Upgrading your metal lathe can be exciting. But, have you considered the power it needs? Many people overlook the lathe power requirements. This can lead to problems later on. Imagine turning a perfect piece, only to find your lathe can’t handle it.

It’s not just about getting a fancy machine. You need to know if your current setup can support the changes. Many lathes will need more power for better performance. Can yours adapt? You want to avoid a costly mistake.

Here’s a fun fact: some lathes use less power but make amazing cuts. This shows that needing more power does not always mean better results. Let’s dive in and find out how to upgrade your metal lathe the smart way! You’ll learn about power requirements that get great results without breaking the bank.

Lathe Power Requirements For Your Metal Lathe Upgrade

Lathe Power Requirements for a Metal Lathe Upgrade

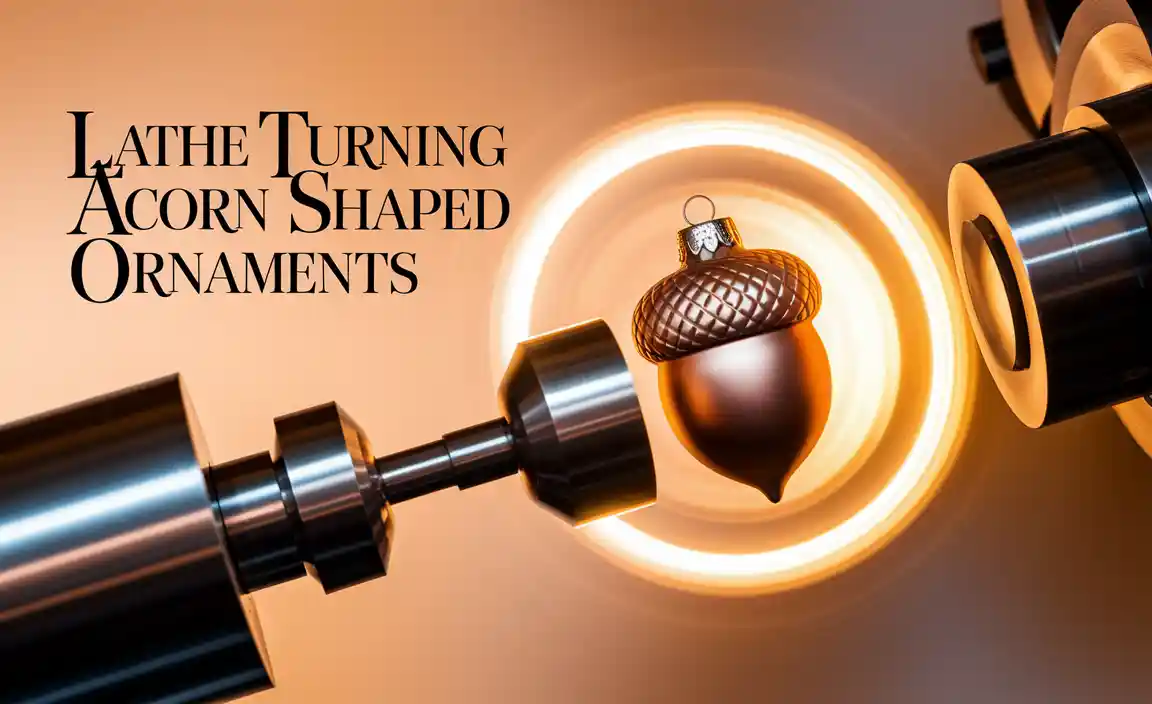

Upgrading your metal lathe? Understanding the power requirements is key. The size and type of your lathe determine the motor needed. Larger lathes may need more horsepower to handle heavy materials. Did you know that using the wrong power can cause damage? It’s important to check voltage and wattage compatibility too! Upgrading can improve efficiency and precision, making your work smoother. A careful choice in power boosts your lathe’s performance and longevity.Assessing Current Lathe Power Specifications

Key specifications to evaluate on existing machines. Common power rating measurements and their significance.Before upgrading your lathe, it’s like checking if your trusty old bike has enough gears for a hill climb. Start by looking at power ratings. These show how much energy your machine needs to spin metal smoothly. Typically, power is measured in horsepower (HP) or watts, like how fast a cheetah can run!

Another point to note is the torque, which tells you how hard the lathe can turn. More torque means challenging metal pieces won’t slow you down. Check the RPM too; it shows how many times your lathe can spin in a minute. Higher RPM means quicker cutting, like eating pizza before a game!

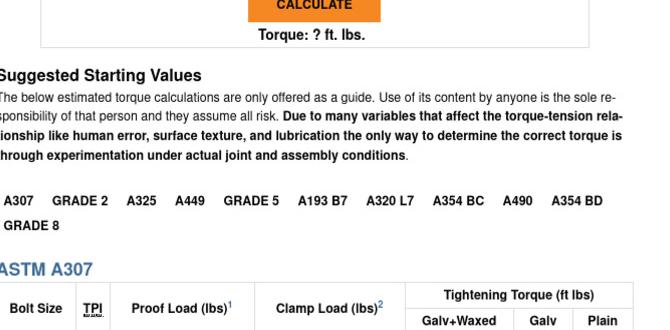

| Specification | Unit | Importance |

|---|---|---|

| Power Rating | HP/W | Indicates power efficiency |

| Torque | Nm | Determines cutting ability |

| RPM | Rev/min | Affects cutting speed |

Assessing these specifications is crucial. It ensures your upgrade meets your metal-spinning dreams without too many hiccups!

Identifying Your Machining Needs

Analyzing the types of materials commonly used. Understanding the complexity of projects to determine power needs.Choosing the right lathe starts with understanding what you’ll make. Different materials, like wood, aluminum, and steel, all need different power. More complex projects? They need more juice! Imagine trying to slice a birthday cake with a baseball bat. It won’t work, right? Your machine needs to match the task. Check out this handy table for a quick guide:

| Material | Power Requirement (HP) |

|---|---|

| Wood | 1-2 HP |

| Aluminum | 2-3 HP |

| Steel | 3-5 HP |

Getting your power right means smoother projects and less chance of a surprise “lathe vs. project” accident! Happy turning!

Calculating Required Power for Upgrades

Formulae to estimate power needs based on workload. Factors influencing power requirements such as speed and tool type.When upgrading a metal lathe, calculating the power needed is essential. A simple way to estimate power is by using the formula: Power (HP) = (Cutting Speed x Torque) / 33,000. Your workload affects this power. Factors to consider include:

- Speed: Faster speeds require more power.

- Tool Type: Different tools can change power needs.

Understanding these factors helps you choose the right lathe for your work.

What is the best way to calculate power for a metal lathe?

The best way is to use the formula: Power (HP) = (Cutting Speed x Torque) / 33,000. This gives a good estimate of needed power based on what you plan to do.

Choosing the Right Motor for Your Upgrade

Types of motors suitable for metal lathes. Pros and cons of various motor configurations.Picking a motor for your metal lathe can feel like choosing a pet — you want one that’s just right! Different motor types have their own quirks. For instance, DC motors offer great speed control but might not handle heavy jobs well. On the flip side, AC motors are like workaholics; they can tackle tough tasks but may need a bit more setup. Let’s look at a quick comparison:

| Motor Type | Pros | Cons |

|---|---|---|

| DC Motor | Good speed control, simple | Not great for heavy use |

| AC Motor | Strong, durable | Setup can be tricky |

Each choice has its charm and challenges. Think about your needs! And remember, a good motor should make your lathe hum like a happy cat, not roar like a lion!

Evaluating Power Supply Considerations

Identifying the necessary electrical supply for upgraded motors. Considerations for electrical safety and compliance.Upgrading your lathe’s motor can mean more power is needed. You must check your electrical supply first. Make sure it meets required voltage. This ensures your motor runs safely and efficiently. Safety matters too. Follow guidelines for electrical safety to avoid accidents.

- Check voltage and amperage requirements.

- Use proper wire sizes for safety.

- Confirm proper grounding.

- Follow local electrical codes.

What should I check for motor upgrades?

You should check the voltage, amperage, and wiring of your electrical supply to ensure it meets the motor’s needs.Cost-Benefit Analysis of Upgrading Lathe Power

Calculating potential productivity increases with upgraded power. Evaluating the longterm return on investment for upgrades.Thinking of upgrading your lathe can make a big difference. More power means better speed and performance. With upgrades, you can make more items in less time. This boosts your productivity and keeps customers happy.

To see if upgrades are worth the cost, consider:

- Increased production rates: More power leads to faster work.

- Long-term savings: Faster machines can save you money on labor.

In the long run, an upgrade can pay for itself. A recent study showed that businesses saw up to a 30% rise in output after upgrading their machines. Investing wisely can lead to brighter days ahead!

What are the benefits of upgrading lathe power?

Upgrading lathe power improves speed and productivity. You can complete more tasks in less time. This efficiency can lead to greater profit over the years.

Installation Considerations for Upgraded Power Systems

Tips for safe and effective motor installation. Compatibility of new components with existing lathe systems.Upgrading your lathe’s motor requires careful planning. First, make sure your new motor can fit where the old one was. It’s important that all parts work together. Follow these tips for a safe installation:

- Always turn off power before starting.

- Check that the voltage matches your machine’s needs.

- Use the right tools to prevent accidents.

- Consult the manual for specific instructions.

Taking these steps helps avoid damage and keeps you safe!

What are common installation mistakes to avoid?

Common mistakes include connecting wires incorrectly, ignoring weight limits, and not checking for part compatibility. Ensuring everything works together will improve your lathe’s performance.

Common Challenges and Solutions in Upgrading Power

Typical issues faced during power upgrades. Troubleshooting tips and best practices for new installations.Power upgrades to metal lathes can be tricky. Common issues include mismatched voltage and inadequate wiring. Here are some solutions and tips:

- Check your power source. Ensure it matches the lathe’s needs.

- Use thicker wires for safety and better performance.

- Consult the manual for installation guidelines.

- Test the system before fully operating it.

These steps can help avoid problems and ensure smooth upgrades.

What are common challenges with power upgrades?

Common challenges include incorrect voltage settings and poor wiring connections. Proper testing and using suitable materials can prevent these issues.

Maintaining Power Efficiency Post-Upgrade

Guidelines for optimizing performance after the upgrade. Regular maintenance tips to sustain power efficiency and performance.Upgrading your metal lathe can make a big difference. To keep it running smoothly, follow some simple guidelines. First, regularly check the oil. Fresh oil keeps parts happy. Next, clean your lathe often. Dust is like a party crasher! You don’t want it ruining your fun. Also, remember to tighten screws and bolts. Loose parts can lead to big problems. Lastly, consider a checklist to track maintenance—like a birthday list, but for your machine! You can find one below:

| Maintenance Task | Frequency |

|---|---|

| Check oil levels | Weekly |

| Clean surfaces | Every use |

| Tighten screws and bolts | Monthly |

| Inspect belts and wires | Every 6 months |

Conclusion

In conclusion, understanding lathe power requirements is crucial for a successful metal lathe upgrade. You need to match your machine’s motor with the tasks you plan to do. Consider the materials you will work with and the lathe’s features. To get the best performance, research different models and read reviews. You’re now ready to explore options for your upgrade!FAQs

What Factors Should Be Considered When Determining The Power Requirements For A Metal Lathe Upgrade?When figuring out the power needs for a metal lathe upgrade, think about the size of the projects you’ll do. Larger projects need more power. Also, consider the type of materials you’ll use. Harder materials usually require more power too. Finally, check your current power supply to make sure it can handle the new lathe.

How Does Motor Horsepower Affect The Performance And Cutting Capabilities Of A Metal Lathe?Motor horsepower (HP) tells us how strong the lathe’s motor is. A higher HP means the lathe can cut tougher metals more easily. With more power, the lathe can work faster and make smoother cuts. If you have a low HP, the lathe might slow down or not work well with thick materials. So, more horsepower helps you do better and faster work!

What Types Of Drive Systems (E.G., Variable Speed, Direct Drive) Can Improve The Efficiency Of A Metal Lathe Upgrade?You can improve a metal lathe by using a variable speed drive system. This lets you change the speed easily for different tasks. A direct drive system can also help. It connects the motor straight to the lathe, making it stronger and smoother. Both types make the lathe work better and faster.

Are There Specific Power Requirements For Different Types Of Materials When Operating A Metal Lathe?Yes, different materials need different amounts of power when using a metal lathe. Soft materials, like aluminum, need less power. Harder materials, like steel, need more power to cut smoothly. If you choose the right power, you’ll get better results and avoid damaging the tools or materials. Always check what material you are using and adjust the power accordingly!

How Can Insufficient Power Supply Impact The Operation And Longevity Of An Upgraded Metal Lathe?If your metal lathe doesn’t get enough power, it won’t work well. You might see it slow down or stop. This can cause damage to the lathe, making it break sooner. Plus, it can lead to mistakes in your work. Overall, not having enough power can shorten the life of your lathe.