Have you ever wondered how a lathe works and what it needs to run well? Think of a lathe like a magic tool. It can shape metal into many forms. But to make those amazing shapes, it needs power. Understanding lathe power requirements is important for anyone who wants to use one.

Imagine trying to bake a cake without knowing how much flour to use. It just wouldn’t turn out right! The same goes for metal lathe maintenance. If you don’t keep it in good shape, you may not get the results you want. Regular care helps the lathe last longer and perform better.

Surprisingly, many people ignore these power needs and maintenance steps. They hope their lathe will just work. But that’s a risky gamble. Knowing your machine’s requirements can save you time and frustration. So, let’s dive into the world of lathe power and see how proper maintenance can keep your projects running smoothly.

Understanding Lathe Power Requirements And Metal Lathe Maintenance

Lathe Power Requirements and Maintenance

Understanding lathe power requirements is crucial for any metalworking enthusiast. A metal lathe needs the right voltage and amperage to operate smoothly. Regular maintenance increases the lathe’s lifespan and performance. Check belts, lubricate moving parts, and clean shavings to keep it in great shape. Did you know that a well-maintained lathe can reduce energy costs? Proper care ensures safe, efficient operation, letting you create with confidence. Always remember, a happy lathe means happy projects!Importance of Lathe Power Requirements

Explanation of power requirements for different types of metal lathes.. Factors affecting power consumption in lathe operations..Choosing the right power for your lathe is like picking the perfect pizza topping—it can make or break the experience! Different metal lathes have varying power needs, depending on their size and capabilities. For instance, a small lathe could run well on just 1-2 HP, while bigger beasts may require 10 HP or more. Remember, power consumption also depends on factors like speed, material type, and tool sharpness. Don’t be surprised if your lathe drinks up power like a thirsty cactus on a hot day!

| Lathe Type | Horsepower (HP) |

|---|---|

| Mini Lathe | 1-2 HP |

| Mid-Size Lathe | 3-5 HP |

| Large Lathe | 6-10 HP |

Determining the Right Power for Your Lathe

How to calculate the required horsepower for specific tasks.. Importance of matching power to material types and cutting conditions..Choosing the right power for your lathe is crucial. First, you need to calculate the horsepower required for the tasks you want to perform. This depends on what material you are cutting and the conditions you face. Harder materials need more power, while softer ones are okay with less. Always ensure your lathe matches the cutting tasks. It’s like using a tiny spoon to eat soup—you’ll be there all day! Here’s a handy table to help:

| Material Type | Recommended Horsepower |

|---|---|

| Soft Metals | 1-2 HP |

| Steel | 2-3 HP |

| Hard Metals | 3-5 HP |

By using the right horsepower for your materials, you’ll cut efficiently and keep your lathe happy. A well-powered lathe is a happy lathe—nobody wants a grumpy machine on their watch!

Common Power Issues in Metal Lathes

Identification of common powerrelated problems.. Troubleshooting tips for power inconsistencies..Power problems can stop a metal lathe from working well. Common issues include sudden stops, loud noises, and power surges. These can happen due to worn-out parts or loose connections. To fix these issues, follow these troubleshooting tips:

- Check the power source for stability.

- Inspect cables for damage or wear.

- Make sure all connections are tight.

- Look for worn-out motor or power switches.

Fixing these problems early can save time and money. Regular checks keep your lathe running smoothly.

What are the signs of power problems in metal lathes?

Signs include unexpected stops, unusual noises, and inconsistent speeds during operation.

Maintenance Practices for Metal Lathes

Daily, weekly, and monthly maintenance tasks to ensure efficiency.. Importance of lubrication and its impact on power requirements..Keeping your metal lathe in top shape is like feeding a pet—regular checks keep it happy and functional. Daily, check for chips and debris that can cause trouble. Weekly, spend time cleaning and tightening loose parts. Monthly, inspect belts and gears, making adjustments as needed. Don’t forget lubrication! Proper lubrication helps reduce wear and keeps power requirements low, making your machine hum instead of wheeze. Remember, a well-oiled lathe is a happy lathe!

| Maintenance Schedule | Tasks |

|---|---|

| Daily | Clear chips, check controls |

| Weekly | Clean, tighten loose parts |

| Monthly | Inspect belts, lubricate |

Electrical Considerations for Lathe Setup

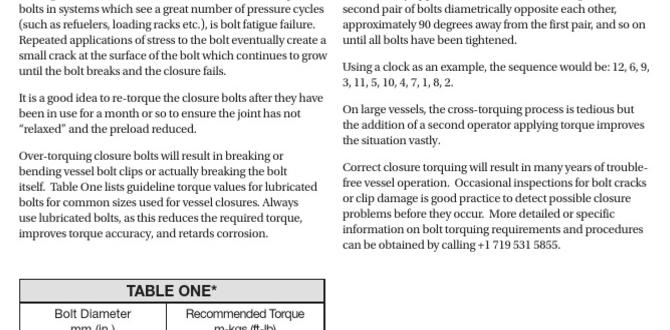

Essential electrical specifications for safe operation.. Impact of power supply variability on lathe performance..Setting up a lathe involves more than just turning it on and hoping for the best. First, you need to check the electrical specifications. Ensure the voltage matches your lathe’s requirements. Too much or too little power can lead to hiccups in performance—or worse, a big metal ball of doom!

Next, power supply variability can make your lathe feel like it’s on a rollercoaster. Sometimes it speeds up, and sometimes it stalls. This inconsistency can mess up your work. So, use a reliable power source. Your lathe—and your sanity—will thank you!

| Specification | Recommended Value |

|---|---|

| Voltage | 220-240 V |

| Current | 10-20 A |

| Phase | Single/Three |

Keeping these electrical points in check is key for smooth sailing—or should we say, smooth spinning?

Best Practices for Lathe Operation

Techniques to optimize power usage during operation.. How operational practices can prolong lathe lifespan and reduce maintenance needs..Using your lathe efficiently can save energy and extend its life. Simple changes can make a big impact! Optimizing power usage helps keep your machine happy. Here are tips to consider:

- Regularly clean your lathe to prevent dust buildup.

- Lubricate moving parts as recommended by the manufacturer.

- Adjust speed settings based on the material being worked on.

These practices reduce wear and tear, helping to keep maintenance needs low. Happy lathing!

Why optimize power usage on a lathe?

Optimizing power usage saves energy and extends the life of your lathe. It is important for both performance and cost savings. A well-maintained lathe works better for a longer time.

Upgrading Lathe Power Systems

Signs that indicate a need for power system upgrades.. Recommendations for modernizing outdated lathe power systems..Old lathe power systems can show signs they need upgrades. If you notice strange noises or the machine struggles when cutting, it’s time to act. Dim lights or power outages may also indicate problems. These issues can slow your work and cause accidents.

To modernize your lathe power system, consider these upgrades:

- Replace old motors with energy-efficient ones.

- Install a variable speed drive for better control.

- Upgrade wiring to handle more power safely.

- Add safety features like emergency stop buttons.

What are key signs for upgrading lathe power systems?

Look for strange noises, frequent power interruptions, or difficulty during operations. These are clear signs that it’s time to consider an upgrade.

Conclusion

In summary, understanding lathe power requirements helps you choose the right machine for your projects. Regular metal lathe maintenance keeps your tool running smoothly and extends its life. You can clean, lubricate, and check alignment to avoid issues. If you want to learn more, consider reading further or watching maintenance videos. Good care leads to better results!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Maintenance:Sure! Here are some answers about lathe power and maintenance. To run a lathe, you need to check its power needs. Each lathe needs a different amount of electricity. You should clean your lathe regularly to keep it working well. Check the parts for wear, and oil the moving parts to help them move smoothly. If something breaks, get it fixed right away so you can keep using the lathe safely.

Sure! Just give me the question you’d like me to answer, and I’ll be happy to help!

What Factors Determine The Power Requirements For Operating A Metal Lathe?To find out how much power a metal lathe needs, we think about a few things. First, the size of the lathe matters; bigger lathes need more power. Next, the type of metal you’re cutting makes a difference. Harder metals take more energy to cut. Lastly, how fast you want to work affects the power too; faster speeds need more power to run smoothly.

How Can Regular Maintenance Of A Lathe Improve Its Power Efficiency And Performance?Regular maintenance of a lathe helps keep it running smoothly. If we clean it and check for problems, it works better and uses less power. Changing oil and tightening parts helps it spin faster. This means our work can be done quicker and with less energy. Taking care of the lathe is like taking care of a bike; the better you care for it, the better it rides!

What Are The Signs That Indicate A Metal Lathe May Require Maintenance Or Repairs To Maintain Optimal Power Output?If your metal lathe makes strange noises, it may need repairs. You might see leaks or oil spots. The machine could feel extra hot while working. If it shakes or vibrates a lot, that’s a sign too. Keep an eye on these signs to keep it working well!

How Does The Type Of Material Being Machined Influence The Power Consumption Of A Lathe?Different materials need different amounts of power when using a lathe, which is a tool that shapes things like wood or metal. Hard materials, like steel, require more energy to cut than soft ones, like plastic or wood. This is because harder materials are tougher to slice through. If you choose a tough material, the lathe will use more power to do the job. So, what you are working with can change how much energy you need.

What Routine Maintenance Practices Should Be Performed To Ensure A Metal Lathe Operates Effectively And Retains Its Power Capabilities?To keep a metal lathe working well, you should clean it regularly. Remove dust and metal shavings after each use. Check and tighten any loose parts so everything stays safe. You should also oil the moving parts to help them work smoothly. Lastly, check the belts and change them if they look worn out.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Maintenance:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some answers about lathe power and maintenance. To run a lathe, you need to check its power needs. Each lathe needs a different amount of electricity. You should clean your lathe regularly to keep it working well. Check the parts for wear, and oil the moving parts to help them move smoothly. If something breaks, get it fixed right away so you can keep using the lathe safely.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question you’d like me to answer, and I’ll be happy to help!”}},{“@type”: “Question”,”name”: “What Factors Determine The Power Requirements For Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find out how much power a metal lathe needs, we think about a few things. First, the size of the lathe matters; bigger lathes need more power. Next, the type of metal you’re cutting makes a difference. Harder metals take more energy to cut. Lastly, how fast you want to work affects the power too; faster speeds need more power to run smoothly.”}},{“@type”: “Question”,”name”: “How Can Regular Maintenance Of A Lathe Improve Its Power Efficiency And Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regular maintenance of a lathe helps keep it running smoothly. If we clean it and check for problems, it works better and uses less power. Changing oil and tightening parts helps it spin faster. This means our work can be done quicker and with less energy. Taking care of the lathe is like taking care of a bike; the better you care for it, the better it rides!”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate A Metal Lathe May Require Maintenance Or Repairs To Maintain Optimal Power Output?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If your metal lathe makes strange noises, it may need repairs. You might see leaks or oil spots. The machine could feel extra hot while working. If it shakes or vibrates a lot, that’s a sign too. Keep an eye on these signs to keep it working well!”}},{“@type”: “Question”,”name”: “How Does The Type Of Material Being Machined Influence The Power Consumption Of A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials need different amounts of power when using a lathe, which is a tool that shapes things like wood or metal. Hard materials, like steel, require more energy to cut than soft ones, like plastic or wood. This is because harder materials are tougher to slice through. If you choose a tough material, the lathe will use more power to do the job. So, what you are working with can change how much energy you need.”}},{“@type”: “Question”,”name”: “What Routine Maintenance Practices Should Be Performed To Ensure A Metal Lathe Operates Effectively And Retains Its Power Capabilities?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, you should clean it regularly. Remove dust and metal shavings after each use. Check and tighten any loose parts so everything stays safe. You should also oil the moving parts to help them work smoothly. Lastly, check the belts and change them if they look worn out.”}}]}