades, And How Do They Affect Cutting Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Parting tool blades are often made from high-speed steel, carbide, or ceramic. High-speed steel is strong and sharp, making it good for many jobs. Carbide is harder and lasts longer, so you won’t need to change it often. Ceramic can be very sharp but may break easily. The material you choose affects how well the blade cuts and how long it lasts.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Using Parting Tools On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using parting tools on a metal lathe, you should always wear safety goggles to protect your eyes. Keep your hands and fingers away from the spinning parts. Make sure your hair and clothes are out of the way so they don’t get caught. Always check that tools are sharp and in good shape before you start. If you feel unsure, ask an adult for help.”}},{“@type”: “Question”,”name”: “How Can The Height And Position Of A Metal Lathe Stand Be Adjusted To Optimize Ergonomics And Reduce Operator Fatigue During Long Machining Sessions?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can adjust the height of a metal lathe stand so that it matches your elbow level. When you stand or sit, your arms should be relaxed. This way, you can work without straining your back or arms. Also, move the lathe closer to you to avoid leaning forward. This helps keep you comfortable during long sessions.”}}]}