Have you ever wondered how a metal lathe works? It’s a fascinating tool that shapes metal. But setting up a lathe isn’t just about having the right equipment. You also need to know its power requirements.

When starting a metal lathe setup, the right power supply is crucial. Too little power means your lathe won’t work well. Too much can damage it. Imagine trying to run a race with shoes that are either too big or too small. It just won’t work!

Many people overlook the importance of knowing their lathe’s needs. But understanding these power requirements can save you time and money. You want your projects to run smoothly, right?

In this article, we’ll explore how to set up your lathe properly. We’ll dive into what power your metal lathe needs. Get ready to discover some surprising tips! Your next metal project will be easier and more fun!

Lathe Power Requirements For Metal Lathe Setup Explained

Lathe Power Requirements and Setup

Setting up a metal lathe can be exciting but also tricky. Did you know that power requirements vary by model? Most lathes need a power supply between 110 to 240 volts. Understanding the right motor size is vital for smooth operation. You must also ensure your workspace has adequate power outlets. Ignoring these details can lead to annoying interruptions while working. Always check the manufacturer’s specifications for optimal performance. Happy turning!Understanding Lathe Power Requirements

Definition of power requirements for a lathe. Importance of selecting the right power for metalworking.Power requirements for a lathe refer to the energy needed to operate it efficiently. Choosing the right power is vital in metalworking. The correct power ensures smooth operation and better finishes on your projects. It helps prevent damaging the machine or your materials. Not having enough power can lead to poor performance.

- Improved results: You create cleaner cuts.

- Safety: Proper power reduces risks of accidents.

- Durability: Right power levels keep the machine in good shape.

Why is lathe power important?

Choosing the correct power affects your project quality. The right power allows the lathe to run smoothly.

Key Factors Influencing Power Needs

Material type and thickness considerations. Recommended speed and torque requirements.Choosing the right power for your lathe is like picking the right snack for a movie—too little and you’re bored, too much and you might explode! Material type and thickness play a big role in your power needs. Softer materials, like aluminum, need less power, while tougher metals like steel require a stronger setup. Make sure to check recommended speed and torque. Faster isn’t always better; you might end up with a spinning mess instead of a masterpiece!

| Material Type | Thickness | Speed (RPM) | Torque (Nm) |

|---|---|---|---|

| Aluminum | Thin | 1200 | 5 |

| Steel | Medium | 600 | 15 |

| Stainless Steel | Thick | 300 | 25 |

Stay aware of these factors for a smooth machining experience, or risk becoming the next lathe meme!

Calculating Power Requirements for a Metal Lathe

Formula to calculate horsepower and torque. Examples of calculations based on different setups.Understanding how to determine the power needed for a metal lathe is key for smooth machining. The horsepower (HP) needed can be calculated using the formula: HP = (Torque x RPM) / 5252. Torque is usually measured in foot-pounds. Let’s see how this formula works with some setups.

| Setup | Torque (ft-lbs) | RPM | Horsepower |

|---|---|---|---|

| Small Lathe | 10 | 300 | 0.57 |

| Medium Lathe | 30 | 200 | 1.14 |

| Large Lathe | 50 | 150 | 2.38 |

As you can see, power requirements change based on the setup. A small lathe might need less oomph than a big one, just like a calorie-filled cake needs more energy than a lettuce leaf. Knowing this helps you get the right motor for your projects!

Setting Up Your Metal Lathe for Optimal Performance

Stepbystep setup of power supply. Safety precautions to consider during setup.Once you have your metal lathe ready, setting it up for power is key. Begin by connecting the power supply with a strong cord—think of it as your lathe’s spaghetti for energy! Make sure all the plugs fit snugly to avoid shocking surprises. Safety is super important; keep a fire extinguisher nearby, just in case your lathe decides to throw a tantrum. Here’s a quick table for a safe setup:

| Step | Action |

|---|---|

| 1 | Check your power source |

| 2 | Use proper cables |

| 3 | Keep the area clear |

| 4 | Wear safety gear |

Remember, good setup leads to great performance. Your lathe should be ready to spin magic and not cause chaos. Happy lathe-ing!

Troubleshooting Power Issues in Lathe Operations

Common powerrelated problems in lathe operations. Solutions and preventive measures to avoid power issues.Power problems in lathe operations can be a real pain. A common issue is low voltage, which may cause the machine to stall. Always check your power source first! If the motor is making odd noises, it might be time for some maintenance. The best solution? Regular checks and cleanups. Preventive measures, like using surge protectors, can save you from future headaches. Here’s a table with quick fixes:

| Problem | Solution |

|---|---|

| Low Voltage | Check power source |

| Strange Noises | Regular maintenance |

| Frequent Stalls | Use surge protectors |

So remember, a happy lathe makes for a happy operator! And just like humans, machines need their regular check-ups to stay in good shape.

Maintaining Power Efficiency in Metal Lathes

Tips for maintaining energy efficiency. Importance of regular maintenance to ensure power efficiency.Keeping your metal lathe power-efficient is important. Here are some simple tips:

- Regularly check for loose parts.

- Clean the machine to prevent dust buildup.

- Use the right tools to avoid strain.

- Keep the workspace organized for better flow.

Regular maintenance helps your lathe run smoothly. It can save energy and prevent costly repairs. A well-maintained lathe can use up to 30% less energy than a neglected one. This saves you money on electricity!

How often should I maintain my metal lathe?

You should inspect your lathe every month and give it a thorough cleaning every three months to ensure efficiency and performance.

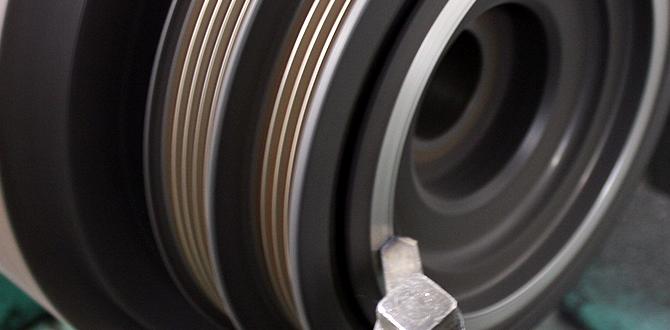

Choosing the Right Motor for Your Lathe

Factors to consider when selecting a motor. Comparison of motor options available in the market.Finding the right motor for your lathe can feel like shopping for the best pizza in town—there are so many choices! Start by considering power requirements. A motor’s horsepower must match your lathe’s needs. Look at motor types like AC and DC. AC motors are usually cheaper, while DC motors offer more control. Both have advantages, depending on your projects. Check out this handy comparison:

| Motor Type | Advantages | Disadvantages |

|---|---|---|

| AC Motor | Cost-effective, reliable | Less control over speed |

| DC Motor | Precise speed control | Generally more expensive |

Consider your projects. If you need speed, go DC. If you want a bargain, AC is the way. Remember, the right motor can turn your lathe into a powerful tool, much like a superhero cape! Choose wisely, and you’ll be on your way to metalworking greatness.

Conclusion

In conclusion, understanding lathe power requirements is key to a successful metal lathe setup. You need to know the motor size and power needs for your projects. Always check your machine’s manual for guidance. We recommend researching different lathe models and their specifications. This helps you make informed choices and start working confidently. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Setup:A lathe is a machine that helps you shape metal. To power it, you usually need electricity. The amount of power needed depends on the size of the lathe. You also need to set it up safely so it works well. Always check the instructions first before starting!

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help!

What Factors Should Be Considered When Calculating The Power Requirements For A Metal Lathe Setup?When figuring out how much power a metal lathe needs, think about a few key things. First, look at the size of the lathe. Bigger lathes usually need more power. Next, consider the materials you will work with. Harder metals need more energy to cut. Finally, check the speed settings. Faster speeds might need extra power.

How Do Different Materials Being Machined Affect The Power Needed For A Lathe Operation?When you use a lathe, the material you work with changes how much power you need. Softer materials, like plastic or aluminum, require less power. Harder materials, like steel or titanium, need more power to cut through them. This happens because tougher materials resist the cutting tool more. So, we adjust the machine’s power based on what we’re working on.

What Is The Role Of Spindle Speed And Torque In Determining The Power Requirements For A Lathe?Spindle speed is how fast the lathe’s spinning part goes. Torque is the turning force it has. Together, they help us know how much power the lathe needs to work well. If the spindle spins faster or has more torque, it needs more power. So, we must balance speed and torque to use the right amount of power for each job.

How Do The Size And Capabilities Of A Metal Lathe Influence The Electrical Supply Specifications Needed For Setup?The size of a metal lathe affects how much power it needs. Bigger lathes usually require more electricity to work properly. They have stronger motors that help them cut metal better. So, you need to make sure your electrical supply can give enough power for the lathe you choose. If it doesn’t, the lathe might not work well or could break.

What Are The Common Power Sources Used For Metal Lathes, And How Do They Differ In Terms Of Efficiency And Suitability For Various Machining Tasks?Metal lathes usually use either electric motors or hydraulic systems for power. Electric motors are common because they are efficient and easy to control. They work well for most tasks since you can adjust the speed easily. Hydraulic systems use fluids to power the machine. They are strong but not always as efficient for lighter jobs.