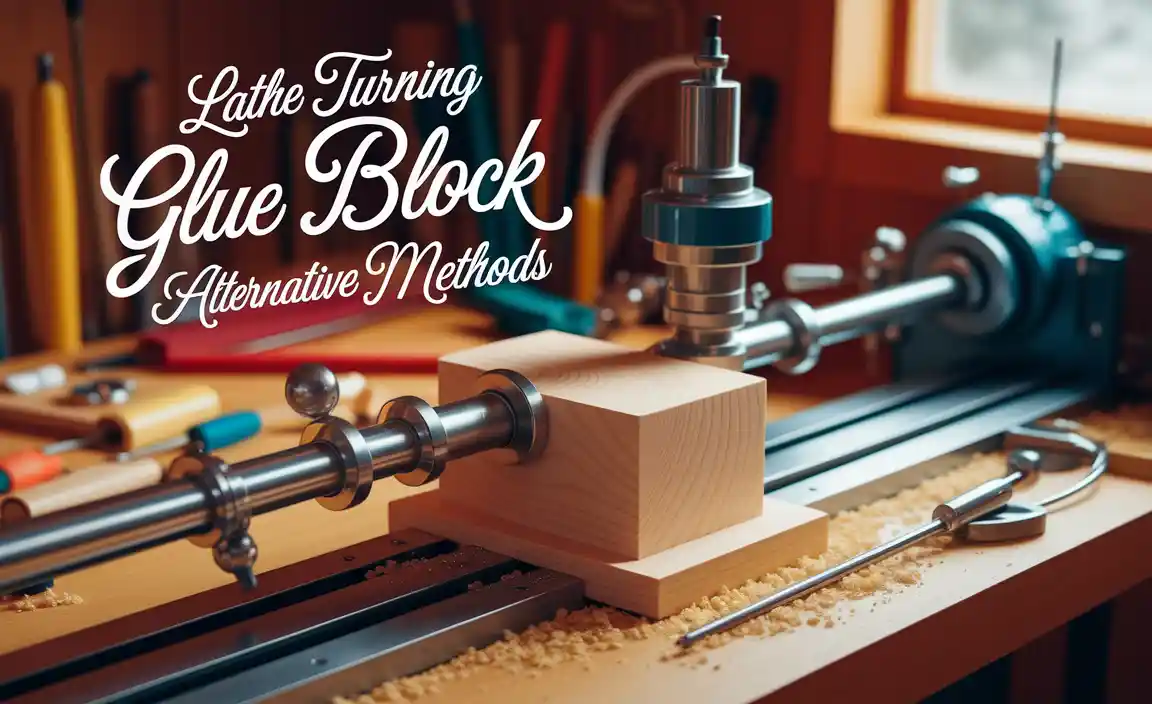

Have you ever wondered how some metal projects look so perfect? The secret often lies in lathe precision leveling. It’s a skill that can change your experience with metal lathes. When you set up a lathe correctly, your projects will come out amazing.

Imagine taking a block of metal and turning it into a finely crafted part. But what if it doesn’t sit right? Your project could end up lopsided or even unusable. That’s where leveling comes in. It helps you create better projects from the start.

Fun fact: Did you know that a well-leveled lathe can improve your cutting accuracy by up to 50%? That’s a big difference! By learning how to level your machine, you can take your metal lathe projects to a whole new level.

Join us as we explore the art of lathe precision leveling. You’ll discover tips and techniques that will make your metalworking experience not just easier, but much more enjoyable.

Lathe Precision Leveling For Metal Lathe Projects

Lathe Precision Leveling for Metal Projects

Precision leveling is key to successful metal lathe projects. It ensures your lathe operates smoothly and produces accurate pieces. Did you know that a perfectly leveled lathe can greatly reduce wear and tear? When setting up, check the level at multiple points. This simple step can save time and materials. Engaging in precise leveling also enhances your skills and confidence. As you work, you’ll notice how small adjustments lead to perfect finishes on your projects. Why not start leveling today?Understanding Lathe Precision Leveling

Definition of lathe precision leveling. Importance of precision leveling in metalworking.Lathe precision leveling is the process of making sure a lathe machine is perfectly flat and even. This is crucial for creating smooth and accurate metal parts. If the lathe is uneven, the parts may not fit together well. Good leveling helps achieve quality work and saves time and material.

- Creates accurate measurements

- Improves work quality

- Reduces material waste

Why is precision leveling important?

Precision leveling is important because it leads to better quality work, less waste, and ensures parts fit as intended. Good leveling can ultimately lead to safer and more efficient metalworking projects.

Tools and Equipment for Precision Leveling

Essential tools needed for leveling a lathe. Recommended brands and models for accuracy.To level your lathe with precision, you need some essential tools in your toolbox. Start with a good leveling kit, including a precision level and feeler gauges. These can help measure any tiny gaps and ensure everything is flat as a pancake! Recommended brands like Starrett and Mitutoyo are great for accuracy. Want to know the best tools? Check out the table below!

| Tool | Recommended Brand | Why It’s Great |

|---|---|---|

| Precision Level | Starrett | Very accurate! |

| Feeler Gauges | Mitutoyo | Perfect for finding gaps! |

| Dial Indicator | Brown & Sharpe | Measures tiny movements! |

Step-by-Step Guide to Leveling Your Lathe

Detailed process of leveling a lathe efficiently. Common mistakes to avoid during leveling.Leveling your lathe is key for great projects. Start by checking if the lathe is on a solid surface. Use a level tool for best results. Adjust its feet until it’s perfectly horizontal. Remember, slight differences can lead to big mistakes. Avoid these common errors:

- Skipping the initial surface check.

- Not adjusting feet equally.

- Over-tightening adjustments.

Take your time. Even small tweaks matter. Enjoy your work and stay safe!

Why is Lathe Leveling Important?

Leveling your lathe ensures accuracy and quality in your projects. A misaligned lathe can cause uneven cuts and poor finishes.

Factors Affecting Lathe Precision

Environmental factors influencing lathe performance. Mechanical factors to consider for optimal precision.Many things can influence how well a lathe works. Environmental factors are important. For example, dirt and temperature can affect precision. If it’s too hot or cold, machines don’t work as well. Mechanical factors also matter. Worn parts can lead to mistakes. Keeping parts in good shape helps keep everything precise. Here are some main points to remember:

- Dust and dirt can make machines less accurate.

- Temperature changes can cause metal to expand or shrink.

- Worn or loose parts need replacement for correct performance.

What environmental issues affect lathe performance?

Temperature, humidity, and cleanliness are key environmental issues. They can change how a lathe operates. For example, too much dirt can damage the machinery.

How do mechanical factors impact precision?

Mechanical factors like wear and tear can reduce precision. If parts are worn out, they need replacement to keep everything working smoothly.

Common Metal Lathe Projects Requiring Precision Leveling

Examples of projects demanding high precision. Tips for achieving precision in specific projects.Creating metal lathe projects that need precision is like baking a cake—get it wrong, and you end up with a mess! Projects like gear manufacturing or shaft production demand accurate leveling. To ensure success, check each setup carefully. Use a leveling tool to avoid wobbling. Remember, a straight shaft is nobody’s cakewalk, and a twisty one? Well, that’s just trouble!

| Project | Precision Tips |

|---|---|

| Gear Manufacturing | Use a dial indicator to check for level. |

| Shaft Production | Align centers using a laser for accuracy. |

| Custom Tooling | Keep your tools sharp for the best results! |

Maintenance and Calibration for Longevity

Routine maintenance practices for continued accuracy. Calibration techniques to ensure longterm precision.Keeping your metal lathe in tip-top shape is like feeding a pet — it needs regular care! For accuracy, routine maintenance is key. Check all moving parts for wear and tear. A little oil goes a long way, but too much can make things slippery, like trying to dance on ice!

Calibration is also crucial. Measuring tools often help maintain precision. A good rule is to check your lathe’s accuracy every few months. Remember, “A lathe that isn’t calibrated is like a joke without a punchline!”

| Maintenance Tips | Calibration Techniques |

|---|---|

| Inspect moving parts regularly | Use measuring tools monthly |

| Lubricate to prevent rust | Recheck settings every few months | Clean after each use | Make notes of any changes |

Follow these steps, and your lathe will be ready for all those precision projects ahead!

Advanced Techniques for Precision Leveling

Innovative methods and technologies in leveling. Case studies showcasing successful advanced leveling projects.Imagine leveling your metal lathe like a pro! With new methods and cool tools, precision leveling can feel like magic. High-tech gadgets can help you achieve a level surface faster than you can say “lathe project”. For example, laser leveling tools make it easy to get everything just right. And let’s not forget the success stories! Some projects used these techniques and turned out perfectly. You really can’t ask for better results.

| Technique | Description | Success Case |

|---|---|---|

| Laser Leveling | Quick setup and super accurate | Title: “Metal Works: Precision Redefined” |

| Digital Tools | Real-time readings for perfect adjustments | Title: “Technological Triumph in Metal Lathe Projects” |

Using these innovative techniques, you can ace your leveling game! Who knew leveling could be this fun?

Conclusion

In summary, leveling your metal lathe is crucial for precision. It helps you create accurate projects and improves your skills. Always check your setup before starting. Practice makes perfect, so don’t hesitate to try new techniques. For more tips and project ideas, explore books or online resources. We can all become better creators together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Metal Lathe Projects:Sure! Here are five simple questions about lathe precision leveling and metal lathe projects. 1. Why is leveling a lathe important? Leveling helps the lathe work properly. If it’s not level, it can create bad cuts. 2. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins metal while cutting tools shape it. 3. How do you level a lathe? You use a leveling tool. You adjust the machine’s feet until it stays even. 4. What kind of projects can you make with a lathe? With a lathe, you can make things like toys, tools, or parts for machines. 5. Can beginners use a lathe? Yes, beginners can use a lathe! It’s fun to learn and create new things with it.

Of course! Please share the question you would like me to answer.

What Are The Best Practices For Leveling A Metal Lathe To Ensure Maximum Precision In Machining Operations?To level a metal lathe, first check the floor. It should be solid and not wobbly. Next, use a level tool on top of the lathe. Adjust the feet until the lathe is perfectly flat. Finally, double-check with the level to make sure it stays even. This helps you make precise parts!

How Does The Leveling Of A Lathe Impact The Accuracy Of Turned Parts And What Tools Can Be Used For Precise Leveling?Leveling a lathe helps it work correctly. If it’s not level, the parts we make can be uneven. We want our turned parts to be just right! To level a lathe, you can use a machinist’s level or a bubble level. These tools show if the lathe is straight or tilted.

What Common Issues Arise From An Improperly Leveled Lathe, And How Can They Affect The Quality Of A Metal Lathe Project?If a lathe is not leveled right, it can cause several problems. You might get uneven cuts, which means the metal piece won’t look or fit well. It could also lead to vibrations, making it hard to control. When this happens, your project might end up weak or not work as it should. Keeping the lathe level helps you make better projects!

What Are Some Innovative Projects That Can Be Created Using A Precision Leveled Metal Lathe, And What Complexities Do They Involve?You can use a precision leveled metal lathe to make cool things like toy car parts or custom tools. These projects require measuring carefully and using the machine safely. You need to know how to set up the lathe right to cut the metal correctly. Sometimes, you might have to fix mistakes, which can be tricky. But with practice, you can create awesome items!

How Frequently Should A Metal Lathe Be Checked And Recalibrated For Precision Leveling, Especially In A Production Environment?You should check a metal lathe every week if you use it a lot. If you notice any problems, check it right away. It’s important to calibrate it monthly to keep it precise. Regular checks help us make better parts. Always keep an eye on it for the best results!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision Leveling And Metal Lathe Projects:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five simple questions about lathe precision leveling and metal lathe projects. 1. Why is leveling a lathe important? Leveling helps the lathe work properly. If it’s not level, it can create bad cuts. 2. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins metal while cutting tools shape it. 3. How do you level a lathe? You use a leveling tool. You adjust the machine’s feet until it stays even. 4. What kind of projects can you make with a lathe? With a lathe, you can make things like toys, tools, or parts for machines. 5. Can beginners use a lathe? Yes, beginners can use a lathe! It’s fun to learn and create new things with it.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please share the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Leveling A Metal Lathe To Ensure Maximum Precision In Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a metal lathe, first check the floor. It should be solid and not wobbly. Next, use a level tool on top of the lathe. Adjust the feet until the lathe is perfectly flat. Finally, double-check with the level to make sure it stays even. This helps you make precise parts!”}},{“@type”: “Question”,”name”: “How Does The Leveling Of A Lathe Impact The Accuracy Of Turned Parts And What Tools Can Be Used For Precise Leveling?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Leveling a lathe helps it work correctly. If it’s not level, the parts we make can be uneven. We want our turned parts to be just right! To level a lathe, you can use a machinist’s level or a bubble level. These tools show if the lathe is straight or tilted.”}},{“@type”: “Question”,”name”: “What Common Issues Arise From An Improperly Leveled Lathe, And How Can They Affect The Quality Of A Metal Lathe Project?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a lathe is not leveled right, it can cause several problems. You might get uneven cuts, which means the metal piece won’t look or fit well. It could also lead to vibrations, making it hard to control. When this happens, your project might end up weak or not work as it should. Keeping the lathe level helps you make better projects!”}},{“@type”: “Question”,”name”: “What Are Some Innovative Projects That Can Be Created Using A Precision Leveled Metal Lathe, And What Complexities Do They Involve?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use a precision leveled metal lathe to make cool things like toy car parts or custom tools. These projects require measuring carefully and using the machine safely. You need to know how to set up the lathe right to cut the metal correctly. Sometimes, you might have to fix mistakes, which can be tricky. But with practice, you can create awesome items!”}},{“@type”: “Question”,”name”: “How Frequently Should A Metal Lathe Be Checked And Recalibrated For Precision Leveling, Especially In A Production Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check a metal lathe every week if you use it a lot. If you notice any problems, check it right away. It’s important to calibrate it monthly to keep it precise. Regular checks help us make better parts. Always keep an eye on it for the best results!”}}]}