Have you ever wondered what makes a metal lathe work? It’s not just the tools. It’s also about the lathe power requirements. Understanding these needs is crucial for anyone interested in machining.

Imagine making a perfect piece of metal for a project. You pick up your lathe tools, but something doesn’t seem right. If the power supply isn’t enough, your project might fail. This can be frustrating!

Here’s a fun fact: many people don’t know that different lathes need different amounts of power. Some lathes are small and need less power, while others are big and mighty. Choosing the right power is key to success.

In this article, we will explore lathe power requirements. You’ll learn how to pick the right tools and ensure your lathe runs smoothly. Ready to discover more? Let’s dive in!

Understanding Lathe Power Requirements For Metal Lathe Tools

Lathe Power Requirements for Metal Lathe Tools

When choosing metal lathe tools, understanding lathe power requirements is crucial. The power needs depend on the size and type of the lathe. Smaller lathes often require less horsepower, while large machines need more to work efficiently. Have you ever wondered what happens if a lathe doesn’t have enough power? It might stall or produce poor quality work. Knowing these requirements helps you select the right tools for your projects. Power matters for smooth, accurate machining!What is a Lathe?

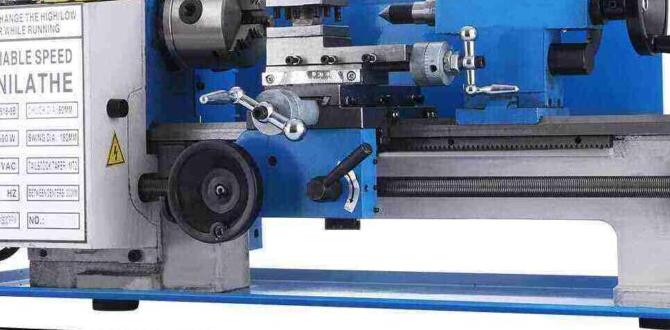

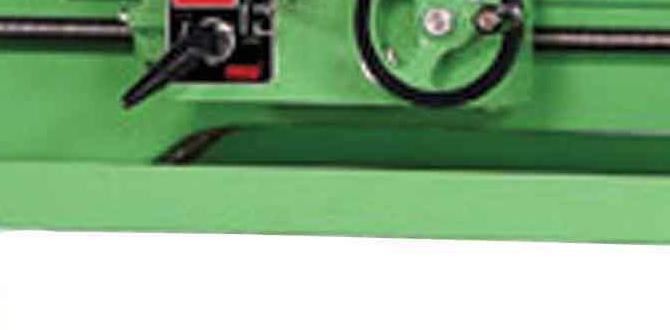

Definition and purpose of a lathe in machining.. Types of lathes and their applications in metalworking..A lathe is a machine tool used to shape metal and other materials. It works by rotating the material against a cutting tool. This helps create smooth shapes, like cylinders and cones. Different types of lathes are used in metalworking. They are classified mainly as:

- Engine Lathes: General-purpose tools for making various parts.

- Turret Lathes: Used for mass production with quick tool changes.

- CNC Lathes: Computer-controlled for precision and automation.

- Bench Lathes: Small lathes for light work and hobby projects.

Each type serves a specific purpose, helping to make various items, from gears to decorative pieces.

What can lathes do?

Lathes can cut, drill, and shape materials like metal, wood, and plastic! They help people create everything from simple tools to complex engine parts.

Understanding Power Requirements

Explanation of horsepower (HP) and torque in relation to lathes.. Factors that influence power requirements (material type, size of the project, etc.)..Horsepower (HP) measures the power of a metal lathe. It shows how much work it can do quickly. Torque is about the force that helps turn objects. Both are important for cutting metal smoothly.

Several factors affect a lathe’s power needs:

- Material type: Hard metals need more power.

- Size of the project: Larger projects require more strength.

- Speed settings: Higher speeds can also increase power demand.

Understanding these factors helps choose the right lathe for any task.

What is the difference between horsepower and torque?

The difference is important. Horsepower measures speed, while torque measures strength. Both are needed for effective cutting in machining.

What factors can affect power requirements?

- Material thickness

- Project complexity

- Desired finish quality

All these can change how much power your lathe will need.

Calculating Power Needs for Metal Lathes

Formulae for determining appropriate power levels.. Examples of calculations based on different metalworking tasks..Understanding power needs for metal lathes can seem tricky, but it’s like trying to find the right size pizza—too small, and you’re left hungry; too big, and it’s a waste! To figure out power levels, use this formula: Power (HP) = Torque (ft-lb) x RPM / 5252. For instance, if you need to cut steel with a lathe at 1000 RPM using 20 ft-lb of torque, you’ll need about 4 HP. Here’s a handy table to help you visualize different tasks:

| Task | Torque (ft-lb) | RPM | Power Required (HP) |

|---|---|---|---|

| Turning Aluminum | 10 | 1200 | 2.39 |

| Facing Steel | 15 | 800 | 3.79 |

| Drilling Brass | 5 | 1500 | 1.45 |

Remember, choosing the right power keeps your lathe chugging along smoothly, like a train on the right tracks! So, always double-check your numbers before you start crafting those shiny metal masterpieces.

Choosing the Right Lathe Motor

Types of motors (AC, DC) and their advantages.. Factors to consider when selecting a motor for a metal lathe..Picking the right motor is key for a lathe. There are two main types of motors: AC and DC. AC motors are strong and good for steady speed. DC motors are flexible and great for changing speeds easily. Think about these factors when choosing:

- Power needed for your projects.

- Space available for the motor.

- How often you will use the lathe.

Choose wisely for the best results!

What is the best motor for a metal lathe?

The best motor depends on your needs. A high-torque AC motor is perfect for heavy work, while a versatile DC motor suits different speeds. Consider your projects carefully!

Impact of Power Supply on Lathe Performance

Examination of singlephase vs. threephase power systems.. Issues related to power supply consistency and reliability..Powering a lathe properly is key for its smooth operation. Different power systems affect performance. Single-phase systems are easier to set up but can struggle with heavy loads. In contrast, three-phase systems give more power and stability, making them great for hard work.

Furthermore, consistent power is crucial. Fluctuations can harm the lathe and cause poor finishes. Reliability matters too; a steady power supply leads to better results.

- Single-phase: simple but limited power

- Three-phase: strong and stable for heavy tasks

- Consistent power prevents damage

Why is a stable power supply important?

A stable power supply enhances lathe precision, reduces wear, and improves overall quality.Maintenance of Lathe Power Systems

Tips on maintaining the motor and electrical components.. Signs of power system issues and troubleshooting tips..Keeping your lathe power systems humming is like keeping a pet goldfish happy. Feed it well and it thrives! First, regularly inspect the motor and electrical parts for dust and wear. A clean motor is a happy motor. Watch for signs like strange noises or flickering lights. These may say, “Help me!” If you spot issues, consult a pro right away. A stitch in time saves nine, and your lathe will continue to spin smoothly!

| Sign of Issue | Troubleshooting Tip |

|---|---|

| Strange noises | Check for loose parts |

| Power flickers | Inspect electrical connections |

| Motor overheating | Ensure proper ventilation |

Conclusion

In conclusion, understanding lathe power requirements is essential for using metal lathe tools effectively. Always match your lathe’s power to your projects. Check power ratings before buying tools. This ensures safety and efficiency. We encourage you to explore more about lathe specifications. Remember, the right tools lead to better results in your metalworking journey. Happy crafting!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Power Requirements And Metal Lathe Tools:Sure! A lathe is a machine that makes parts by spinning them. To know how much power it needs, you check the size and type of the job. Larger jobs usually need more power. Also, the tools you use can change how much power you need. A good tool helps the lathe work better and easier!

Sure! Please give me the question you’d like answered.

What Factors Determine The Power Requirements For Different Sizes Of Metal Lathes?The power needed for metal lathes depends on their size and what they’re doing. Bigger lathes usually need more power because they work with larger pieces of metal. The type of metal also matters; hard metals require more power to cut. Lastly, the speed at which you want to work will affect the power needed too.

How Does The Material Being Machined Affect The Power Consumption Of A Metal Lathe?The material we use on a metal lathe can change how much power it needs. Hard materials, like steel, require more power to cut. This means the machine works harder and uses more electricity. Softer materials, like aluminum, are easier to cut, so they need less power. Choosing the right material helps save energy while we work!

What Is The Significance Of Torque In Relation To The Power Needed For Various Lathe Operations?Torque is how strong the turning force is on a lathe machine. When you work on wood or metal, you need enough torque to cut through the material. More torque means it can handle tougher jobs without slowing down. So, when you know the torque, you can decide how much power you need for different tasks. This helps you do everything safely and nicely!

How Do Variable Speed Drives Influence The Power Requirements Of Metal Lathe Tools?Variable speed drives help metal lathe tools change their speed easily. When we adjust the speed, we can use just the right amount of power. This means tools can work better and use less energy. We can also avoid wasting power when cutting different materials. Overall, variable speed drives make our tools more efficient and save energy.

What Are The Consequences Of Using An Underpowered Lathe For Machining Tasks, And How Can This Be Mitigated?Using an underpowered lathe can cause problems like slow cutting and rough surfaces. It may also make the machine overheat. This can lead to mistakes or damage to the project. To help, you can take lighter cuts, use sharper tools, or choose a stronger lathe for tough jobs. Keeping the machine clean and well-oiled can also help it run better.