Have you ever wondered how to get the best results from a metal lathe? Precision leveling can make a huge difference in your work. Imagine trying to create a perfect part, but your machine is off by just a little bit. It can ruin your project! That’s why understanding lathe precision leveling is so important.

Coolant plays a big role too. It helps keep the metal from getting too hot while you work. This can help your machine run smoothly and your parts come out just right. Who wouldn’t want better quality and longer-lasting tools?

In this article, we’ll explore how to level your lathe and the importance of using coolant. You may even learn some tips and tricks that seasoned metalworkers swear by. Ready to dive in? Let’s get started!

Lathe Precision Leveling: Essential Metal Lathe Coolant Techniques

Lathe Precision Leveling and Metal Lathe Coolant

Precision leveling of a metal lathe is essential for achieving accurate cuts. A level lathe improves the quality of work, reducing errors and rework. Coolant plays a big role too; it keeps the tool cool and helps with cutting fluid. Did you know that using the right coolant can extend the life of your tools? Proper leveling and coolant choices help craftsmen produce smooth, high-quality pieces every time.Understanding Lathe Precision

Definition and importance of precision in lathe work. Factors affecting lathe precision in machining operations.Precision in lathe work means making parts exactly as needed. This accuracy is key for quality and safety. Small mistakes can lead to big problems. Lathe precision is vital for industries like aerospace and automotive. Many things can affect this precision, including:

- Quality of the lathe tools

- Machine setup

- Operator skill level

- Type of materials used

- Coolant and maintenance practices

By focusing on these factors, we can ensure better results in machining operations.

Why is precision important in lathe work?

Precision ensures that parts fit together correctly. It saves time and materials in making parts. High accuracy leads to fewer mistakes and better products.

Step-by-Step Lathe Leveling Process

Preparation before leveling a metal lathe. Detailed procedures for ensuring optimal lathe leveling.Before leveling your metal lathe, make sure you have everything ready. First, clear the area around the lathe. This helps prevent accidents—no one wants to trip on a stray wrench! Check for any tools left behind; they like to play hide and seek. Next, use a level to find out how off your lathe really is. Adjust it until it’s just right.

| Preparation Steps | Notes |

|---|---|

| Clear the workspace | Accidents be gone! |

| Check tools | No tools left behind! |

| Use a level | Find those pesky tilts! |

With your area prepped and your tool check complete, it’s time to start leveling the lathe. Make small adjustments; think of it like fine-tuning a guitar. After each tweak, recheck the level. Getting everything just right means your lathe will run smoothly, and you can avoid that questionable dodgy wobble!

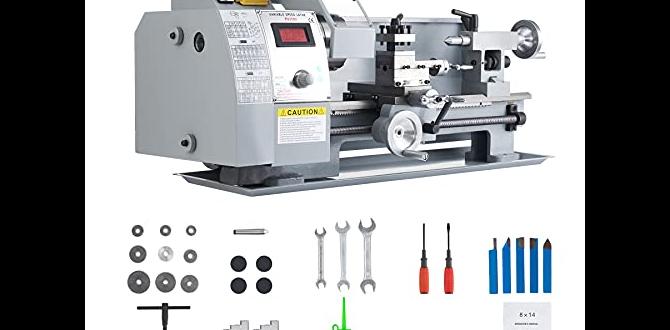

The Role of Metal Lathes in Precision Machining

Types of metal lathes available for various applications. Features of metal lathes that enhance precision.Metal lathes are essential tools in precision machining. They come in various types, like manual lathes for hands-on work and CNC lathes for automated precision. Each type has unique features that enhance accuracy, such as adjustable speed controls and high-quality coolant systems to keep everything running smoothly. Did you know that the right coolant can make your machining process as smooth as butter on a hot griddle? Without it, you might just invite overheating, which isn’t very welcoming!

| Type of Lathe | Benefits |

|---|---|

| Manual Lathe | Great for learning and tough projects |

| CNC Lathe | High precision and efficiency |

Using the right lathe and features can greatly improve the outcome of your projects, making them not only precise but also fun!

Choosing the Right Coolant for Metal Lathes

Types of coolant options available. Benefits of using coolant in precision machining.Choosing the right coolant is important for metal lathes. There are a few types of coolants you can use:

- Water-based coolants

- Oil-based coolants

- Synthetic coolants

Using the right coolant has many benefits:

- It helps keep tools cool during machining.

- It reduces wear on tools, making them last longer.

- It improves the surface finish of the metal being worked on.

In fact, using coolant can increase tool life by up to 300%!

What does coolant do for metal lathes?

Coolant keeps machines running smoothly by coolings tools and reducing friction. This helps make precision parts and keeps everything working well.

Coolant Management Techniques

Best practices for applying coolant during operation. Tips for maintaining coolant quality and performance.Using coolant well is important for smooth operations. Good practices help machines run better and last longer. Here are some tips:

- Apply coolant evenly for better results.

- Keep the coolant at the right temperature.

- Change the coolant regularly to maintain quality.

- Check for contamination often.

These steps can help you avoid problems and ensure your machine works its best.

Why is coolant quality important?

Coolant quality ensures smooth operation and prevents damage. This keeps your metal lathe in top shape and reduces downtime. Regular maintenance saves costs too!

Common Lathe Precision Issues and Solutions

Identifying and troubleshooting precisionrelated problems. Preventive measures to avoid precision errors in lathe work.Lathe precision issues can lead to poor results. You may find uneven cuts or strange noises while working. These signs show that something is wrong. Troubleshoot the problem by checking the alignment and wear on the tools. Preventive measures are vital for smooth operation. Regularly clean the lathe and ensure proper coolant is used. Consistent checks can avoid errors and keep your projects on track.

What are common precision issues with lathes?

Common issues include:

- Uneven surface finishes

- Incorrect dimensions

- Vibration during operation

How can I prevent precision errors in lathe work?

Some solutions are:

- Regular maintenance

- Protecting against dust and debris

- Using quality tools and materials

Advanced Techniques for Enhanced Lathe Precision

Upgrades and modifications to improve precision. Innovations in technology impacting lathe performance and precision.To improve lathe precision, consider upgrades and smart choices. New technologies help machines work better than before. Here are some great ideas:

- Use precision leveling systems to ensure your lathe is perfectly balanced.

- Install advanced coolant systems to keep the lathe running smoothly.

- Choose digital readouts for accurate measurements while you work.

These changes can make a big difference. They help create products that are exact and reliable, leading to better work overall. Keep your lathe updated for top performance!

What innovations help improve lathe performance?

Technological advancements like CNC systems and automatic tool changers enhance lathe performance. They allow for quicker and more precise operations, making the workload lighter for users.

Conclusion

In summary, using a lathe requires precision leveling for accuracy. Proper coolant helps cool the metal and maintain quality. You should check your setup regularly to ensure everything runs smoothly. By understanding these key aspects, you can improve your metalworking projects. Explore more about lathes and their maintenance for better results in your work!FAQs

What Are The Best Practices For Leveling A Metal Lathe To Ensure Precision During Machining Operations?To level a metal lathe, start by placing a spirit level on the machine. Adjust the legs until the bubble is centered. Make sure the lathe is on a strong, flat surface. Check it again after tightening everything to ensure it’s still level. This helps your lathe work better and makes your parts more accurate.

How Does Coolant Selection Impact The Performance And Precision Of A Lathe During Metalworking?Choosing the right coolant is very important for using a lathe, which is a machine that shapes metal. Coolant helps keep the cutting tools cool and prevents them from getting too hot. When tools stay cool, they cut better and make cleaner shapes. This means your metal pieces will be more exact and not have rough edges. Good coolant also helps the lathe last longer.

What Tools And Methods Can Be Used To Check The Level Of A Metal Lathe For Optimal Accuracy?To check if your metal lathe is level, you can use a few simple tools. A bubble level is great for this. Place it on different parts of the lathe to see if the bubble is centered. You can also use a square tool to check for right angles. Lastly, measuring tapes help to compare different parts of the lathe.

How Can Improper Leveling Of A Lathe Affect The Quality Of Finished Parts And Overall Machining Tolerances?If a lathe isn’t leveled right, it can make parts that aren’t shaped correctly. You might end up with wobbly or uneven pieces. This happens because the machine can’t cut straight. It can also make it harder to control how thick or thin the part is, leading to mistakes. To make good parts, we always need to level the lathe properly.

What Are The Advantages Of Using Specific Types Of Coolant For Different Metals When Operating A Lathe?Using the right coolant helps us keep the metal cool and avoid damage. Some coolants work better with certain metals, like aluminum or steel. This makes the cutting easier and longer-lasting. Plus, the right coolant helps us get a smoother finish. Overall, it makes our work faster and safer!