Have you ever watched a metal lathe in action? It’s quite fascinating! A lathe spins metal to create all sorts of parts. But one important tool that helps in this process is the lathe parting tool. It allows the lathe to cut through metal cleanly and efficiently.

Many people don’t realize how much torque is involved. Torque is a measure of how much force is used to turn something. On a metal lathe, the right torque makes a huge difference in how well the parting tool works. Too little torque can cause problems, while too much can break the tool!

Picture this: you’re making a metal piece for a school project. If you don’t use the right amount of torque with your lathe parting tool, your project could end up as a mess. Don’t let that happen! Let’s explore how metal lathe torque and proper tool usage can lead to perfect results every time.

Lathe Parting Tool: Mastering Metal Lathe Torque Effortlessly

Lathe Parting Tool for Metal Lathe Torque

The lathe parting tool is essential in shaping metal pieces. It helps create accurate cuts, making your projects tidier. Did you know that the right torque can improve your results? When using a metal lathe, adjusting the torque ensures better control. This leads to less wear on your tools and longer-lasting performance. Knowing how to use a parting tool effectively can also save time and effort, making your metalworking journey smoother and more enjoyable!What is a Lathe Parting Tool?

Definition and function of parting tools in metal lathes. Common applications in machining processes.A lathe parting tool is a special cutting tool. It works with metal lathes to shape and cut materials. Parting tools help create grooves and separate pieces of metal. They can cut deep and produce clean edges. This tool is key in many machining tasks.

- Used to cut off parts of metal

- Helps create slots and grooves

- Ideal for shaping metal pieces

Parting tools are common in workshops and factories. They make metal crafting easy and precise.

What are the common uses of lathe parting tools?

The **common uses** of lathe parting tools include:

- Cutting metal parts into smaller sections.

- Creating slots for assembly or fit.

- Making decorative grooves in metal.

Importance of Torque in Lathe Operations

Explanation of torque and its significance in lathe performance. How improper torque affects machining accuracy and tool longevity.Torque is like the superhero of lathe operations. It helps the machine cut metal smoothly. Too little torque? It’s like trying to open a pickle jar with wet hands—frustrating and messy! Too much torque? Your tools might wear out faster than your favorite shirt in a food fight. The right torque keeps everything balanced, leading to better accuracy and longer tool life. A happy lathe makes for a happy machinist!

| Torque Level | Effect |

|---|---|

| Too Low | Poor cutting, rough finishes |

| Just Right | Precise cuts, smooth finishes |

| Too High | Tool damage, inaccurate machining |

Choosing the Right Parting Tool for Your Metal Lathe

Factors to consider when selecting parting tools (material, size, shape). Recommended brands and models for optimal performance.Picking the right parting tool for your metal lathe is important. First, think about the material. High-speed steel is popular for its strength. Next, consider the size. A smaller tool is better for thin materials. The shape also matters; a flat tool works well for straight cuts.

Here are some trusted brands:

- ToolNerds

- Machinist Source

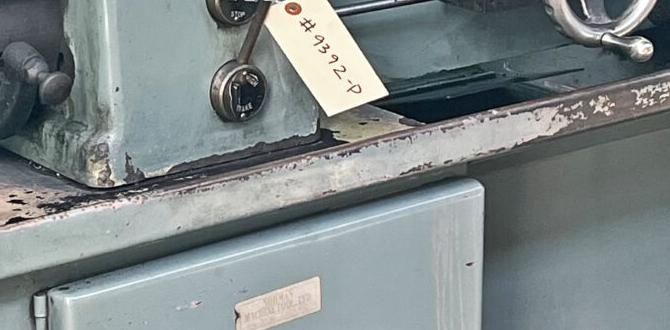

- Grizzly Industrial

Each brand has models designed to last and perform well. Choose wisely for the best results!

What should I look for in a parting tool?

Look for a tool with high durability and the right size. A good fit means cleaner cuts and less hassle. Quality materials will also increase longevity.

Setting Up and Using Parting Tools Effectively

Stepbystep guide on correct setup for metal lathes. Best practices for operating parting tools to enhance efficiency.Setting up parting tools correctly is key for a smooth experience on a metal lathe. Start by ensuring the tool is sharp and free from damage. Securely attach it to the tool post, using a sturdy clamp. Adjust the height properly for the best cutting angle. Here are some best practices to follow:

- Use plenty of cutting oil to reduce friction.

- Take light cuts to avoid tool breakage.

- Maintain consistent speed for a cleaner edge.

- Keep eyes on the tool as you work for safety.

Following these steps enhances efficiency and ensures your work is precise.

How do I improve my technique with a parting tool?

Improving technique with a parting tool comes from practice and attention to detail. Focus on steady feed rates and the right depth of cut. These steps will help you create cleaner finishes with less effort.

Common Problems with Lathe Parting Tools

Typical issues faced during parting and their causes. Troubleshooting tips for improving performance.Parting tools can cause problems when cutting metal. Common issues include:

- Sawing too slowly: This slows down cutting.

- Too much torque: This can break the tool.

- Material sticking: The metal may cling to the tool.

To fix these problems, try the following:

- Increase the speed of cutting.

- Reduce the pressure on the tool.

- Use proper lubrication.

With these tips, you can make the most of your lathe parting tool.

What are the main issues with lathe parting tools?

Common problems include slow cutting speeds, excessive torque, and materials sticking to the tool.

What can improve lathe tool performance?

Improving speed, reducing pressure, and using lubrication can enhance performance.

Maintenance Tips for Longevity of Lathe Parting Tools

Routine care and maintenance practices. How proper maintenance affects torque and cutting efficiency.Taking care of lathe parting tools is key for keeping them sharp and ready to go. Regular cleaning helps remove metal shavings and grime. Remember to check for any wear and tear—like an old shoe, a worn tool can slip and miss the mark! Proper maintenance can boost torque and cutting efficiency, making your work smoother. Want an easy “care” plan? Here’s a quick table:

| Task | Frequency |

|---|---|

| Clean tools | After each use |

| Inspect for damage | Weekly |

| Sharpen cutting edges | Monthly |

By sticking to these tips, your lathe parting tools will be happy and effective, just like a well-fed cat!

Enhancing Lathe Performance through Torque Management

Techniques for measuring and adjusting torque during operations. Tools and equipment that assist in torque management.Running a lathe is like driving a race car; you want everything to run smoothly. First, measure your *torque* accurately using a torque wrench. This tool helps you ensure that everything is clamped tight, so parts don’t fly off—nobody wants a surprise ‘lathe party’! You can also use torque tables to find the right settings for your projects. Before you know it, you’ll be the torque master at your shop!

| Tool | Purpose |

|---|---|

| Torque Wrench | Measures torque to ensure proper tightness |

| Torque Tables | Guide settings for various materials and sizes |

With the right tools, managing torque can turn your lathe into a superstar. Remember, a happy lathe means happy parts!

Future Trends in Lathe Parting Tools and Technologies

Innovations in parting tool design and materials. The impact of technology on metal lathe operations and torque efficiency.Innovations are changing lathe parting tools. New designs use lighter and stronger materials. This improves cutting speed and accuracy. Technology also helps make lathe operations smoother. It boosts torque efficiency, meaning less energy use. As tools get smarter, we may see:

- Special coatings for less friction.

- Smart sensors for real-time monitoring.

- 3D printing for custom tool shapes.

These updates can make work easier and faster. Keeping up with trends is key for better results.

What are the benefits of new lathe parting tools?

The main benefits of new lathe parting tools are improved efficiency, accuracy, and cost-effectiveness. They help save time and energy while providing better results for metalworking projects.

Conclusion

In summary, a lathe parting tool is essential for cutting metal on a lathe. Understanding torque helps you control the tool better. Always ensure your tool is sharp for clean cuts. Remember to follow safety protocols while working. You can explore more about lathe techniques to improve your skills. Let’s keep learning and making great projects together!FAQs

What Factors Influence The Optimal Torque Settings For A Lathe Parting Tool When Working With Different Types Of Metals?When you use a lathe parting tool, the type of metal matters a lot. Softer metals need less torque, so it’s easier to cut. Harder metals require more torque because they are tougher. The tool’s sharpness also affects how much torque you need. Always adjust for the metal you’re using to get the best cut!

How Can Improper Torque Application Lead To Tool Wear Or Failure In A Metal Lathe’S Parting Process?Improper torque means not using the right tightness when fixing tools on a metal lathe. If you make it too tight, it can break the tool. If it’s too loose, the tool can wobble and wear out fast. Both ways can cause the tool to fail, making it harder to cut metal right. Always check to use the correct torque for best results!

What Types Of Lathe Parting Tools Are Best Suited For High-Torque Applications In Metal Machining?For high-torque metal machining, you should use strong parting tools made from carbide. These tools are very hard and stay sharp longer. They can cut through tough metals without breaking. You might also choose tools that have thicker blades for extra strength. Always pick the right tool to get the best results!

How Does The Diameter And Thickness Of The Workpiece Affect The Torque Requirements When Using A Parting Tool On A Metal Lathe?The diameter and thickness of the workpiece change how hard you have to push the tool. A thicker or wider piece requires more force to cut. This is because you need to remove more metal at once. So, the bigger the piece, the more torque, or turning force, you need. Keeping the tool sharp helps make cutting easier too!

What Are Some Best Practices For Adjusting And Measuring Torque On A Lathe Parting Tool To Ensure Precision And Efficiency In Machining?To get the best results when using a lathe parting tool, follow these steps. First, always start with the tool properly tightened. Use a torque wrench to check how tight it is. Make small adjustments to the torque, so the tool cuts smoothly. Lastly, regularly measure how well the tool is working and adjust as needed. This keeps everything precise and saves time!