Have you ever wondered how skilled machinists create precise parts with metal lathes? The answer lies in the art of lathe precision leveling. This method ensures that the lathe operates at the exact angle it needs for perfect cuts. Without this, even the best designs can go wrong.

Imagine building a toy robot. If the parts are not aligned, it won’t stand straight. The same happens with a metal lathe. It needs to be level to make sure everything fits just right. CAD design plays a huge role in this process. It helps create detailed plans that show every tiny detail of a project.

Did you know that even small mistakes in leveling can lead to big problems? A slight tilt can cause wear and tear on the tools. That’s why understanding lathe precision leveling is vital for anyone using a metal lathe. In this article, we’ll explore how to achieve that perfect level and how CAD design simplifies the task.

Lathe Precision Leveling For Metal Lathe Cad Design Guide

Understanding Lathe Precision Leveling in CAD Design

Lathe precision leveling plays a key role in metal lathe operations. Imagine making a fine table, and every part must be just right. Precision leveling ensures your lathe is perfectly aligned. This leads to smoother cuts and better results in your projects. CAD design helps visualize and plan the layout, making adjustments simpler. Did you know that a small error can cause big problems in machining? Understanding this can save time and improve your craftsmanship!Understanding Lathe Precision Leveling

Importance of precision leveling in lathe operation. Effects of uneven leveling on machining accuracy.Precision leveling is like the magic wand for a lathe machine. It helps machines work better and produce exact shapes. When a lathe is uneven, it can mess up the whole process. Imagine trying to draw a straight line on a crooked board – messy, right? Uneven leveling can cause errors in the parts made, making them less accurate. This means you may end up with items that are not just slightly off but totally wrong!

| Effects of Uneven Leveling | Impact on Machining |

|---|---|

| Poor surface finish | Rough parts |

| Inaccurate dimensions | Parts don’t fit together |

| Increased tool wear | More expensive repairs |

So, remember, keeping your lathe perfectly leveled is key. It’s as important as wearing matching socks on a big day!

Tools and Techniques for Leveling a Metal Lathe

Essential tools for lathe leveling. Stepbystep techniques to achieve precise leveling.To level your lathe like a pro, you’ll need some handy tools. Start with a level, of course. A machinist’s level is perfect for this job. You can also grab shims for tiny adjustments, like trying to find that one perfect pancake in a stack.

| Essential Tools | Purpose |

|---|---|

| Machinist Level | Checks and ensures flatness. |

| Shims | Helps lift and balance the lathe. |

Begin by placing your machinist level on the lathe bed. Look for bubbles—no, not the fun kind—but the bubble in the level. Adjust with shims until it’s centered. Repeat this across different points for optimal precision. Remember, a level lathe is a happy lathe! And a happy lathe makes great metal masterpieces.

Common Challenges in Lathe Leveling

Issues faced during the leveling process. Solutions and troubleshooting tips for common problems.Leveling a lathe can be tricky. Common problems include uneven surfaces, incorrect measurements, and loose components. These issues can lead to poor accuracy. To fix them, first check your lathe’s feet and ensure they’re stable. Use a spirit level for precision—after all, even a lathe deserves a little balance! Tighten loose parts and recalibrate if needed. Remember, if your lathe feels wobbly, it might just be trying to dance!

| Challenges | Solutions |

|---|---|

| Uneven surface | Use a leveling tool |

| Incorrect measurements | Double-check with a ruler |

| Loose components | Tighten all screws |

Best Practices for Maintaining Lathe Precision

Regular checks and maintenance routines. Importance of environmental factors in precision engineering.Keeping a lathe in top shape needs careful attention. Regular checks help catch problems early. Make sure to inspect your lathe often to keep it precise. Also, remember that the shop’s environment matters. Dust, temperature, and humidity can all affect your work. Follow these tips for best results:

- Check alignment and level frequently

- Clean the lathe regularly

- Store tools in a dry area

- Monitor temperature and humidity

By following these practices, you can enhance the longevity and efficiency of your lathe.

Why is it important to regularly check lathe precision?

Regular checks ensure your lathe stays accurate and reliable. This helps in preventing costly mistakes. Checking precision often will help you achieve better results in your projects.

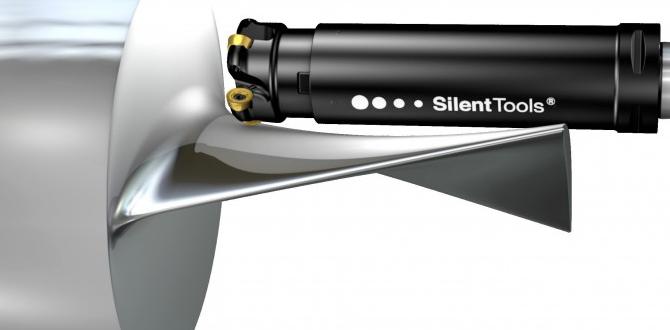

Incorporating CAD Design into Lathe Operations

The role of CAD software in enhancing lathe designs. Benefits of integrating CAD with precision leveling procedures.Using CAD software can make lathe operations smoother and more precise. It allows designers to create detailed plans before cutting metal. This means fewer mistakes and less wasted material. Imagine drawing the perfect cupcake before baking—less mess and more sweet success! Integrating CAD with precision leveling helps ensure that your lathe is perfectly set up for every cut. This combination can lead to faster production and higher quality products. Here’s what CAD brings to the table:

| Benefit | Description |

|---|---|

| Precision | Less room for error in designs. |

| Speed | Faster designs mean quicker outputs. |

| Flexibility | Easy changes to designs if needed. |

So, embrace CAD in your lathe work. Your creations will be more precise, and you might even have time for a cupcake break!

Case Studies: Successful Lathe Precision Leveling

Examples of businesses that improved productivity through lathe leveling. Lessons learned from precision leveling implementations.Many companies have seen big boosts in productivity by using lathe precision leveling. One factory reported a production increase of 25% after implementing this technique. Another small shop reduced waste by 30% through careful leveling. They learned that small adjustments can lead to big results. Each case shows that taking the time to level machines can make a real difference.

- Better product quality

- Less machine wear

- Safer work environment

What are the benefits of lathe precision leveling?

Lathe precision leveling improves product quality, reduces waste, and enhances safety. This means machines work better and last longer. It’s a smart move for any business aiming for success.

Future Trends in Lathe Precision and CAD Technology

Innovations in lathe leveling technology. The evolution of CAD tools for advanced machining precision.New technology is changing how we use lathes. Lathe leveling technology is now more advanced. Machines can self-adjust, making them more accurate. These machines save time and reduce errors. Similarly, CAD tools have evolved for better designs. They help create precise models for machining. This means products are made more efficiently and with fewer mistakes.

What are some innovations in lathe leveling technology?

Some innovations include self-leveling machines and sensor technology. These developments help improve accuracy and reduce manual adjustments.

What advancements exist in CAD tools?

- Intuitive interfaces for easy design.

- Real-time simulations to test designs.

- Enhanced cloud collaboration for teamwork.

Conclusion

In summary, lathe precision leveling is crucial for quality metal work. Good CAD design helps you visualize your projects better. Accurate leveling ensures your cuts are clean and precise. We encourage you to explore CAD software for practice. By understanding these concepts, you can improve your skills and produce better results. Keep learning and experimenting!FAQs

What Are The Best Practices For Achieving Precision Leveling On A Metal Lathe During Setup?To achieve precision leveling on a metal lathe, we start by placing it on a sturdy, flat surface. You should use a level tool to check that the lathe is straight. If it’s not, you can adjust the feet or base until it is level. Make sure all parts are tight and secure. Finally, double-check the level after adjusting, to ensure everything is just right.

How Can Cad Design Tools Be Utilized To Enhance The Accuracy Of A Metal Lathe’S Components?We can use CAD, which stands for Computer-Aided Design, to make better metal lathe parts. With CAD, we can draw and design parts on a computer. This helps us see how everything will fit together before making it. We can check sizes and shapes closely, which makes parts more accurate. Using CAD saves time and reduces mistakes when we build our metal lathe components.

What Materials And Components Are Essential For Constructing A Precision-Leveling System For A Lathe?To build a precision-leveling system for a lathe, you need a few important materials. First, get adjustable leveling feet. These help keep the lathe steady on uneven floors. Next, use a strong, flat surface or base to support the lathe. Finally, include a reliable level tool to check if the lathe is perfectly straight. These parts will help you work accurately!

How Does The Leveling Of A Metal Lathe Impact Its Performance And The Quality Of The Finished Workpieces?Leveling a metal lathe is really important. If it’s not level, the machine can wobble. This makes it harder to cut metal correctly. When the lathe is level, it helps us make smooth and perfect workpieces. So, always check if your lathe is level before starting!

What Are The Common Methods For Measuring And Adjusting The Level Of A Metal Lathe In A Workshop Environment?To measure and adjust the level of a metal lathe, we can use a few simple methods. First, we can place a bubble level on the lathe bed. The bubble shows if the lathe is straight or tilted. If it’s not level, we can use shims or adjust the lathe’s feet to fix it. Lastly, measuring from the floor to different parts of the lathe can help us make sure it’s even.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Best Practices For Achieving Precision Leveling On A Metal Lathe During Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To achieve precision leveling on a metal lathe, we start by placing it on a sturdy, flat surface. You should use a level tool to check that the lathe is straight. If it’s not, you can adjust the feet or base until it is level. Make sure all parts are tight and secure. Finally, double-check the level after adjusting, to ensure everything is just right.”}},{“@type”: “Question”,”name”: “How Can Cad Design Tools Be Utilized To Enhance The Accuracy Of A Metal Lathe’S Components? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can use CAD, which stands for Computer-Aided Design, to make better metal lathe parts. With CAD, we can draw and design parts on a computer. This helps us see how everything will fit together before making it. We can check sizes and shapes closely, which makes parts more accurate. Using CAD saves time and reduces mistakes when we build our metal lathe components.”}},{“@type”: “Question”,”name”: “What Materials And Components Are Essential For Constructing A Precision-Leveling System For A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To build a precision-leveling system for a lathe, you need a few important materials. First, get adjustable leveling feet. These help keep the lathe steady on uneven floors. Next, use a strong, flat surface or base to support the lathe. Finally, include a reliable level tool to check if the lathe is perfectly straight. These parts will help you work accurately!”}},{“@type”: “Question”,”name”: “How Does The Leveling Of A Metal Lathe Impact Its Performance And The Quality Of The Finished Workpieces? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Leveling a metal lathe is really important. If it’s not level, the machine can wobble. This makes it harder to cut metal correctly. When the lathe is level, it helps us make smooth and perfect workpieces. So, always check if your lathe is level before starting!”}},{“@type”: “Question”,”name”: “What Are The Common Methods For Measuring And Adjusting The Level Of A Metal Lathe In A Workshop Environment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure and adjust the level of a metal lathe, we can use a few simple methods. First, we can place a bubble level on the lathe bed. The bubble shows if the lathe is straight or tilted. If it’s not level, we can use shims or adjust the lathe’s feet to fix it. Lastly, measuring from the floor to different parts of the lathe can help us make sure it’s even.”}}]}