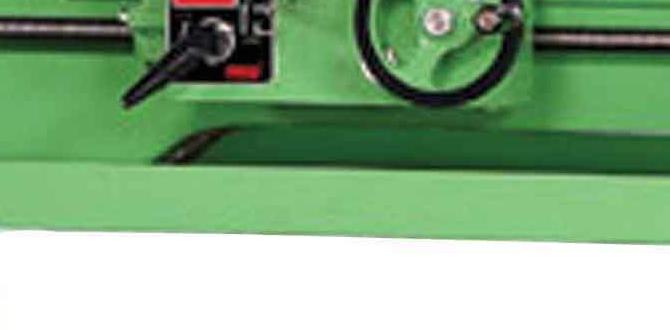

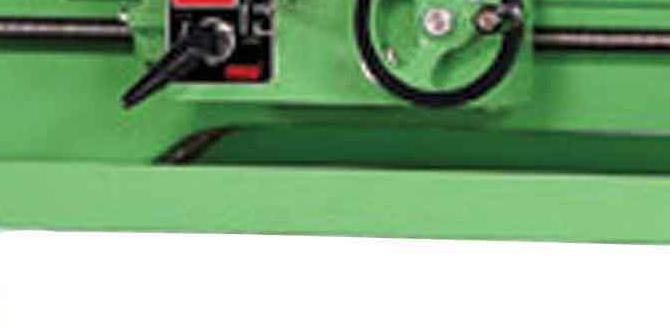

Have you ever watched a metal lathe in action? It spins metal like a magician, turning raw pieces into smooth, precise shapes. But did you know that just like any skilled craft, a lathe needs to be set up correctly for the best results?

Imagine trying to build a tower with uneven blocks. It would collapse, right? That’s why lathe precision leveling is crucial. If your lathe isn’t stable, your work can end up uneven or flawed.

The control panel of a metal lathe plays a significant role in this process. It’s where you tell the machine what to do. Having the right settings ensures each cut is just right.

In this article, we will explore how to achieve perfect lathe precision leveling. You’ll learn why it matters and how the control panel helps your lathe perform at its best. Ready to unleash the true potential of your metal lathe? Let’s get started!

Lathe Precision Leveling: Metal Lathe Control Panel Guide

Lathe Precision Leveling and Control Panel Insights

Lathe precision leveling is essential for accurate metalworking. An unlevel lathe can lead to errors and poor finishing. It’s like trying to draw with a tilted paper! A well-set control panel simplifies adjustments, ensuring smooth operation. Did you know that the right leveling can extend your machine’s life? Simple steps can make a big difference. Understanding these key points helps improve your lathe’s performance and your projects’ quality.Understanding Lathe Precision Leveling

Definition of lathe precision leveling. Importance of leveling for machining accuracy.Lathe precision leveling means making sure the lathe is flat and straight. This is very important. If a lathe isn’t leveled, it can cause mistakes in cutting. This can make parts not fit well or be weak. Accurate leveling helps in getting better results.

- Improves machining accuracy

- Reduces wear on tools

- Increases safety while working

Why is leveling important for a lathe?

Leveling ensures that the lathe works correctly. It leads to better quality in all projects.

Common Challenges in Lathe Leveling

Factors affecting precision leveling. Consequences of improper leveling on performance.Leveling a lathe isn’t just about finding a flat spot. Factors like floor stability and temperature changes can mess with precision leveling. If your lathe isn’t level, it can cause serious headaches. You might end up with uneven cuts, which is like trying to bake a cake without measuring flour. Not fun! A wobbling lathe can also lead to faster wear and tear, costing you time and money. Here’s a table on how leveling affects performance:

| Issue | Consequence |

|---|---|

| Unstable floor | Poor precision in cuts |

| Temperature changes | Warped materials |

| Improper leveling | Increased tool wear |

So, remember to check your lathe before you start working, or you may end up with a real-life game of “how crooked can this be?”

Tools and Equipment for Precision Leveling

Essential leveling tools and their functions. Recommended brands and products for metal lathes.Leveling a metal lathe needs some handy tools. First up, a good spirit level helps check if your lathe sits flat like a pancake. Next, precision leveling feet raise or lower corners to match the spirit level. Brand-wise, Starrett and Mitutoyo are top choices. Don’t forget a reliable digital angle finder! It’s the superhero that makes sure everything is just right. Check out this table for product recommendations:

| Tool | Brand | Purpose |

|---|---|---|

| Spirit Level | Starrett | Check flatness |

| Leveling Feet | Mitutoyo | Adjust height |

| Digital Angle Finder | iGaging | Measure angles |

Step-by-Step Guide to Leveling a Metal Lathe

Detailed leveling procedure with illustrations. Tips for achieving optimal leveling results.Leveling your metal lathe ensures it runs smoothly. Start with these steps: First, check the floor for flatness with a spirit level. Then, adjust the lathe feet using leveling screws. Use a dial indicator on the carriage to check heights. Repeat until you achieve even results. For better leveling:

- Check regularly to maintain precision.

- Use a gauge to track adjustments.

- Practice patience for perfect alignment.

Each step helps maintain quality and extends your machine’s life.

Why is leveling important?

Correctly leveling your lathe leads to better carving and cutting. It helps prevent errors and makes your work more precise. A well-leveled lathe can improve your final results!

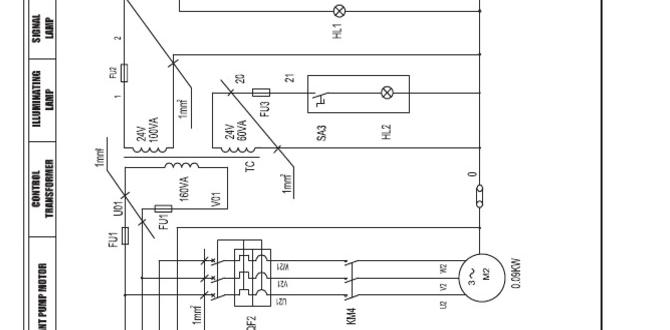

How to Adjust the Control Panel for Precision Lathe Operations

Key features of a lathe control panel. Best practices for calibrating settings for precision work.Understanding your lathe control panel is essential for smooth operation. Key features include speed control, feed rate adjustment, and tool position settings. These help in achieving fine precision in your work. For best results, always calibrate settings before starting. Check and adjust settings regularly. This ensures accuracy and repeatability in your projects. Remember to keep your workspace clean to avoid errors and distractions.

What are the key features of a lathe control panel?

The key features often include:

- Speed control for smooth operation

- Feed rate adjustment for cutting depth

- Tool position settings for precise placement

How to calibrate the control panel for precision work?

Calibrating involves:

- Going through the user manual

- Adjusting speed and feed rates before starting

- Making sure all settings match your project’s needs

Regular Maintenance Practices for Enhanced Precision

Routine checks and adjustments for optimal performance. Common maintenance mistakes to avoid.Taking care of your lathe ensures it runs smoothly. Regular checks are key to keeping everything balanced. Adjustments like leveling the lathe can make a big difference. Forgetting to inspect the bolts? That’s like leaving your shoelaces untied — a disaster waiting to happen! Avoid common mistakes like skipping lubrication; machines can get grumpy when dry. Remember, a happy lathe is a precise lathe!

| Common Maintenance Mistakes | Tips to Avoid Them |

|---|---|

| Skipping Routine Checks | Set a reminder on your phone! |

| Forgetting Lubrication | Oil is your lathe’s best friend! |

| Ignoring Calibration | Check those settings often! |

Real-Life Applications of Precision Leveling in Metal Lathes

Case studies demonstrating leveling impact on production. Industries benefiting from precision lathe operations.Precision leveling plays a crucial role in improving metal lathe operations. In factories, workers have noticed that well-leveled lathes produce parts that fit better. For instance, one company reduced its errors by 30% after leveling its machines. This made their products more reliable. Industries like automotive and aerospace thrive on precise measurements. It saves time and money, allowing them to focus on making cool stuff, like fancy cars and sleek airplanes!

| Industry | Benefits of Precision Leveling |

|---|---|

| Automotive | Better accuracy and fewer defects |

| Aerospace | Increased safety and performance |

| Manufacturing | Higher productivity and quality |

Expert Tips for Experienced Operators

Advanced techniques for maintaining precision. Troubleshooting common issues in lathe operations.To keep your lathe working well, you need some expert tips. Here are effective ways to maintain precision:

- Check alignment: Regularly make sure your lathe is level. A tiny tilt can cause big problems.

- Clean regularly: Dust and grease affect movement. Keep your machine clean for better results.

- Test parts: Run small test pieces to spot issues early. This can save time and materials.

If you face problems, troubleshoot quickly:

- Noisy operation: Check for loose bolts or worn bearings.

- Inconsistent cuts: Make sure your tools are sharp and correctly set.

- Chatter: Adjust speed and feed rates to smooth things out.

What should I do if my lathe isn’t operating correctly?

If your lathe isn’t working as expected, check for loose parts or misalignment first. Clean it often and ensure your tools are sharp. This will help improve performance and prolong the machine’s life.

Future Trends in Lathe Precision and Control Technology

Innovations shaping the future of metal lathes. The role of automation and smart technology in lathe precision.The world of metal lathes is buzzing with exciting changes! Innovations are popping up everywhere, making machines smarter. Automation is like having a robot buddy that helps you work better. It’s all about precision, folks! For example, automatic controls can adjust settings with just a click. This means your metal lathe can shape metal with amazing accuracy, kind of like a magician! As we dive into the future, expect even cooler tech to make your projects easier and more fun.

| Trend | Description |

|---|---|

| Smart Technology | Devices that learn and adapt to your work style. |

| Automation | Robots helping with repetitive tasks to save time. |

| AI Control Panels | User-friendly interfaces that are easy as pie! |

Conclusion

In conclusion, precise leveling of your metal lathe is crucial for quality work. A well-calibrated control panel helps you achieve accuracy. Remember to check your leveling regularly to improve results. We encourage you to try these tips and explore more about lathe maintenance. With practice, you’ll enhance your skills and enjoy better projects. Happy spinning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And The Control Panel Of A Metal Lathe:When we talk about lathe precision leveling, we mean making sure the lathe is perfectly flat and straight. This helps it work better. The control panel of a metal lathe has buttons and displays you use to make the lathe move. It lets you choose how fast to spin the metal and how deep to cut. Keeping everything level and using the control panel correctly helps us create nice, smooth shapes.

Sure! Please provide the question you’d like me to answer.

What Are The Key Steps Involved In Leveling A Metal Lathe To Ensure Precision During Machining?To level a metal lathe, first find a flat surface where it will sit. Next, use a bubble level to check if it’s straight. If it’s not, adjust the legs of the lathe until it is level. Finally, double-check with the level to be sure it’s just right. This helps make your work more accurate!

How Does The Control Panel Of A Metal Lathe Influence The Accuracy Of Machining Operations?The control panel of a metal lathe helps you choose the right settings for cutting metal. When you set the speed and feed correctly, you get better shapes and sizes. If you make a mistake with these settings, your piece might not turn out right. So, the control panel is important for making accurate parts!

What Tools And Equipment Are Recommended For Leveling A Metal Lathe Effectively?To level a metal lathe, you need a few important tools. First, use a spirit level to check if it’s straight. You will also need adjustable feet or shims to raise or lower parts of the lathe. A tape measure helps you see if everything is the right size. Lastly, a wrench will help you tighten bolts as you make adjustments.

How Can Operator Adjustments On A Lathe’S Control Panel Affect The Overall Performance And Precision Of The Machine?When you adjust the control panel on a lathe, you change how the machine works. For example, you can make it spin faster or slower. These changes help make the parts you’re shaping more accurate. If you make the right adjustments, your work will look and fit better. So, what you do on the control panel really matters for good results!

What Common Issues Can Arise From Improper Leveling Of A Metal Lathe, And How Can They Impact The Machining Process?If a metal lathe isn’t leveled right, it can cause problems. You might see uneven parts, making them fit badly. It can also lead to extra noise and vibrations. These issues slow down your work and can waste materials. So, it’s important to level it well for better results!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And The Control Panel Of A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we talk about lathe precision leveling, we mean making sure the lathe is perfectly flat and straight. This helps it work better. The control panel of a metal lathe has buttons and displays you use to make the lathe move. It lets you choose how fast to spin the metal and how deep to cut. Keeping everything level and using the control panel correctly helps us create nice, smooth shapes.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Leveling A Metal Lathe To Ensure Precision During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, first find a flat surface where it will sit. Next, use a bubble level to check if it’s straight. If it’s not, adjust the legs of the lathe until it is level. Finally, double-check with the level to be sure it’s just right. This helps make your work more accurate!”}},{“@type”: “Question”,”name”: “How Does The Control Panel Of A Metal Lathe Influence The Accuracy Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The control panel of a metal lathe helps you choose the right settings for cutting metal. When you set the speed and feed correctly, you get better shapes and sizes. If you make a mistake with these settings, your piece might not turn out right. So, the control panel is important for making accurate parts!”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Recommended For Leveling A Metal Lathe Effectively?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, you need a few important tools. First, use a spirit level to check if it’s straight. You will also need adjustable feet or shims to raise or lower parts of the lathe. A tape measure helps you see if everything is the right size. Lastly, a wrench will help you tighten bolts as you make adjustments.”}},{“@type”: “Question”,”name”: “How Can Operator Adjustments On A Lathe’S Control Panel Affect The Overall Performance And Precision Of The Machine?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you adjust the control panel on a lathe, you change how the machine works. For example, you can make it spin faster or slower. These changes help make the parts you’re shaping more accurate. If you make the right adjustments, your work will look and fit better. So, what you do on the control panel really matters for good results!”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise From Improper Leveling Of A Metal Lathe, And How Can They Impact The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe isn’t leveled right, it can cause problems. You might see uneven parts, making them fit badly. It can also lead to extra noise and vibrations. These issues slow down your work and can waste materials. So, it’s important to level it well for better results!”}}]}