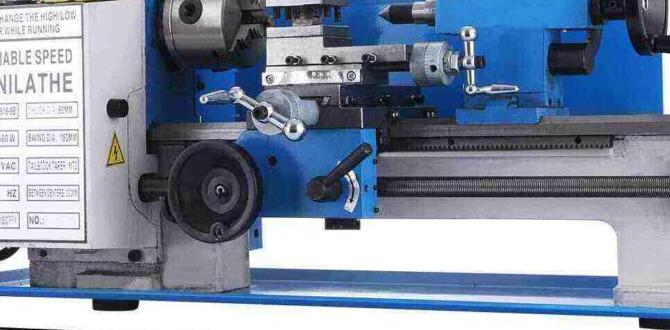

Have you ever watched a lathe at work? It’s like watching magic happen in a workshop. A metal lathe spins materials to shape them into smooth, precise parts. But to make sure it works well, you must focus on something important: precision leveling.

Imagine trying to balance a ball on the tip of your finger. It takes skill and care; otherwise, it falls. The same idea applies to a lathe. If it’s not level, the results can be messy. You might face issues that stop your project in its tracks.

Have you experienced strange noises or uneven cuts from a lathe? It can be frustrating, right? Many people don’t realize that troubleshooting issues often starts with proper leveling. The good news is that once you understand lathe precision leveling, you can solve these problems quickly.

Join us as we explore the ins and outs of leveling your metal lathe. Get ready to learn tips that will make your projects smoother and more enjoyable. After all, the right setup can bring your creativity to life!

Lathe Precision Leveling: Metal Lathe Troubleshooting Tips

Lathe Precision Leveling and Metal Lathe Troubleshooting

Understanding lathe precision leveling helps improve your machining skills. Proper leveling ensures accurate cuts and quality results. Did you know that a small adjustment can make a big difference? When troubleshooting a metal lathe, examine the bed’s level, the offset of the tailstock, and the condition of tools. Taking a few minutes to check these factors can save hours of frustration. Enjoy smoother operations with your lathe by knowing how to fix common issues effectively!Understanding Lathe Precision Leveling

Importance of precision leveling in metalworking. Tools required for accurate leveling.Precision leveling is crucial in metalworking. It ensures your lathe operates smoothly and accurately. When your machine is level, it reduces errors and material waste. You want your projects to succeed, right? No one likes a wobbly lathe! To achieve this, you’ll need a few simple tools. A level, measuring tape, and some shims are your best friends. With these tools, you can get your lathe as straight as an arrow—no archery skills required!

| Tool | Purpose |

|---|---|

| Level | Checks if the lathe is even |

| Measuring Tape | Measures distances for accuracy |

| Shims | Helps adjust height and level |

Keep in mind, proper leveling can boost your machine’s lifespan. So, treat your lathe right, and it will treat you right too!

Common Issues with Metal Lathes

Identifying signs of improper leveling. Impact of misalignment on machining accuracy.Metal lathes can be tricky, and leveling them is key for smooth operation. If your workpieces have odd bumps or uneven cuts, you might have a leveling problem. Misalignment throws off machining accuracy, making your projects look more like art abstract rather than masterpieces. Imagine trying to cut a sandwich evenly while standing on one leg—messy, right? Here’s a table that shows some common signs of improper leveling:

| Signs of Improper Leveling | Impact on Accuracy |

|---|---|

| Uneven surfaces | Leads to wavy cuts |

| Excessive vibration | Causes misalignment |

| Workpiece movement | Results in dimensional errors |

Addressing these issues early saves time and keeps your projects from resembling a lopsided pancake. Remember, a little leveling can go a long way!

Step-by-Step Guide to Leveling Your Lathe

Preleveling checks and preparations. Detailed leveling procedures.Before leveling your lathe, be sure to check a few important things. Make sure the floor is strong and even. Remove any clutter around your workspace. It’s also crucial to inspect the lathe itself for damage or wear. Proper preparation can save you time and effort.

Now for the leveling process, follow these steps:

- Place a level on the lathe bed.

- Adjust the feet of the lathe to level it.

- Recheck with the level after adjustments.

- Repeat until the lathe is stable.

Make sure the lathe is perfectly level for accurate work. Leveling helps avoid issues during operation.

What should I check before leveling my lathe?

Before leveling your lathe, check the floor for flatness, remove clutter, and inspect the machine for any damage.

Troubleshooting Lathe Performance Problems

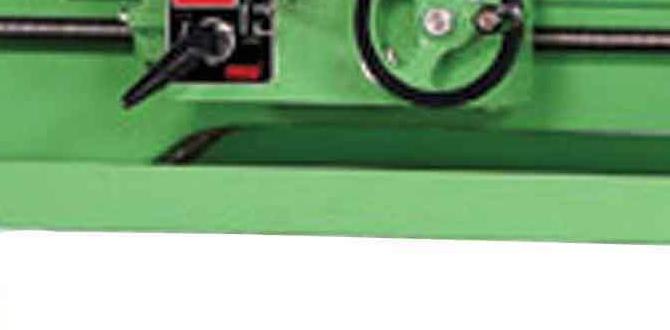

Common symptoms of lathe issues. Quick fixes for mechanical and electrical problems.Lathe problems can show up in many ways. Some common signs include strange noises, poor cuts, or vibrations. These issues can frustrate users. Luckily, there are quick fixes you can try. Check the belts for wear and ensure they fit snugly. Make sure the electrical connections are tight. If the machine is still not working, consult the manual for guidance.

What are the common symptoms of lathe issues?

Common symptoms include:

- Strange noises during operation

- Poor quality cuts

- Excessive vibration

- Difficulty starting the machine

What are quick fixes for mechanical and electrical problems?

Quick fixes include:

- Inspecting belts for wear

- Checking electrical connections

- Lubricating moving parts

- Tightening loose bolts

Advanced Techniques for Precision Adjustment

Finetuning alignment for optimal performance. Utilizing digital leveling tools.To improve the performance of your lathe, focus on finetuning the alignment. This ensures every cut is smooth and precise. You can use digital leveling tools to measure adjustments accurately. Here are some tips:

- Check the bed for any leveling issues.

- Adjust tailstock and headstock alignment.

- Use digital tools for quick readings.

This way, you can work more efficiently, making your projects easier and more enjoyable!

What are tips for using digital leveling tools?

Use a bubble level or digital gauge to check angles easily. Make small adjustments for best results. Always double-check your work!

Maintenance Tips for Prolonging Lathe Life

Regular inspection and maintenance schedules. Best practices for keeping a lathe in top shape.To keep your lathe buzzing happily, regular check-ups are a must! How often? Think of it like brushing your teeth—at least every six months! Keep an eye on parts for wear and tear. You wouldn’t want your lathe to complain or break down, right? Brush off dust and apply oil like a massage for metal. It’s a little TLC that goes a long way. Here are some quick tips:

| Maintenance Task | Frequency |

|---|---|

| Check Belt Tension | Monthly |

| Clean Surfaces | Weekly |

| Lubricate Parts | Every 3 months |

A little bit of love keeps your lathe from turning into a rusty dinosaur!

Frequently Asked Questions about Lathe Leveling and Troubleshooting

Clarifying common misconceptions. Expert answers to popular questions.Many people have questions about lathe leveling and troubleshooting. Misunderstandings can make it seem harder than it is. Here are some common questions with expert answers:

What is lathe leveling?

Lathe leveling means making sure the lathe machine is flat and steady. This helps it work better and make precise cuts.

Do I need to level my lathe often?

Yes, check your lathe regularly. Make sure it stays level, especially if you move it or if it’s in an area with vibrations.

Can uneven floors affect my lathe?

Yes! An uneven floor can cause problems. It can make your cuts inaccurate and lead to wear and tear.

How do I troubleshoot problems with my lathe?

- Check the level and adjust as needed.

- Look for worn parts.

- Make sure the motor is working well.

By knowing the facts, you can keep your lathe running smoothly.

Conclusion

In conclusion, understanding lathe precision leveling is crucial for smooth metal lathe operations. You can troubleshoot common issues by checking alignment, adjusting feet, and ensuring stability. Remember, a well-leveled lathe leads to better results. We encourage you to practice these tips and explore more resources on lathe maintenance. With time, you’ll become skilled in troubleshooting your lathe effectively!FAQs

What Are The Common Signs That Indicate A Metal Lathe Is Not Properly Leveled?If a metal lathe is not properly leveled, you might notice some signs. First, the machine may shake or vibrate while it works. You might also see that the metal isn’t cut evenly. Sometimes, the tool can dig too deep in one spot and not in others. Lastly, you could hear weird noises, like grinding, when it runs.

How Can I Accurately Check The Level Of My Metal Lathe Using A Spirit Level Or Digital Level?To check your metal lathe’s level, place the spirit level or digital level on the bed of the lathe. Look at the bubble in the spirit level; it should be in the middle. If you’re using a digital level, read the number. Adjust your lathe by raising or lowering the legs until it is level. Check again to make sure it’s just right!

What Steps Should I Follow To Troubleshoot And Correct Precision Issues Resulting From An Unlevel Lathe?To fix precision issues with an unlevel lathe, first check if the lathe is flat. You can use a spirit level to see if it’s even. If it’s not, adjust the feet or base until it is level. Next, tighten any loose screws or parts that might be causing problems. Finally, test your lathe again to see if it works better.

How Does The Leveling Of A Lathe Impact The Accuracy Of Machining Operations, Such As Turning And Threading?When we level a lathe, it stands straight and true. This helps the machine cut evenly. If it’s not level, the cuts can be crooked or uneven. This makes things like turning and threading less accurate. So, keeping it level is very important for making good parts.

What Tools And Equipment Are Recommended For Maintaining And Leveling A Metal Lathe For Optimal Performance?To keep a metal lathe working well, you need some basic tools. A level helps make sure the lathe is flat. You also need wrenches for tightening parts. A measuring tape is good for checking distances. Finally, using oil keeps everything running smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Metal Lathe Is Not Properly Leveled? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If a metal lathe is not properly leveled, you might notice some signs. First, the machine may shake or vibrate while it works. You might also see that the metal isn’t cut evenly. Sometimes, the tool can dig too deep in one spot and not in others. Lastly, you could hear weird noises, like grinding, when it runs.”}},{“@type”: “Question”,”name”: “How Can I Accurately Check The Level Of My Metal Lathe Using A Spirit Level Or Digital Level? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check your metal lathe’s level, place the spirit level or digital level on the bed of the lathe. Look at the bubble in the spirit level; it should be in the middle. If you’re using a digital level, read the number. Adjust your lathe by raising or lowering the legs until it is level. Check again to make sure it’s just right!”}},{“@type”: “Question”,”name”: “What Steps Should I Follow To Troubleshoot And Correct Precision Issues Resulting From An Unlevel Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix precision issues with an unlevel lathe, first check if the lathe is flat. You can use a spirit level to see if it’s even. If it’s not, adjust the feet or base until it is level. Next, tighten any loose screws or parts that might be causing problems. Finally, test your lathe again to see if it works better.”}},{“@type”: “Question”,”name”: “How Does The Leveling Of A Lathe Impact The Accuracy Of Machining Operations, Such As Turning And Threading? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we level a lathe, it stands straight and true. This helps the machine cut evenly. If it’s not level, the cuts can be crooked or uneven. This makes things like turning and threading less accurate. So, keeping it level is very important for making good parts.”}},{“@type”: “Question”,”name”: “What Tools And Equipment Are Recommended For Maintaining And Leveling A Metal Lathe For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a metal lathe working well, you need some basic tools. A level helps make sure the lathe is flat. You also need wrenches for tightening parts. A measuring tape is good for checking distances. Finally, using oil keeps everything running smoothly.”}}]}