Have you ever wondered how precision tools like a lathe work? They can create amazing things from metal. But what if you want to get a good metal lathe without breaking the bank? Many people think that high precision comes at a high price. However, finding a cheap metal lathe with precise leveling is possible!

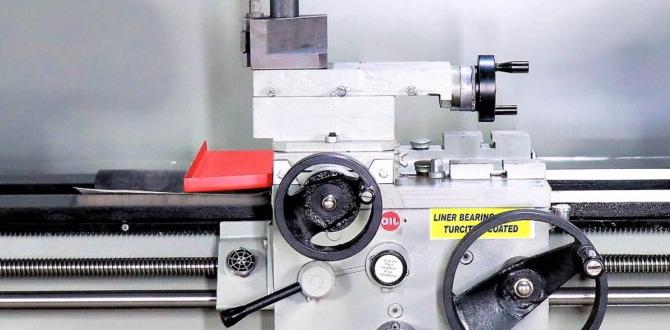

Imagine you’re in a workshop. You see a lathe spinning a piece of metal, shaping it smoothly. With the right setup, even a basic lathe can make incredible tools and parts. You don’t need to spend a fortune to make your projects come to life.

Here’s a fun fact: Did you know that leveling your lathe accurately can actually improve your work? It helps avoid problems like vibration and uneven cuts, which can ruin your projects. So, if you’re on the hunt for a budget-friendly metal lathe, remembering to focus on precision leveling can make all the difference!

Lathe Precision Leveling: Affordable Solutions For Cheap Metal Lathe

Understanding Lathe Precision Leveling for Cheap Metal Lathes

Are you looking to improve your metalworking skills? Lathe precision leveling for cheap metal lathes is crucial. Proper leveling helps ensure accurate cuts and smooth operations. You may wonder, how does this affect your project? Imagine creating perfect parts without wasting materials. A level lathe reduces wear and tear, saving you money in the long run. Plus, you can achieve impressive results without breaking the bank. So, why not try leveling your lathe today? It might change your metalworking game!Understanding Lathe Precision

Definition and importance of precision in metal lathes. The impact of leveling on lathe performance.Precision means making things just right. In metal lathes, being precise is crucial for creating parts that fit together perfectly. Imagine trying to fix a toy and using the wrong size screw—it just won’t work! Proper leveling of your lathe helps it perform its best. If it’s off, it can cause wobbles and weird shapes. So, keep it steady, and your projects will shout, “I’m perfect!”

| Benefit | Impact of Precision |

|---|---|

| Better Fit | Parts fit together smoothly. |

| Less Waste | Fewer errors mean less scrap. |

| More Savings | Save money on materials. |

Factors Influencing Lathe Precision Leveling

Surface flatness and its role in leveling. Weight distribution and center of gravity considerations.Lathe precision leveling is all about making your metal lathe work like a pro! Surface flatness is key; if the surface is bumpy, your lathe might play a tunes of its own. Proper weight distribution helps too. If it’s uneven, your lathe could tip like a teeter-totter! Remember, a good center of gravity keeps your machine steady and happy.

| Factor | Impact on Leveling |

|---|---|

| Surface Flatness | Ensures accurate cutting |

| Weight Distribution | Balances the machine |

| Center of Gravity | Prevents tipping |

Tools Required for Leveling Your Metal Lathe

Essential leveling tools and equipment. Recommended brands and types of tools for costeffective solutions.Leveling your metal lathe is crucial for smooth operation and accuracy. For this job, you’ll need a few key tools. First, grab a good quality spirit level. It’s like a trusty sidekick for keeping things straight! You might also want a precision straightedge to check your lathe’s bed. Brands like Starrett and Mitutoyo are reliable choices without breaking the bank. And don’t forget a torque wrench to ensure everything is snug yet not too tight. Happy leveling!

| Tool | Recommended Brand | Why It’s Great |

|---|---|---|

| Spirit Level | Stabila | Accurate and easy to read. |

| Precision Straightedge | Starrett | Durable and precise. |

| Torque Wrench | Craftsman | Affordable and reliable. |

Step-by-Step Guide to Leveling Your Lathe

Detailed procedures for leveling a cheap metal lathe. Common mistakes to avoid during the leveling process.Leveling your lathe helps it work better. Here’s how to do it right:

- First, find a flat surface. Use a bubble level to check it.

- Next, adjust the legs. You can raise or lower them until it’s steady.

- Finally, double-check with the level. Make sure it’s perfect!

Watch out for common mistakes. Don’t skip the bubble level. It’s crucial!

Also, ensure your lathe is clean. Dirt can throw it off balance.

How do I level my lathe properly?

Leveling your lathe properly ensures smooth operation and accurate cuts.

Common mistakes to avoid:

- Not using the bubble level.

- Neglecting to clean the area.

- Over-tightening the legs.

Testing and Calibration Techniques

Methods to test the precision after leveling. Calibration techniques for ensuring ongoing accuracy.To check if your metal lathe is working perfectly after leveling, you can use a few simple tricks. First, run a test piece of material through the lathe to see if it cuts smoothly. If it feels like a bumpy ride, there might be an issue. Next, measure your cut with a caliper or ruler. Remember, a good cut should fit like a glove!

| Method | Description |

|---|---|

| Test Cuts | Make cuts on a test piece to check for evenness. |

| Caliper Measurement | Use a caliper to measure the cut for accuracy. |

For ongoing accuracy, regular calibration is key. Adjust your lathe settings every so often, just like tuning a guitar. It makes the lathe sing! Set up a routine schedule to inspect your lathe. This will ensure your projects stay on track, and you won’t end up with a wobbly masterpiece. Remember: a small effort can save big time later!

Maintenance Tips for Sustained Precision

Regular maintenance practices to enhance lathe durability. Monitoring and adjustments to maintain precision over time.To keep a lathe running smoothly, regular care is important. This helps the machine last longer and stay precise. Here are some easy tips for maintenance:

- Check oil levels often.

- Clean the parts regularly.

- Tighten any loose screws.

- Inspect belts and gears for wear.

Making small adjustments can also help keep your lathe precise over time. Always measure your work to ensure it’s right. Caring for your lathe helps avoid big problems later!

How can I ensure my lathe stays precise?

Regular checks and small adjustments help keep the lathe precise. Measure often and look for wear to act quickly. Doing this can make your machine work better for a long time!

Common Issues and Troubleshooting

Identifying levelrelated issues with metal lathes. Troubleshooting steps to resolve common precision problems.Level-related issues can make your cheap metal lathe behave like a dance floor. One minute it’s spinning smoothly, and the next, it’s wobbling like a cat on a hot tin roof! To spot these problems, use a level tool to check if the lathe sits evenly. If it’s off, that’s your clue! Follow these troubleshooting steps:

| Issue | Fix |

|---|---|

| Wobbly Workpiece | Adjust the leveling feet until even. |

| Uneven Cuts | Check the tailstock alignment. |

| Noisy Operation | Inspect for loose parts and tighten them. |

Remember, keeping your lathe level is key for smooth operation. If you find trouble, don’t panic—fix it like a pro! After all, who doesn’t love a lathe that spins like a charm?

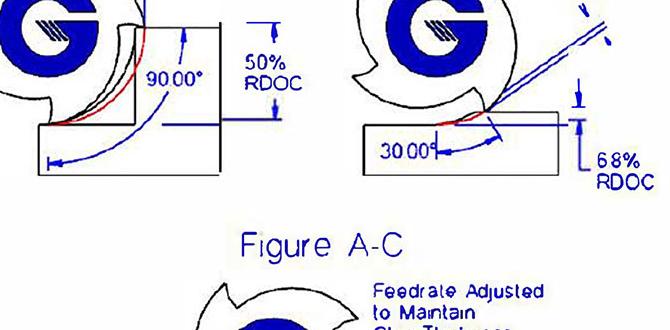

Affordable Upgrades for Enhanced Performance

Costeffective modifications to improve lathe precision. Assessing when it’s worth investing in better equipment.Upgrading your lathe doesn’t have to break the bank. Simple modifications can make a big difference. For example, adding a sturdy bed or a precision leveling system can improve the lathe precision without costing you an arm and a leg. When should you consider splurging on better equipment? If you’re consistently missing your targets, it might be time to invest. Remember, accurate tools save time and frustration—like having a GPS instead of a map in a snowstorm!

| Upgrade | Benefit | Cost |

|---|---|---|

| Precision Leveling System | Improves accuracy | Low |

| Sturdy Bed | Reduces vibrations | Moderate |

| Better Tool Holders | Increases stability | Moderate |

Invest smartly for smoother and speedier projects!

Expert Insights and Best Practices

Tips from experienced machinists on precision leveling. Recommended resources and community support for lathe enthusiasts.Taking tips from seasoned machinists can make all the difference in precision leveling. Here are some key suggestions:

- Always check the level after moving your lathe.

- Use a machinist’s level for accuracy.

- Adjust the feet until the bubble is centered.

- Consider using a digital level for easier readings.

For lathe enthusiasts, community support is crucial. Online forums and local clubs provide great resources. You can share your experiences and learn from others. Connecting with fellow hobbyists can help you solve problems too.

What are some resources for lathe enthusiasts?

Forums, YouTube tutorials, and local workshops are great for learning tips and tricks on lathe use.

Conclusion

In summary, using a lathe precision leveling tool helps ensure accuracy in your metalworking projects. Affordable metal lathes can deliver great results without breaking the bank. We encourage you to explore models within your budget and look for reviews to guide your choices. Happy machining—let’s create some amazing projects together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling For Cheap Metal Lathes:When you use a cheap metal lathe, it’s important to level it properly. This means making sure it sits flat and even. To do this, you can use a level tool. You should check the lathe from both sides and the front. If it’s not level, adjust the feet until it is. This helps your lathe work better and makes your projects look nicer.

Sure! Just give me the question you’d like me to answer, and I’ll help you with it!

What Techniques Can Be Used To Achieve Precision Leveling On A Budget-Friendly Metal Lathe?To achieve precision leveling on a budget-friendly metal lathe, you can use a few simple techniques. First, check the lathe’s feet and make sure they rest on a stable surface. You can use a bubble level to see if it’s flat. If not, you can adjust the feet or add shims to level it. Lastly, always tighten everything well to keep it steady while you work.

How Can I Identify If My Cheap Metal Lathe Is Properly Leveled For Optimal Performance?To check if your metal lathe is level, use a small bubble level. Place it on the lathe’s bed, which is the flat part where pieces sit. Adjust the legs until the bubble is in the middle. You can also try turning a piece of metal and see if it cuts evenly. If it feels smooth, your lathe is likely level!

What Tools And Materials Are Recommended For Leveling A Low-Cost Lathe Effectively?To level a low-cost lathe, you need a few simple tools. You should have a level tool to check the flatness. We also need wooden shims or metal shims to raise parts of the lathe if needed. A wrench helps to tighten screws or bolts. Don’t forget a measuring tape to check distances!

How Does The Leveling Of A Metal Lathe Affect The Quality Of The Machined Parts?When a metal lathe is not level, it can cause problems. If it’s tilted, the parts you make may be uneven or not fit well. Leveling helps the machine work accurately. This way, you get smoother and better-looking parts every time. It’s important for keeping everything working just right!

Are There Specific Challenges To Leveling Inexpensive Lathes Compared To Higher-End Models, And How Can They Be Addressed?Yes, leveling inexpensive lathes can be harder than leveling fancy ones. They might not be as sturdy, making them wobble. You can check if they are flat using a spirit level. If you notice a problem, put thin shims under the legs to fix it. Always take your time to make sure it’s just right!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling For Cheap Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a cheap metal lathe, it’s important to level it properly. This means making sure it sits flat and even. To do this, you can use a level tool. You should check the lathe from both sides and the front. If it’s not level, adjust the feet until it is. This helps your lathe work better and makes your projects look nicer.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just give me the question you’d like me to answer, and I’ll help you with it!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Achieve Precision Leveling On A Budget-Friendly Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To achieve precision leveling on a budget-friendly metal lathe, you can use a few simple techniques. First, check the lathe’s feet and make sure they rest on a stable surface. You can use a bubble level to see if it’s flat. If not, you can adjust the feet or add shims to level it. Lastly, always tighten everything well to keep it steady while you work.”}},{“@type”: “Question”,”name”: “How Can I Identify If My Cheap Metal Lathe Is Properly Leveled For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if your metal lathe is level, use a small bubble level. Place it on the lathe’s bed, which is the flat part where pieces sit. Adjust the legs until the bubble is in the middle. You can also try turning a piece of metal and see if it cuts evenly. If it feels smooth, your lathe is likely level!”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Recommended For Leveling A Low-Cost Lathe Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a low-cost lathe, you need a few simple tools. You should have a level tool to check the flatness. We also need wooden shims or metal shims to raise parts of the lathe if needed. A wrench helps to tighten screws or bolts. Don’t forget a measuring tape to check distances!”}},{“@type”: “Question”,”name”: “How Does The Leveling Of A Metal Lathe Affect The Quality Of The Machined Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When a metal lathe is not level, it can cause problems. If it’s tilted, the parts you make may be uneven or not fit well. Leveling helps the machine work accurately. This way, you get smoother and better-looking parts every time. It’s important for keeping everything working just right!”}},{“@type”: “Question”,”name”: “Are There Specific Challenges To Leveling Inexpensive Lathes Compared To Higher-End Models, And How Can They Be Addressed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, leveling inexpensive lathes can be harder than leveling fancy ones. They might not be as sturdy, making them wobble. You can check if they are flat using a spirit level. If you notice a problem, put thin shims under the legs to fix it. Always take your time to make sure it’s just right!”}}]}