Have you ever wondered how much power your metal lathe really needs? Understanding lathe power requirements is crucial for anyone working with these machines. The way a lathe operates relies on its motor and belt system. A strong and reliable belt plays a big part in this.

Imagine you’re in a workshop, shaping a metal part. Suddenly, your lathe stops working. Frustrating, right? This often happens due to insufficient power or a worn-out belt. Knowing how to calculate the needed power can save you time and headaches.

Here’s a fun fact: Did you know that an underpowered lathe can lead to poor work quality? The belt transfers energy from the motor to the cutting tool. If it’s too loose or old, the machine cannot perform well. This article will help you understand these power needs and make smart choices for your metal lathe.

Understanding Lathe Power Requirements For Metal Lathe Belt

Lathe Power Requirements: The Basics

Understanding lathe power requirements is essential for any metalworking project. The size and strength of your lathe’s motor must match the tasks you plan to accomplish. A powerful lathe allows for clean cuts and improved efficiency. Did you know that older lathes often use belts to transfer power? These belts need regular checks for wear. Proper tension keeps them running smoothly. Choosing the right belt affects performance significantly. So, what’s the right fit for your metal lathe?Understanding Lathe Power Requirements

Definition of lathe power requirements and importance in metalworking. Factors influencing power requirements in metal lathes.Lathe power requirements mean how much energy a lathe needs to work well. This is very important in metalworking. If a lathe doesn’t have enough power, it can’t cut metal properly. Some key factors that influence power needs include:

- Type of material being used

- Thickness of the metal

- Speed of the cutting process

- Size and design of the lathe

Understanding these points helps ensure you have the right machine for your projects.

What factors affect lathe power requirements?

Factors affecting lathe power include the material used, thickness of the workpiece, speed, and the lathe’s size and design. These details help you pick the right lathe for the job.

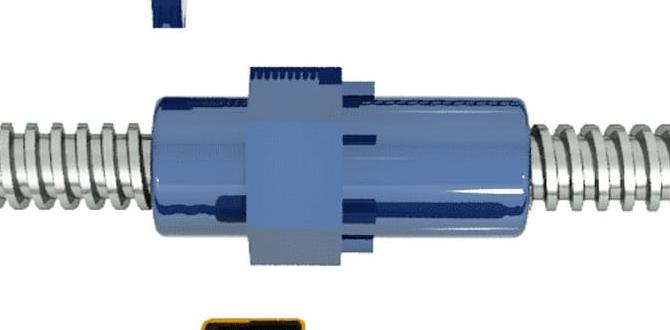

Belt Drives vs. Direct Drives

Explanation of belt drives and their role in lathe power transmission. Advantages and disadvantages of beltdriven systems compared to direct drive systems.When it comes to power transmission in lathes, belt drives are like the fun rollercoasters of the mechanical world! They use a belt to transfer power from the motor to the lathe. This system can be both flexible and efficient. However, it’s not all fun and games. One big advantage is that belt drives can easily handle different speeds. But, like that sneaky rollercoaster that gives you a slight jolt, they can also slip and wear out over time.

| Aspect | Belt Drives | Direct Drives |

|---|---|---|

| Flexibility | ✅ Easily change speeds | ❌ Fixed speed |

| Maintenance | 🔧 Need more upkeep | 👍 Lower maintenance |

| Efficiency | 😅 Can lose power through slipping | ⚡ More efficient |

In contrast, direct drives are straight to the point! They connect the motor directly to the lathe. While they offer more efficiency and less maintenance, they can be less versatile. Think of them as the dependable friend who always shows up on time but never wants to try anything new. Each option has its own quirks, so it’s important to pick the one that fits your needs best!

Calculating Power Requirements

Key formulas for calculating the power requirements of a lathe. Example calculations for different lathe operations.Power needs for a lathe can be found using simple formulas. A key formula is: Power (HP) = Torque (Nm) x RPM / 9.55. This helps you know how much power to expect. For example:

- For a lathe with 50 Nm torque and 600 RPM: Power = 50 x 600 / 9.55 ≈ 31.4 HP

- For 30 Nm torque and 1200 RPM: Power = 30 x 1200 / 9.55 ≈ 37.7 HP

These calculations guide you in selecting the right lathe for your tasks. Always check the power requirements to ensure smooth operations.

What formulas help calculate lathe power?

The main formula is Power (HP) = Torque (Nm) x RPM / 9.55. This helps find how much energy the lathe needs to run without strain.

Choosing the Right Belt for Your Lathe

Factors to consider when selecting a belt for optimal performance. Types of belts and their respective suitability for various lathes.Choosing the right belt for your lathe is essential for smooth operation. First, consider the belt width, as it affects power transfer. The belt type can vary, influencing performance. Some common types include:

- V-belts – Great for standard machines.

- Timing belts – Ideal for precision lathes.

- Flat belts – Good for larger lathes.

Remember to check the material of the belt, as this affects durability and efficiency. A suitable belt ensures optimal performance and longevity for your lathe.

What should I consider when choosing a lathe belt?

Pay attention to belt type, width, and material for best results.

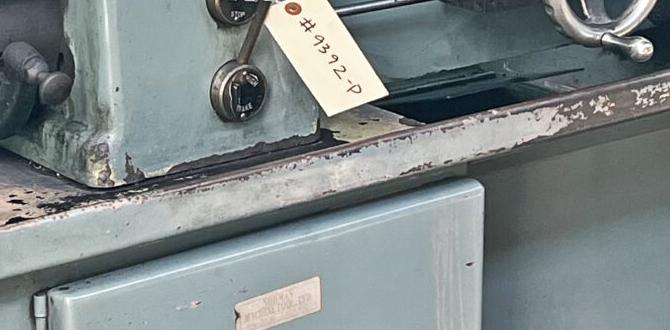

Maintenance of Lathe Belts

Best practices for maintaining lathe belts for longevity and efficiency. Signs of wear and when to replace lathe belts.Taking care of lathe belts is key for a smooth machine and happy workers. Regularly check for cracks, fraying, or signs of wear. If you notice any of these, it’s time for a new belt. A worn-out belt can slip, causing the machine to misbehave like a cat who refuses to move! To help you remember belt health, here’s a quick guide:

| Signs of Wear | Action Needed |

|---|---|

| Cracks or splits | Replace immediately! |

| Fraying edges | Time for a new belt! |

| Squeaking noise | Check tension |

Keeping your lathe belts in good shape helps your machine run better. Remember, a little care goes a long way!

Energy Efficiency and Cost Considerations

Analysis of power consumption in lathes and its impact on operating costs. Tips for improving energy efficiency in lathe operations.Understanding power use in lathes is key to saving money. A lathe can munch up electricity like a hungry hippo. By tracking power consumption, you can see how it affects your bills. Want to save on costs? Use energy-efficient motors and smart settings. They cut power use but keep the fun of turning metal! Remember, a little planning means less spending, and that’s a win-win!

| Tips for Energy Efficiency |

|---|

| Use energy-efficient motors |

| Optimize speeds and settings |

| Regular maintenance checks |

Common Misconceptions about Lathe Power Needs

Addressing common myths regarding lathe power requirements. Clarifying the importance of proper alignment and adjustments.Many people think they need a massive power supply to run a lathe. This idea is often way off! In reality, proper alignment and adjustments are the keys to success. If your belt isn’t snug, your lathe might not work well, even with a power-packed motor. Imagine trying to ride a bike with flat tires—it’s no fun! So, keep your lathe tuned, and it will run smoother than a cat on a sunny windowsill.

| Myth | Fact |

|---|---|

| More power means better performance. | Proper alignment matters more. |

| All lathes need the same power supply. | Power needs vary by model. |

Future Trends in Lathe Technology

Innovations in lathe technology and their implications for power requirements. Potential advancements in energyefficient models and designs.New lathe technology is changing how we make things. These machines are smarter and use less power. Innovations help in designing models that save energy. This means lower electricity bills and less waste. Energy-efficient lathes can help keep our planet green. This is important as we use machines more. In the future, we will see:

- Improved speed and accuracy

- Stronger and lighter materials

- Smart controls that save energy

How do energy-efficient lathes affect costs?

Energy-efficient lathes reduce operating costs by using less electricity. This saves money and benefits the environment. As these advances continue, we can expect even greater savings in time and resources.

Conclusion

In summary, understanding lathe power requirements is essential for effective metalwork. Choosing the right belt impacts machine efficiency and durability. Always check your lathe’s specifications before buying parts. This ensures safety and optimal performance. We encourage you to explore more about lathe maintenance and accessories. The more you learn, the better your projects will be!FAQs

Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Belts:Sure! A lathe is a machine that spins metal to shape it. To work well, a lathe needs enough power from its motor. The size of the motor affects how strong the lathe can be. Metal lathe belts help connect the motor to the lathe. These belts help transfer power so the lathe can spin and cut.

Sure! Just share the question you have in mind, and I’ll provide a simple answer.

What Factors Influence The Power Requirements For Operating A Metal Lathe?The power needed for a metal lathe depends on several things. First, the size and weight of the metal you’re cutting matter. Bigger pieces need more power. Second, the speed at which you spin the metal affects power use. Faster speeds require more energy. Lastly, the type of cutting tool you use can make a difference too. Some tools cut smoothly, while others need more power to work well.

How Do Different Belt Configurations Affect The Torque And Speed Output Of A Metal Lathe?Different belt configurations change how fast and strong a metal lathe works. If the belt is set to a lower speed, it gives more torque, which means it can cut metal better. For faster speeds, the torque is lower, but you can finish your work more quickly. You can switch belts to match what you need, like cutting soft or hard materials. It’s all about finding the right balance for your project.

What Are The Recommended Motor Sizes For Various Types Of Metal Lathes Based On Their Specifications?For small metal lathes, like hobby ones, you need about 1/2 to 1 horsepower. Medium lathes work best with 1 to 2 horsepower. Larger lathes, used in factories, often need 3 to 5 horsepower. The bigger the lathe, the more power it needs to cut metal easily. Always check the lathe’s manual for the best motor size.

How Can Belt Slippage Impact The Performance And Efficiency Of A Lathe?Belt slippage happens when the belt on the lathe doesn’t grip well. This makes the lathe work less efficiently. You might notice it runs slower or makes funny noises. If the belt slips, it can cause mistakes in the work. Overall, it makes the machine less useful and harder to control.

What Maintenance Practices Should Be Followed To Ensure Optimal Performance Of Lathe Belts And Motor Systems?To keep lathe belts and motor systems working well, you should check them often. Look for wear and tear on the belts. You should also keep them clean and free of dust or dirt. Tighten any loose parts, and make sure the motor is lubricated. If something is broken, fix it right away.