Have you ever wondered how to create perfect metal parts? Using a lathe can help you do just that. A mini metal lathe is a handy tool for many small projects. But did you know that precision leveling is key to getting the best results? Without proper leveling, your projects can go off track.

Imagine trying to build something amazing only to find it wobbles or isn’t straight. That’s frustrating! Precision leveling makes sure your lathe works just right. It helps you make parts that fit well and look great. Whether you are a hobbyist or just starting, knowing about lathe precision leveling can change your projects for the better.

Let’s dive into how to get your mini metal lathe set up perfectly. You’ll discover tips and tricks that can make a big difference in your work. Get ready to learn how to achieve smooth and accurate results every time!

Lathe Precision Leveling For Mini Metal Lathe Setup Guide

Lathe Precision Leveling Mini Metal Lathe

Using a lathe precision leveling mini metal lathe is essential for anyone into metalworking. This tool helps create accurate and smooth cuts. Imagine building a small robot or making custom parts for a school project. Proper leveling ensures that your machine works perfectly every time, boosting your confidence in crafting. Fun fact: did you know that miniature lathes can be just as powerful as larger ones? They’re versatile and perfect for hobbyists and pros alike!Understanding Lathe Precision Leveling

Definition of precision leveling and its importance in machining. Benefits of precision leveling in mini metal lathes.Precision leveling is about making sure a machine is perfectly straight and centered. This matters in machining because it helps create accurate and high-quality products. For mini metal lathes, precision leveling offers many benefits:

- Better product accuracy

- Less wear and tear on the machine

- Quieter operation

- Longer machine lifespan

When your lathe is level, it works better and makes your jobs easier. Remember, a small change can lead to big results!

What is the importance of precise leveling in metal lathes?

Precise leveling is crucial for achieving accuracy and efficiency in mini metal lathe machining. It ensures that each cut is smooth and true, reducing errors.

Why should you level your lathe?

- To achieve better finish quality

- To increase operational safety

- To ensure device accuracy over time

Maintaining level helps keep your projects on track!

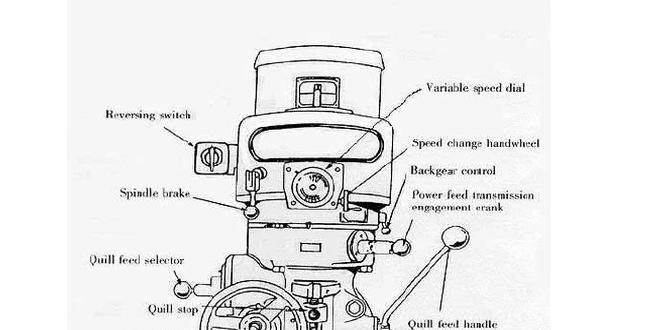

Essential Tools for Precision Leveling

List of tools required for leveling a mini metal lathe. How to select quality leveling tools.To level your mini metal lathe, you need some special tools. Here’s what you’ll want in your toolbox:

| Tool | Purpose |

|---|---|

| Leveling Bar | Helps find the right height, like a measuring stick for fairness. |

| Digital Level | Shows precise angles, making leveling easier (no math required!). |

| Shims | Fill gaps to stabilize the lathe. Think of them as little superheroes! |

Select quality tools by checking reviews and brands. Good tools make a big difference. A level lathe cuts better, so be picky! With the right gear, you’ll turn your lathe into a champion of precision!

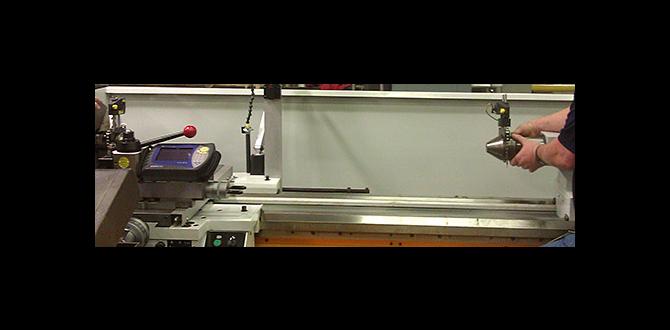

Step-by-Step Guide to Leveling Your Mini Metal Lathe

Detailed instructions on how to properly level a lathe. Common mistakes to avoid during the leveling process.Leveling your mini metal lathe is like setting up a fun game; you want everything just right to enjoy it! First, gather your tools, including a level and wrench. Next, check the machine’s base on a flat surface. Adjust the feet until it’s perfectly level. Avoid common mistakes like skipping the leveling process or not checking after adjustments—think of it like balancing a pizza on your hand! Remember, a well-leveled lathe makes better parts. Here’s a handy table to guide you:

| Step | Action | Common Mistakes |

|---|---|---|

| 1 | Check the base | Not using a flat surface |

| 2 | Adjust feet | Skipping measurements |

| 3 | Double-check level | Ignoring misalignment |

Follow these steps, and you’ll make your lathe sing! And remember, a happy lathe means happy projects!

Checking and Maintaining Lathe Leveling

How to regularly check the leveling of your lathe. Recommended maintenance practices for sustaining precision.Checking your lathe’s leveling often is a must for smooth operation. You can start by using a level tool on the machine bed. If the bubble wiggles like it’s dancing, time to adjust! Tightening or loosening the feet can help. For maintenance, clean the lathe regularly to keep it happy and running well. Lubricate the moving parts so they glide as smoothly as butter. Remember, a well-maintained lathe is like a well-fed cat—much easier to deal with!

| Maintenance Task | Frequency |

|---|---|

| Check Leveling | Weekly |

| Clean Machine | Monthly |

| Lubricate Parts | Monthly |

So, remember to keep an eye on your lathe! Regular checks can help you avoid inaccuracies that might make it behave like a cranky toddler. A well-maintained lathe not only lasts longer but also helps you avoid those pesky mishaps. Stay sharp, and your projects will turn out great!

Impact of Environmental Factors on Lathe Leveling

Discussion of how temperature, humidity, and vibration affect lathe precision. Tips for optimizing the workshop environment for better results.Lathe machines are sensitive little beasts. Temperature, humidity, and vibration can really throw a wrench in their precision! If it’s too hot or too cold, the metal parts can expand or contract. This leads to errors in your measurements. Humidity is like that pesky friend who keeps changing plans—too much moisture can cause rust! What about vibrations? They’re like a cat walking on your keyboard—super distracting!

To keep your lathe happy, optimize the workshop environment. Use a proper heater or air conditioner to stabilize temperature. Keep humidity around 30%-50%. And for vibrations, secure your lathe to a stable surface. It’s like giving it a warm hug! Remember, a comfy lathe makes for **better results!**

| Environmental Factor | Impact | Tip |

|---|---|---|

| Temperature | Can cause metal to expand/contract | Maintain a constant temperature |

| Humidity | Can lead to rust | Keep humidity between 30%-50% |

| Vibration | Affects cutting accuracy | Secure your lathe |

Common Issues and Troubleshooting

Identification of common levelingrelated problems in mini metal lathes. Solutions and tips for effectively troubleshooting these issues.Using a mini metal lathe can lead to some common leveling problems. Noticing these issues early helps you fix them quickly. Here are a few problems you might face:

- Uneven cuts

- Vibrations during operation

- Inaccurate measurements

To solve these issues:

- Check and adjust the base level.

- Tighten loose screws and bolts.

- Always clean your lathe.

Taking these steps will improve your lathe’s precision and performance.

What are common issues with mini metal lathes?

Common issues include uneven cuts, vibrations, and inaccuracy.

How to troubleshoot mini metal lathe problems?

To troubleshoot, check level, tighten parts, and clean your lathe.

Real-World Applications of Precision Leveling

Examples of industries that benefit from precise lathe leveling. Case studies showcasing successful implementations.Many industries benefit from precise lathe leveling. For example, the aerospace sector uses it to create parts that are super accurate. A small mistake can make a big difference in the air! The automotive industry also relies on this precision to produce smooth-running engines. A case study showed that a popular car company improved their production time by 30% just by leveling their lathes. Talk about a smooth ride!

| Industry | Benefit |

|---|---|

| Aerospace | High precision in parts |

| Automotive | Faster production times |

| Medical | Accurate instruments |

Conclusion

In conclusion, using a lathe for precision leveling improves your metalworking projects. A mini metal lathe is perfect for beginners and small tasks. You can achieve better accuracy and efficiency by leveling your lathe properly. Take time to learn about leveling techniques and practice regularly. Explore more resources online to enhance your skills and create amazing projects!FAQs

What Are The Key Factors To Consider When Leveling A Mini Metal Lathe For Optimal Precision?To level a mini metal lathe, we need to check a few important things. First, make sure the lathe sits on a solid, flat surface. We also need to use a bubble level to see if it’s straight. Adjust the feet of the lathe until the bubble is centered. Finally, tighten the screws so it won’t move when we use it.

How Can I Check The Accuracy Of My Lathe’S Leveling Before Starting A Machining Project?To check if your lathe is level, you can use a leveling tool. First, place the tool on the lathe bed. Then, look to see if the bubble is in the middle. If it is, your lathe is level. If not, you may need to adjust the feet of the lathe until it is.

What Tools Are Best Suited For Leveling A Mini Metal Lathe Accurately?To level a mini metal lathe accurately, you need a few tools. A spirit level helps you see if it’s straight. A dial indicator can check how level the lathe is from side to side. You might also use shims, which are small pieces of material to fill gaps. These tools will help you make sure your lathe is just right for work!

How Does The Leveling Of A Lathe Affect The Overall Quality Of The Machined Parts?When a lathe is level, it works better. It helps the cutting tools cut evenly. If the lathe is not level, it can create parts that are uneven or too big. This means you might need to fix things more often. A leveled lathe makes high-quality parts that fit together nicely.

What Common Mistakes Should Be Avoided During The Leveling Process Of A Mini Metal Lathe?When you level a mini metal lathe, avoid these mistakes. First, don’t forget to check if the machine is on a flat surface. Second, make sure all the feet are touching the ground evenly. Third, don’t rush; take your time to get it right. Lastly, always use a level tool to check your work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Leveling A Mini Metal Lathe For Optimal Precision? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a mini metal lathe, we need to check a few important things. First, make sure the lathe sits on a solid, flat surface. We also need to use a bubble level to see if it’s straight. Adjust the feet of the lathe until the bubble is centered. Finally, tighten the screws so it won’t move when we use it.”}},{“@type”: “Question”,”name”: “How Can I Check The Accuracy Of My Lathe’S Leveling Before Starting A Machining Project? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if your lathe is level, you can use a leveling tool. First, place the tool on the lathe bed. Then, look to see if the bubble is in the middle. If it is, your lathe is level. If not, you may need to adjust the feet of the lathe until it is.”}},{“@type”: “Question”,”name”: “What Tools Are Best Suited For Leveling A Mini Metal Lathe Accurately? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To level a mini metal lathe accurately, you need a few tools. A spirit level helps you see if it’s straight. A dial indicator can check how level the lathe is from side to side. You might also use shims, which are small pieces of material to fill gaps. These tools will help you make sure your lathe is just right for work!”}},{“@type”: “Question”,”name”: “How Does The Leveling Of A Lathe Affect The Overall Quality Of The Machined Parts? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When a lathe is level, it works better. It helps the cutting tools cut evenly. If the lathe is not level, it can create parts that are uneven or too big. This means you might need to fix things more often. A leveled lathe makes high-quality parts that fit together nicely.”}},{“@type”: “Question”,”name”: “What Common Mistakes Should Be Avoided During The Leveling Process Of A Mini Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you level a mini metal lathe, avoid these mistakes. First, don’t forget to check if the machine is on a flat surface. Second, make sure all the feet are touching the ground evenly. Third, don’t rush; take your time to get it right. Lastly, always use a level tool to check your work.”}}]}