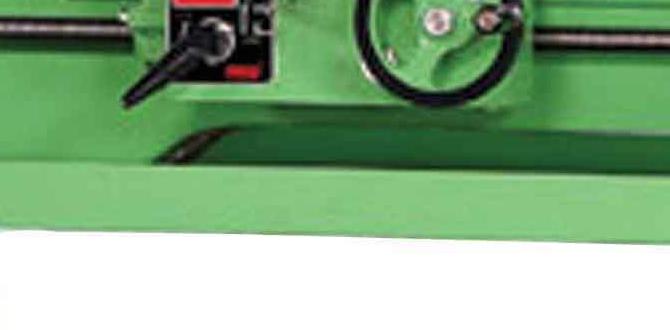

Have you ever wondered how a metal lathe works? Imagine a powerful machine that shapes metal into smooth pieces. But to get the best results, you need to make sure it is level. This is where lathe precision leveling comes in.

When a metal lathe is unlevel, it can create problems. You might end up with uneven cuts or strange vibrations. Have you experienced these troubles while working on a project? Precision leveling helps avoid these issues.

Now, let’s talk about the motor. The metal lathe motor drives the machine. If the motor doesn’t run well, the results won’t be great either. It might surprise you to know that leveling the lathe can improve the motor’s performance.

Join us as we explore the fascinating world of lathe precision leveling and metal lathe motors. Learn how small adjustments can make a big difference in your work. Ready to get started on your journey to perfecting your metal projects?

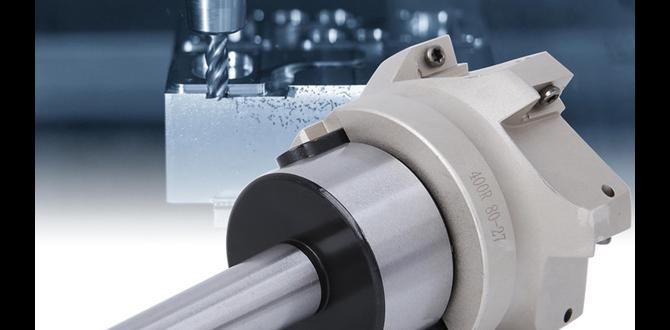

Lathe Precision Leveling: Metal Lathe Motor Insights

Lathe Precision Leveling: Metal Lathe Motor Insights

Precision is everything in metalworking. Lathe precision leveling ensures your lathe operates smoothly, producing accurate cuts. A well-leveled lathe motor can improve the quality of your projects and extend the life of the machine. Did you know that even a tiny tilt can lead to errors? Proper leveling keeps your work consistent and helps avoid frustrating mistakes. Understanding these key aspects can make your machining tasks more enjoyable and successful!Understanding Lathe Precision Leveling

Definition of lathe precision leveling. Importance of precision leveling in metalworking.Precision leveling means making sure a lathe is perfectly balanced and straight. This is very important in metalworking. If a lathe isn’t level, it can cause mistakes. For example, parts may be cut unevenly. Here are some reasons why it matters:

- Improved accuracy: A level lathe makes cleaner cuts.

- Better quality: Products made will last longer.

- Less wear: Machines last longer when they are level.

By keeping your lathe level, you help your work be the best it can be!

Why is Lathe Precision Leveling Important?

Lathe precision leveling ensures that all cuts are even and accurate. This leads to higher quality products, improving overall work efficiency.

Essential Tools for Lathe Leveling

Listing and describing necessary leveling tools. Tips for selecting the right tools for your lathe.To achieve perfect lathe leveling, you need the right tools. First, a spirit level helps you see if the lathe is balanced. Then, a dial indicator shows tiny height differences—perfect for precision. A straightedge is handy to check flat surfaces. When choosing tools, ensure they are durable and accurate. Remember, a tool that doesn’t measure up might as well be a rubber chicken!

| Tool | Description |

|---|---|

| Spirit Level | Checks if your lathe is perfectly balanced. |

| Dial Indicator | Measures small height changes for accuracy. |

| Straightedge | Ensures flat surfaces are really flat. |

With the right leveling tools, your lathe can achieve its full potential. Happy turning!

Step-by-Step Guide to Leveling Your Metal Lathe

Detailed procedure for leveling a metal lathe. Common mistakes to avoid during the leveling process.Leveling your metal lathe is important for accuracy. Follow these steps for better results:

- Check your lathe’s location. It should be on a solid floor.

- Use a level tool. Place it on the bed of the lathe.

- Adjust the feet. Raise or lower them to make the lathe level.

- Double-check the level. Move the level to different spots on the lathe.

Avoid these common mistakes:

- Neglecting to clean the area before leveling.

- Forgetting to recheck after adjustments.

- Taking too long to adjust levels, which might cause misalignment.

What tools do you need to level a metal lathe?

You’ll need a level tool, a wrench for adjustments, and a tape measure for checking distances. Make sure you have all tools ready to avoid interruptions.

Impact of Lathe Leveling on Motor Performance

How precision leveling affects motor efficiency. Relationship between leveling and product quality.Precision leveling is key for motor efficiency. When a lathe is not level, the motor has to work harder. This can lead to wear and tear over time. Better leveling means smoother operations and less energy use. The quality of the products also improves. If the lathe is level, cuts are cleaner and more accurate.

- Efficient motors last longer.

- Improved product quality enhances customer satisfaction.

- Less waste from mistakes saves materials.

How does leveling affect motor efficiency?

Leveling reduces strain on the motor, leading to better performance. Proper leveling can save up to 10% on energy costs and double the lifespan of the motor!

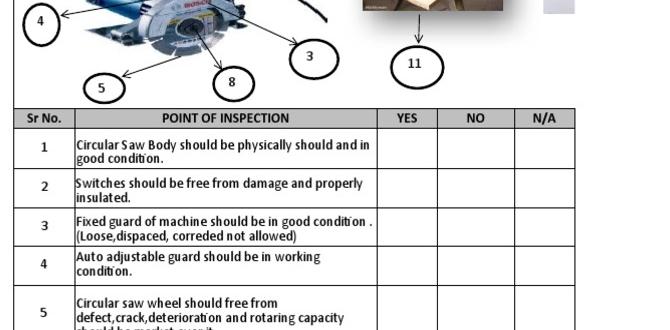

Diagnosing Lathe Leveling Issues

Identifying signs of poor leveling. Troubleshooting common problems associated with lathe motors.Poor leveling of your lathe can cause many problems. You might notice uneven cuts or vibrations. These signs tell you something is wrong. Check the following common issues with your lathe motor:

- **Vibration during operation**

- **Inconsistent cutting depth**

- **Unusual noise from the motor**

- **Failure to start or sudden stops**

Fixing these problems may need simple adjustments. Always ensure your lathe stands on a flat surface. If issues remain, consult a professional for help.

How do I know if my lathe is leveled properly?

Look for signed uneven cuts or strange sounds. If your lathe vibrates or behaves oddly, it likely needs leveling. Regular checks can save time and prevent costly repairs.

Advanced Techniques for Enhanced Lathe Leveling

Innovative methods and technologies for precision leveling. Adjusting for environmental factors affecting lathe performance.Getting your lathe in tip-top shape is no laughing matter, but that doesn’t mean it can’t be fun! Advanced techniques like using laser levels can make precision leveling a breeze. These nifty tools help ensure your lathe is as flat as the pancake you had for breakfast. Don’t forget to adjust for sneaky environmental factors too, like temperature changes and vibrations. They can mess with your lathe’s performance. Keep your workspace stable, and your lathe will thank you!

| Environmental Factors | Impact on Performance |

|---|---|

| Temperature | Can cause metal expansion or contraction |

| Vibrations | Lead to inaccuracies in machining |

Maintenance Tips for Long-Term Precision Leveling

Regular checks and adjustments to maintain leveling. Recommended maintenance practices for metal lathe motors.To keep your lathe running well, regular checks and small adjustments are key. Check the level every few weeks. Look for any changes in the machine’s position. Make sure the metal lathe motor is clean, and lubricate the moving parts often. This helps prevent wear and tear. Here are some great tips:

- Inspect belts and pulleys regularly.

- Look for signs of rust or wear.

- Clean dust and debris from the motor.

- Adjust leveling feet if necessary.

Case Studies: Successful Lathe Leveling Implementations

Realworld examples showcasing the benefits of precision leveling. Lessons learned from businesses that improved performance through proper leveling.Many companies have seen great results from precision leveling of their lathes. For example, a local machine shop improved their output by 30% after leveling their lathe precisely. This allowed them to produce parts faster and with fewer errors. Another factory noticed fewer machine breakdowns, leading to less downtime. Their productivity increased significantly. Key lessons learned include:

- Leveling reduces wear on equipment.

- Proper setup saves time and money.

- Consistent quality improves customer satisfaction.

What are the benefits of precision lathe leveling?

Precision lathe leveling leads to better accuracy and fewer mistakes. Machines work smoothly, which means less wear and tear, saving money long-term.

Conclusion

In conclusion, precise leveling of a metal lathe motor is crucial for accuracy. It helps you achieve smooth cuts and perfect finishes. Always check your lathe’s level before starting a project. This simple step can save you time and materials. For more tips and details, consider reading further about lathe maintenance and setup practices. Happy machining!FAQs

What Are The Best Techniques For Achieving Precision Leveling On A Metal Lathe?To achieve precision leveling on a metal lathe, you should start by placing the lathe on a strong, flat surface. Next, use a leveling tool to check if the lathe is even. Adjust the legs or feet of the lathe until it is perfectly level. Also, make sure to tighten all bolts after leveling to keep it steady. Lastly, double-check your work to ensure it stays level before you begin using the lathe.

How Does The Motor’S Alignment Impact The Overall Accuracy And Performance Of A Lathe?The motor’s alignment affects how well a lathe works. If the motor is straight, it helps the lathe spin smoothly. This means our cuts will be more precise and even. If the motor is off, we might get wobbly lines and mistakes. In short, a well-aligned motor helps us create better projects.

What Tools Or Instruments Are Recommended For Checking The Level Of A Lathe Setup?To check if a lathe is level, you can use a few simple tools. A spirit level helps you see if the lathe is straight. A ruler can help measure if the height is even on both sides. You can also use a dial indicator for precise checks. These tools make sure your lathe works well and cuts properly.

How Often Should A Metal Lathe Be Leveled, And What Factors Might Necessitate More Frequent Adjustments?You should level a metal lathe whenever you move it or if it seems off. You might need to adjust it more often if the floor is uneven or if heavy equipment shakes the lathe. Changes in temperature or humidity can also make it go out of level. Keep an eye on it to make sure it stays accurate!

What Common Mistakes Should Be Avoided When Leveling A Lathe To Ensure Optimal Machining Results?When leveling a lathe, we should avoid a few common mistakes. First, don’t forget to check the floor surface. If it’s uneven, the lathe won’t be straight. Second, make sure you use a level tool correctly. A mistake here can lead to bad cuts. Lastly, always double-check your adjustments. This helps ensure your lathe is set up right for good work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Best Techniques For Achieving Precision Leveling On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To achieve precision leveling on a metal lathe, you should start by placing the lathe on a strong, flat surface. Next, use a leveling tool to check if the lathe is even. Adjust the legs or feet of the lathe until it is perfectly level. Also, make sure to tighten all bolts after leveling to keep it steady. Lastly, double-check your work to ensure it stays level before you begin using the lathe.”}},{“@type”: “Question”,”name”: “How Does The Motor’S Alignment Impact The Overall Accuracy And Performance Of A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The motor’s alignment affects how well a lathe works. If the motor is straight, it helps the lathe spin smoothly. This means our cuts will be more precise and even. If the motor is off, we might get wobbly lines and mistakes. In short, a well-aligned motor helps us create better projects.”}},{“@type”: “Question”,”name”: “What Tools Or Instruments Are Recommended For Checking The Level Of A Lathe Setup? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if a lathe is level, you can use a few simple tools. A spirit level helps you see if the lathe is straight. A ruler can help measure if the height is even on both sides. You can also use a dial indicator for precise checks. These tools make sure your lathe works well and cuts properly.”}},{“@type”: “Question”,”name”: “How Often Should A Metal Lathe Be Leveled, And What Factors Might Necessitate More Frequent Adjustments? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should level a metal lathe whenever you move it or if it seems off. You might need to adjust it more often if the floor is uneven or if heavy equipment shakes the lathe. Changes in temperature or humidity can also make it go out of level. Keep an eye on it to make sure it stays accurate!”}},{“@type”: “Question”,”name”: “What Common Mistakes Should Be Avoided When Leveling A Lathe To Ensure Optimal Machining Results?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When leveling a lathe, we should avoid a few common mistakes. First, don’t forget to check the floor surface. If it’s uneven, the lathe won’t be straight. Second, make sure you use a level tool correctly. A mistake here can lead to bad cuts. Lastly, always double-check your adjustments. This helps ensure your lathe is set up right for good work.”}}]}