Have you ever wondered how metal parts are made with such high accuracy? The secret often lies in lathe precision leveling. A metal lathe machine shapes materials like aluminum and steel with remarkable precision. But how can we make sure these machines work better?

Imagine a metal lathe that wobbles or tilts. It wouldn’t cut straight, right? That’s why leveling is so important. Properly leveling a lathe ensures every cut is just as perfect as the last. When a lathe is level, it can make parts that fit together flawlessly.

Here’s a fun fact: Did you know that even a small tilt can cause big problems in the final product? That’s why many machinists pay close attention to this detail. They want the best results, and so should you!

In this article, we’ll explore how lathe precision leveling can improve your metal lathe machine. We’ll share tips and tricks to help you get your machine just right. Ready to dive in? Let’s get started!

Lathe Precision Leveling For Your Metal Lathe Machine

Understanding Lathe Precision Leveling

Lathe precision leveling is crucial for metal lathe machines. This process ensures the machine is perfectly aligned. Proper alignment boosts accuracy and reduces wear over time. Did you know that an uneven lathe can lead to mistakes and wasted materials? Users can achieve better results and longer tool life by leveling their lathe. It’s an easy step that pays off greatly, helping to create smooth, precise parts every time. Mastering this can elevate your metalworking skills!Understanding Lathe Precision Leveling

Definition of lathe precision leveling. Importance of precision in metal lathe operations.Lathe precision leveling means making sure a metal lathe is perfectly straight and balanced. Why is this so important? Picture baking a cake; if your pan is tilted, you’ll end up with a lopsided dessert! Precision in metal lathe operations helps ensure that every cut is accurate and neat. This keeps parts fitting just right and keeps the machines running smoothly. Think of it as giving your lathe a spa day!

| Aspect | Importance |

|---|---|

| Accuracy | Ensures high-quality parts |

| Efficiency | Reduces waste and saves time |

| Longevity | Extends machine life |

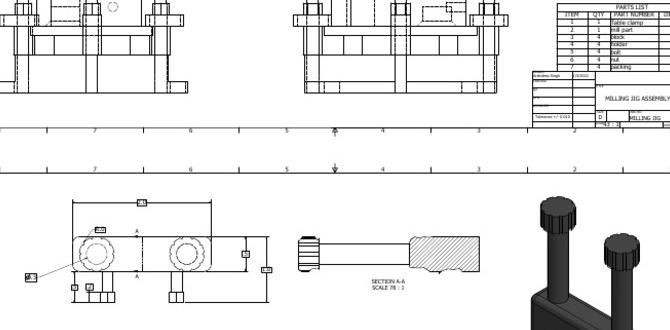

Tools Required for Leveling a Metal Lathe

List of necessary tools for leveling. Detailed description of each tool’s function.Leveling a metal lathe is important for accuracy. To do this, you need some handy tools. Here’s a list of what you will need:

- Leveling Feet: These are used to adjust the height of the lathe.

- Spirit Level: This tool checks if the lathe is perfectly horizontal.

- Dial Indicator: It measures small distances to help with precise adjustments.

- Wrenches: Wrenches help tighten or loosen screws and bolts.

Using these tools makes your lathe work better. It helps you create quality pieces easily.

What tools do I need to level my metal lathe?

You need leveling feet, spirit level, dial indicator, and wrenches for leveling your lathe.

Step-by-Step Guide to Leveling Your Lathe

Preparation steps before leveling. Detailed leveling procedure.Before you start leveling your lathe, gather your tools. You will need a level, some shims, and maybe a buddy to help. Safety first, right? Check the floor, too; make sure it’s clean and sturdy. This avoids hiccups during leveling. Once everything is set, the real fun begins!

Now, for the leveling procedure! Place the level on the lathe bed. Adjust the legs to get it perfectly straight. If it tilts, add shims where needed. Keep checking! It’s like a balancing act, but with less chance of falling. Once it’s level, tighten everything up. Voilà! Your lathe is ready for action!

| Step | Action |

|---|---|

| 1 | Clean the area |

| 2 | Check the floor stability |

| 3 | Place the level on the lathe |

| 4 | Adjust legs and add shims as needed |

| 5 | Tighten everything and double-check |

Common Mistakes to Avoid in Lathe Leveling

Frequent errors made during the process. Tips to troubleshoot and rectify issues.Many people make mistakes while leveling a lathe. Common errors include not checking the bed for bends and misaligning the tailstock. These issues can lead to mistakes in your work. Here are some tips to help you get it right:

- Always check the level of the lathe with a reliable level tool.

- Adjust the feet of the lathe until you reach proper alignment.

- Make sure the bed is clean and free from debris.

- Use a dial indicator for best accuracy.

If something doesn’t seem right, recheck your steps. Fixing mistakes early can save you time and effort later!

What are the common errors in lathe leveling?

Common errors include not ensuring the lathe is flat or aligning the tailstock poorly. These can cause poor cuts and finish. Always double-check your setup for best results.

Benefits of Proper Lathe Leveling

Enhanced accuracy and quality of workpieces. Increased lifespan of the lathe machine.Keeping your metal lathe machine level is like giving it a comfy bed. When you level it properly, you get better accuracy in your projects. This means fewer wobbles and mistakes. Plus, a well-leveled machine lasts longer! Think of it as a workout—less strain means your lathe stays strong and fit. Investing time in leveling is smart. Less hassle means more fun in your workshop. Who wouldn’t want their lathe to be happy?

| Benefits | Description |

|---|---|

| Enhanced Accuracy | Achieve precise cuts and shapes for quality workpieces. |

| Increased Lifespan | A properly leveled lathe endures more and serves you longer. |

Advanced Techniques for Professional Lathe Users

Techniques for optimizing lathe performance. Tools and gadgets available for advanced leveling.To boost your lathe’s performance, try advanced techniques. Start by ensuring your lathe is perfectly level. Use special leveling tools like electronic levels for accuracy. They help maintain straight cuts. Another great gadget is a depth gauge. This tool helps you measure cuts easily. Regularly check alignment, too. Good alignment leads to better results. Remember, small changes can make a big difference!

What tools help improve lathe performance?

Tools to enhance lathe performance include electronic levels and depth gauges. These gadgets help you measure and align accurately, leading to cleaner cuts.

Essential Gadgets:

- Electronic levels

- Depth gauges

- Alignment tools

Using these tools can transform your work. They help you achieve high-quality results every time!

Maintenance Tips for Maintaining Lathe Precision

Routine checks and adjustments. Longterm strategies for sustaining lathe accuracy.To keep your lathe working well, do regular checks. Look for loose parts and signs of wear. Adjust the settings as needed for smooth operation. Over time, use these long-term strategies to maintain accuracy:

- Clean the machine often to remove dust.

- Check alignments regularly to ensure precision.

- Replace worn-out parts quickly.

- Lubricate moving parts to prevent rust.

Taking these steps helps your metal lathe stay accurate. Remember, a well-maintained lathe works best.

How often should I check my lathe?

It’s best to check your lathe daily for small issues. Weekly checks can help you prevent bigger problems later.

Conclusion

In summary, lathe precision leveling is crucial for getting the best results from your metal lathe machine. Proper leveling ensures accuracy and helps avoid mistakes in your projects. By understanding and applying these techniques, you can improve your work quality. We encourage you to practice leveling your lathe machine and explore more resources to enhance your skills.FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling For Metal Lathe Machines:Sure! Here are some questions about leveling metal lathe machines: 1. Why is it important to level a lathe? Leveling a lathe helps it work better. If it is not level, it can make mistakes in cutting and shaping metal. 2. How can we check if a lathe is level? You can use a bubble level. Place it on the lathe bed and see if the bubble is in the center. 3. What tools do you need to level a lathe? You need a level tool, wrenches, and sometimes blocks or shims to adjust the legs of the lathe. 4. How often should you check the lathe’s level? You should check it whenever you move it or after a lot of use. Regular checks keep it working well. 5. Can we level a lathe ourselves? Yes, you can level a lathe yourself! Just follow the steps carefully and take your time.

Sure! Please provide the question you would like me to answer.

What Are The Essential Steps Involved In Leveling A Metal Lathe To Ensure Precision Machining?To level a metal lathe, first, find a flat surface where you want it to sit. Next, use a level tool to check if the lathe is straight. If it’s not, raise or lower the feet until it’s even. Then, double-check with the level tool to make sure it’s perfect. Finally, tighten everything up so it stays in place while you work.

How Does An Improperly Leveled Lathe Affect The Accuracy And Quality Of The Finished Parts?If a lathe is not level, it can cut parts unevenly. You might end up with wobbly or bumpy shapes. This happens because the machine can’t work properly. As a result, the parts may not fit together well. We want everything to be nice and smooth, so leveling is very important.

What Tools And Instruments Are Commonly Used To Achieve Precise Leveling Of A Lathe?To level a lathe, we commonly use some simple tools. You can use a level, which helps us see if the lathe is straight. We also use shims, which are small pieces of material that help lift parts of the lathe. Finally, we can use a straightedge to check if everything is even. These tools help ensure the lathe works well!

How Often Should A Metal Lathe Be Re-Leveled, And What Factors Influence This Frequency?You should re-level a metal lathe when you notice any changes in its accuracy. Factors that influence this include moving the lathe, heavy use, and temperature changes. If it gets bumped or shifted, check the level. Regular checks help keep your work precise and easy.

What Are The Signs That Indicate A Lathe Needs To Be Leveled Or Re-Leveled For Optimal Performance?You might notice uneven cuts in the wood or metal. If the machine shakes or vibrates a lot, that’s another sign. You could also see the tools wearing out faster than usual. Finally, if the lathe feels wobbly, it may need to be leveled again. All these signs mean you need to check if it’s sitting flat.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling For Metal Lathe Machines:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about leveling metal lathe machines: 1. Why is it important to level a lathe? Leveling a lathe helps it work better. If it is not level, it can make mistakes in cutting and shaping metal. 2. How can we check if a lathe is level? You can use a bubble level. Place it on the lathe bed and see if the bubble is in the center. 3. What tools do you need to level a lathe? You need a level tool, wrenches, and sometimes blocks or shims to adjust the legs of the lathe. 4. How often should you check the lathe’s level? You should check it whenever you move it or after a lot of use. Regular checks keep it working well. 5. Can we level a lathe ourselves? Yes, you can level a lathe yourself! Just follow the steps carefully and take your time.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Steps Involved In Leveling A Metal Lathe To Ensure Precision Machining? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, first, find a flat surface where you want it to sit. Next, use a level tool to check if the lathe is straight. If it’s not, raise or lower the feet until it’s even. Then, double-check with the level tool to make sure it’s perfect. Finally, tighten everything up so it stays in place while you work.”}},{“@type”: “Question”,”name”: “How Does An Improperly Leveled Lathe Affect The Accuracy And Quality Of The Finished Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe is not level, it can cut parts unevenly. You might end up with wobbly or bumpy shapes. This happens because the machine can’t work properly. As a result, the parts may not fit together well. We want everything to be nice and smooth, so leveling is very important.”}},{“@type”: “Question”,”name”: “What Tools And Instruments Are Commonly Used To Achieve Precise Leveling Of A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a lathe, we commonly use some simple tools. You can use a level, which helps us see if the lathe is straight. We also use shims, which are small pieces of material that help lift parts of the lathe. Finally, we can use a straightedge to check if everything is even. These tools help ensure the lathe works well!”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Be Re-Leveled, And What Factors Influence This Frequency? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should re-level a metal lathe when you notice any changes in its accuracy. Factors that influence this include moving the lathe, heavy use, and temperature changes. If it gets bumped or shifted, check the level. Regular checks help keep your work precise and easy.”}},{“@type”: “Question”,”name”: “What Are The Signs That Indicate A Lathe Needs To Be Leveled Or Re-Leveled For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might notice uneven cuts in the wood or metal. If the machine shakes or vibrates a lot, that’s another sign. You could also see the tools wearing out faster than usual. Finally, if the lathe feels wobbly, it may need to be leveled again. All these signs mean you need to check if it’s sitting flat.”}}]}