Have you ever wondered how a metal lathe spins so smoothly? The answer lies in understanding lathe power requirements. Knowing about the metal lathe spindle and its needs can make all the difference in your projects.

Imagine a craftsman working late into the night. He needs his tools ready and powerful. What if his lathe lacked the right power? It would struggle, and that could ruin his work. A reliable spindle is the heart of the lathe, giving it the strength to cut through tough materials.

Here’s a fun fact: did you know that the right power can help a metal lathe last longer? A well-powered spindle can improve precision and save time. What builder wouldn’t want that? By learning more about lathe power requirements, you become better equipped to tackle your own metalworking challenges.

Lathe Power Requirements: Understanding Metal Lathe Spindle Needs

Lathe Power Requirements for Metal Lathe Spindle

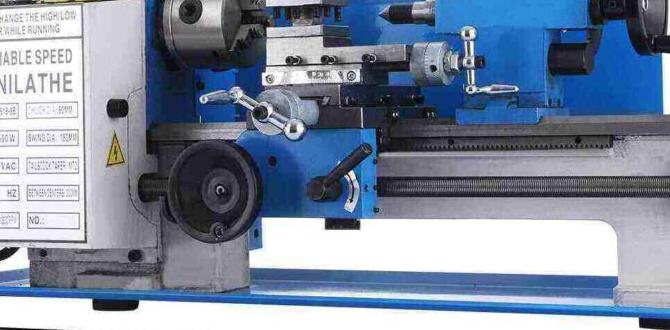

Understanding lathe power requirements is essential for metalworking. The spindle needs enough power to cut and shape materials accurately. A lathe’s horsepower affects its ability to handle different metals and cutting speeds. Have you ever wondered how a small motor can turn heavy metal? It’s all about the design and efficiency. When choosing a lathe, consider the spindle size and power needs. This ensures smooth operation and successful projects every time.What is a Metal Lathe Spindle?

Definition and purpose of a metal lathe spindle. Key components and their functions.A metal lathe spindle is a vital part of a lathe machine. It holds and rotates the material while it gets shaped. Think of it as a strong arm that spins things around. Key components include:

- Chuck: Holds the workpiece tightly in place.

- Bearings: Allow smooth rotation and support the spindle.

- Drive system: Provides power to turn the spindle quickly.

These parts work together so you can create precise shapes from metal or wood. A sturdy spindle helps makers craft better products!

Why is a metal lathe spindle important?

The metal lathe spindle is crucial because it affects the quality of the finished product. It helps machines work correctly and safely.

Importance of Power Requirements

How power affects spindle performance. The relationship between power and machining efficiency.Power is the superhero of spindle performance! Without the right power, it’s like trying to run a marathon in flip-flops—it just won’t work. A strong spindle needs enough power to spin fast and cut through metal smoothly. If it doesn’t get enough juice, machining becomes slow and messy, like trying to cut cake with a spoon. Proper power helps improve machining efficiency, letting you finish projects quicker and with less hassle!

| Power Level | Spindle Performance | Machining Efficiency |

|---|---|---|

| Low | Poor | Slow |

| Optimal | Great | Fast |

| High | Excellent | Super-Fast |

So, remember: Think of power like a pizza—more toppings (power) mean a better pizza party (performance). Keep your spindle powered up to keep the fun rolling!

Factors Influencing Power Requirements

Material type and its impact on power needs. Workpiece size and complexity considerations. Speed and feed rate requirements.Many things can change how much power a lathe needs. First, the material type plays a big role. Harder materials, like steel, demand more power than softer ones, like aluminum. Then, consider the size and shape of your workpiece. Larger or complex shapes need more effort. Finally, speed and feed rates matter too! Faster spinning means more power is needed. It’s like running a race; you use more energy sprinting than walking!

| Factor | Impact on Power Needs |

|---|---|

| Material Type | Harder materials need more power. |

| Workpiece Size | Larger pieces require extra energy. |

| Speed and Feed Rate | Higher speeds demand more power. |

Calculating Power Requirements for Metal Lathes

Basic equations and parameters used in calculations. Example scenarios with varying workloads.To figure out the power needs of a metal lathe, you can use simple equations. The most important factors are speed, torque, and efficiency. For example, if a lathe runs at 500 RPM with a torque of 2 Nm, you can use the formula: Power = Torque x Speed. Here are basic types of workloads:

- Light Work: Minimal force is needed; low power is enough.

- Medium Work: Requires balanced power and efficiency.

- Heavy Work: High power needed to handle tough materials.

Using the right calculations can ensure your lathe works smoothly without overloading it.

What power do you need for a metal lathe?

For a metal lathe, power can range from 1 HP for light tasks to over 10 HP for heavy work. This depends on the materials used and the tasks performed.

Selecting the Right Motor for Your Lathe Spindle

Types of motors suitable for metal lathe spindles. Matching motor power to spindle requirements.Choosing the best motor for your lathe spindle is essential. There are different types you can use. Common options include AC motors, DC motors, and stepper motors. Each type has unique strengths. You must also match the motor’s power with your spindle’s needs. This ensures effective and safe operation. Here’s a quick look:

- AC Motors: Great for constant speed.

- DC Motors: Perfect for variable speed control.

- Stepper Motors: Best for precise movements.

Make sure the motor’s power aligns with the spindle’s requirements. This will help you get the best performance from your lathe.

What is the best motor for a lathe spindle?

The best motor for a lathe spindle depends on your needs. If you need variable speed, choose a DC motor. For constant speed, consider an AC motor. For high precision, opt for a stepper motor.

Common Mistakes in Estimating Power Requirements

Overlooking load calculations. Ignoring manufacturer specifications.Estimating power requirements can feel like a puzzle. One common mistake is overlooking load calculations. Not considering how much weight your lathe will handle is like trying to lift an elephant after only training with a kitten! Another blunder is ignoring manufacturer specifications. Each machine is like a snowflake—unique! Skipping this info can lead to mismatched power needs. Let’s keep our lathes running smoothly and avoid these pitiful pitfalls!

| Error | Why It Matters |

|---|---|

| Overlooking load calculations | Can damage the lathe and create safety risks |

| Ignoring manufacturer specifications | Results in poor performance and higher costs |

Consequences of Inadequate Power Supply

Performance issues and reduced productivity. Potential damage to the lathe and workpieces.Using the wrong power supply for your lathe can lead to big problems. First, it can cause performance issues. The lathe may run slower, making your projects take forever. Imagine waiting for a turtle to finish a race! Second, this can hurt both the lathe and your workpieces. If the power is too low, you risk damaging them. Think of your lathe as a dog; it needs enough energy to fetch those tools. A weak supply can cause a real mess!

| Consequences | Effects |

|---|---|

| Performance Issues | Slower operations |

| Reduced Productivity | More time spent on tasks |

| Potential Damage | Harmed lathe and workpieces |

Future Trends in Lathe Power Requirements

Advancements in technology affecting power needs. Emerging trends in energy efficiency and sustainability.As technology improves, lathe power needs are changing fast. New machines are becoming smarter and need less energy, like magic spells for metal! And guess what? Many are now built to use power more wisely, reducing waste. This shift helps us save energy and protect our planet. Plus, using renewable energy sources can make our lathes not just powerful, but green too! Who knew that turning metal could be this cool?

| Trend | Description |

|---|---|

| Smart Technology | Machines that learn and adapt to tasks. |

| Energy Efficiency | Using less power for the same job. |

| Sustainability | Focus on using renewable energy. |

Conclusion

In conclusion, understanding lathe power requirements is crucial for using a metal lathe effectively. We learned that the spindle’s horsepower affects its performance and the materials it can handle. You should consider these factors when choosing a lathe. For deeper insights, check out guides on spindle specifications or join forums to discuss with other users. Happy machining!FAQs

What Factors Determine The Power Requirements For A Metal Lathe Spindle?The power needs for a metal lathe spindle depend on a few key factors. First, the size of the metal piece you are working on matters. Bigger pieces need more power. Second, how fast you want the spindle to spin affects power too. Lastly, the material type, like steel or aluminum, can change how much power you need.

How Do Spindle Speed And Material Types Affect The Power Consumption Of A Lathe?The spindle speed is how fast the lathe spins. If you turn the spindle faster, it uses more power. Different materials need different speeds too. Hard materials like metal require more power, while soft ones, like wood, need less. So, faster speeds and harder materials use more energy on a lathe.

What Is The Relationship Between Horsepower And Torque In A Metal Lathe Spindle?Horsepower and torque are important for a metal lathe spindle. Torque is how much force the spindle uses to turn, and horsepower shows how fast it can do that. When you have more torque, you can do tougher jobs. But if you want to work faster, you need more horsepower. They work together to help the lathe cut metal in different ways.

How Can An Operator Calculate The Ideal Power Requirements For Specific Machining Tasks On A Lathe?To find the right power for a lathe job, you start by knowing your material. Next, you check the size of the part you want to make. You can use a simple formula that combines the cutting speed, feed rate, and depth of cut. This helps you see how much power you need. Finally, you can adjust the machine settings to match these calculations for best results.

What Are The Common Electrical Requirements For Powering Different Sizes And Types Of Metal Lathe Spindles?To power metal lathe spindles, we need electricity. Smaller lathes might use around 110 volts, while larger ones often need 220 volts. The amount of power measured in horsepower (HP) can vary too; small lathes use 1 to 2 HP, while big ones need 3 HP or more. Always check the instructions for your specific lathe to know its power needs.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Factors Determine The Power Requirements For A Metal Lathe Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The power needs for a metal lathe spindle depend on a few key factors. First, the size of the metal piece you are working on matters. Bigger pieces need more power. Second, how fast you want the spindle to spin affects power too. Lastly, the material type, like steel or aluminum, can change how much power you need.”}},{“@type”: “Question”,”name”: “How Do Spindle Speed And Material Types Affect The Power Consumption Of A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The spindle speed is how fast the lathe spins. If you turn the spindle faster, it uses more power. Different materials need different speeds too. Hard materials like metal require more power, while soft ones, like wood, need less. So, faster speeds and harder materials use more energy on a lathe.”}},{“@type”: “Question”,”name”: “What Is The Relationship Between Horsepower And Torque In A Metal Lathe Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Horsepower and torque are important for a metal lathe spindle. Torque is how much force the spindle uses to turn, and horsepower shows how fast it can do that. When you have more torque, you can do tougher jobs. But if you want to work faster, you need more horsepower. They work together to help the lathe cut metal in different ways.”}},{“@type”: “Question”,”name”: “How Can An Operator Calculate The Ideal Power Requirements For Specific Machining Tasks On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right power for a lathe job, you start by knowing your material. Next, you check the size of the part you want to make. You can use a simple formula that combines the cutting speed, feed rate, and depth of cut. This helps you see how much power you need. Finally, you can adjust the machine settings to match these calculations for best results.”}},{“@type”: “Question”,”name”: “What Are The Common Electrical Requirements For Powering Different Sizes And Types Of Metal Lathe Spindles?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To power metal lathe spindles, we need electricity. Smaller lathes might use around 110 volts, while larger ones often need 220 volts. The amount of power measured in horsepower (HP) can vary too; small lathes use 1 to 2 HP, while big ones need 3 HP or more. Always check the instructions for your specific lathe to know its power needs.”}}]}