Have you ever wondered how craftsmen make perfectly shaped metal parts? Achieving precision in metalworking is no easy task. It often requires advanced tools and techniques. One important tool is the lathe. A lathe allows you to shape metal with great accuracy.

A key part of using a lathe is ensuring it is level. If a lathe is not properly leveled, it can affect the quality of your work. A simple tilt can lead to uneven cuts. That’s why lathe precision leveling is so vital.

But how do you ensure your lathe is level? Enter the metal lathe controller board. This smart device helps manage the lathe’s operations. It can help you monitor and adjust settings easily. With its help, even beginners can achieve professional-level results!

Isn’t it amazing that technology can enhance traditional skills? Imagine creating a perfect gear or a beautiful vase, all thanks to precision tools. In this article, we will dive into the world of lathe precision leveling and explore how controller boards can make your metalworking projects easier and more fun.

Lathe Precision Leveling: Metal Lathe Controller Board Guide

Lathe Precision Leveling Metal Lathe Controller Board

Precision leveling is crucial for successful metal lathe operations. A well-leveled lathe ensures accurate cuts, reducing errors and waste. The lathe controller board plays a key role in maintaining this precision. It helps control speed and movements smoothly. Did you know that an unlevel lathe can lead to catastrophic failures? Ensuring your lathe is level creates better results. Discovering the right controller board can transform your metalworking experience, making it faster and more enjoyable.Understanding Metal Lathe Precision Leveling

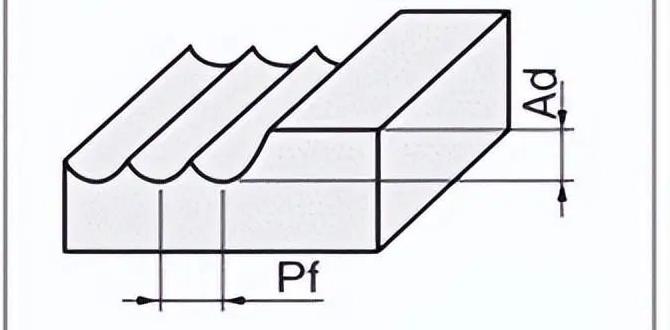

Importance of precision leveling in metalworking. Factors affecting lathe performance and accuracy.Precision leveling is crucial for metalworking. It ensures that the lathe operates smoothly and creates accurate parts. If the lathe is not level, it can affect the cut quality. This can lead to mistakes and wasted materials. Many factors influence a lathe’s performance:

- Surface level of the setup area

- Weight distribution on the lathe

- Temperature changes affecting materials

By mastering precision leveling, metalworkers can improve both accuracy and efficiency in their projects.

Why is precision leveling important for lathe performance?

Precision leveling helps ensure that cuts are even and consistent. It supports better quality work and helps avoid costly mistakes.

Steps for Precision Leveling Your Metal Lathe

Tools required for effective leveling. Stepbystep guide to achieve optimal leveling.To level your metal lathe precisely, you need a few tools. Gather a leveling gauge, a caliper, and a wrench set. Follow these steps for best results:

- Check the surface for any bumps or dips.

- Place the leveling gauge on the lathe bed.

- Adjust the feet using the wrench until the gauge shows level.

- Recheck with the caliper for accuracy.

- Repeat if necessary until perfectly level.

Proper leveling makes your lathe work better. It can save time and money!

What tools do I need to level my metal lathe?

You will need a leveling gauge, caliper, and a wrench set for effective leveling.

Common Issues with Metal Lathe Leveling

Identifying misalignment signs. Troubleshooting frequent leveling problems.Sometimes, your metal lathe might not work right. You may notice some signs of misalignment. Look for uneven cuts or vibrations. These can mean that the lathe is not level. Troubleshooting these problems is essential. Check the following:

- Check if the bed is flat.

- Examine the level of the tailstock.

- Ensure the headstock is aligned.

Fixing these issues helps your lathe run smoothly. This way, you get precise results!

What are common signs of misalignment?

Common signs include uneven surfaces and strange sounds. These hints tell you that the lathe needs help. Fixing these quickly can save you time and materials.

Advanced Techniques for Precision Leveling

Techniques for highprecision applications. Utilizing digital levels and lasers for accuracy.Achieving precision in leveling can make a big difference in your projects. High-precision applications need careful setup. Using digital levels or lasers can help you get it right. These tools measure small differences very accurately. Here are some techniques to consider:

- Use a digital level to check flatness.

- Employ laser levels for straight lines and angles.

- Check your setup frequently for any errors.

With these methods, you can improve your lathe precision leveling metal lathe controller board projects greatly. It makes everything easier and more accurate!

What are the benefits of using digital levels and lasers?

Digital levels and lasers provide high accuracy and quick measurements. They can help you see even tiny changes in angle or flatness, making your work more reliable.

Maintenance Tips for Metal Lathes and Controllers

Regular checks and calibrations to ensure precision. Best practices for maintaining controller board performance.Keeping your metal lathe and controller in good shape is important for smooth work. Regular checks help keep everything precise. Here are simple tips:

- Check for wear and tear weekly.

- Calibrate your machine every month.

- Clean the controller board often.

- Use a soft cloth to wipe dust away.

- Inspect connections and wires regularly.

These steps help ensure your machine runs smoothly, making your work easier.

How often should I check my metal lathe and controller?

Check your lathe and controller at least once a month. This helps catch issues early. Regular checks save time and effort later.

Best practices for controller care:

- Keep software up to date.

- Protect from moisture and extreme temperatures.

Resources and Tools for Metal Lathe Enthusiasts

Recommended tools for effective lathe leveling. Online resources and communities for learning and support.For metal lathe enthusiasts, the right tools can make a world of difference. An accurate lathe leveler is essential for smooth operation. You might also want micrometers, dial indicators, and a sturdy spirit level. Don’t forget to explore online forums and websites devoted to metalworking! They can provide tips and support. You can even join communities where members share their projects and because who wouldn’t want to celebrate a freshly crafted piece?

| Tool | Purpose |

|---|---|

| Lathe Leveler | Ensures your lathe is perfectly horizontal. |

| Micrometers | Measure small dimensions with precision. |

| Dial Indicator | Checks alignment and runout. |

| Spirit Level | Confirms your setup is level. |

Using the right resources can take your projects to the next level. So gear up, and let’s get turning! 🚀

Conclusion

In conclusion, a lathe precision leveling metal lathe controller board helps improve your machining accuracy. It ensures smooth operation and precise cuts. Understanding how to use it can enhance your projects significantly. We encourage you to explore resources and tutorials to learn more. With practice, you can master your lathe and create amazing workpieces!FAQs

Sure! Here Are Five Questions Related To Lathe Precision Leveling And Metal Lathe Controller Boards:Sure! Here are five questions about lathe precision leveling and metal lathe controller boards: 1. What does precision leveling mean? Precision leveling means making sure the lathe, a machine tool, is flat and straight. This helps it work correctly. 2. Why is precision important in a lathe? Precision is important because it makes sure the metal parts we create are just right. It helps avoid mistakes. 3. What is a metal lathe? A metal lathe is a machine that shapes metal into different forms. We can cut, smooth, and drill it. 4. What is a controller board? A controller board is a part of the machine that helps you control how the lathe works. It tells the lathe what to do. 5. How can I check if my lathe is level? You can use a level tool to check if your lathe is straight. Just place it on the machine and see if the bubble is centered.

Sure! Please give me the question you’d like me to answer.

What Are The Key Features To Look For In A Controller Board For Optimizing Precision Leveling On A Metal Lathe?When choosing a controller board for a metal lathe, focus on a few key features. First, make sure it has smooth movement control. This helps you level the lathe accurately. Look for easy settings to adjust the height. You also want it to connect well with other tools. Good feedback from the board helps you know if everything is working right.

How Does The Accuracy Of The Leveling System Affect The Overall Performance And Quality Of The Metal Lathe’S Machining?The leveling system helps keep the metal lathe steady. If it’s not accurate, the lathe might wobble. This wobbling can cause mistakes in the metal parts we make. When the lathe works well, we get better-looking and stronger metal pieces. So, a good leveling system means better parts!

What Methods Or Technologies Are Available For Electronically Measuring And Adjusting The Level Of A Metal Lathe?You can use special devices like digital levels and sensors to measure a metal lathe’s position. These tools show you if the lathe is straight or tilted. You can adjust the feet of the lathe to make it level. Some machines also have built-in screens to help you see the measurements. This way, you can make sure everything is just right for your project!

Can Integrating A Modern Cnc Controller Board Improve The Precision And Repeatability Of Operations On A Metal Lathe?Yes, using a modern CNC controller board can help you make better parts on a metal lathe. It tells the machine exactly what to do. This way, each piece you make is very close to the same size and shape. You will see fewer mistakes and better results when you use it. Overall, it makes your work easier and more accurate!

What Common Challenges Arise When Attempting To Achieve Precision Leveling On A Metal Lathe, And How Can They Be Addressed?When using a metal lathe, you might face problems like uneven surfaces or machine vibrations. These can happen if the lathe isn’t level or if it’s placed on a wobbly table. To fix this, you should check the level with a tool called a level gauge. Adjust the feet of the lathe or place it on a sturdy table. This helps make sure you get smooth and accurate cuts.