Have you ever wondered how precision metal parts are made? It’s a fascinating process that combines skill and the right tools. One of the key machines used in this work is the lathe. This tool shapes metal into the perfect forms that industries depend on.

But what makes a lathe even better? The answer lies in the quick change tool post. This nifty device allows you to switch tools quickly without wasting time. Imagine being able to work faster and more accurately. That’s the magic of a quick change tool post on a lathe!

Did you know that using this tool can change how you create metal parts? Many craftsmen find that it boosts their productivity. So, whether you are a beginner or an expert, understanding this tool can help you make amazing things.

Join us as we explore how lathe precision metal lathes and quick change tool posts can improve your metalworking skills. You might be surprised by how much you can create with them!

Lathe Precision Metal Lathe Quick Change Tool Post Guide

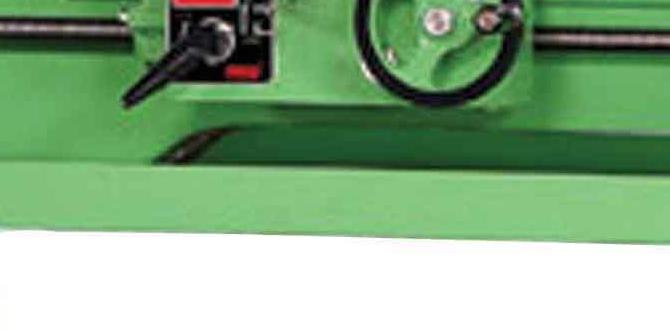

Lathe Precision Metal Lathe Quick Change Tool Post

Precision is key when using a lathe. A quick change tool post allows users to switch tools swiftly, saving time and effort. This feature enhances accuracy, making it easier to create intricate designs. Imagine working on a project and needing a different tool without losing focus. That’s the magic of a quick-change tool post! It’s not just efficient; it can boost creativity too! Learn how this small upgrade can make a big difference in your metalworking projects.Understanding Lathe Precision

Definition of precision in lathe machines. Importance of precision in metalworking applications.Precision in lathe machines means making parts just right—like baking a perfect cake without burning it! In metalworking, being precise is super important. It ensures parts fit together and work as they should. Imagine if a wheel on a car was made wrong. Yikes! That’s why a good lathe can be a lifesaver. A quick change tool post helps machinists switch tools fast, keeping things flowing smoothly!

| Aspect | Importance |

|---|---|

| Precision | Ensures proper fit and function. |

| Efficiency | Faster production and less waste. |

| Quality | Leads to better and lasting products. |

What is a Quick Change Tool Post?

Explanation of the quick change tool post mechanism. Benefits of using a quick change tool post over traditional tool holders.A quick change tool post is a nifty gadget on a lathe. It helps you swap tools quickly, so you can get back to work without a hitch. Imagine trying to bake a cake but needing to find a new whisk every time! With this tool post, changing tools is as easy as pie. The benefits? It saves time and keeps your projects moving forward. Plus, it’s like having a magic wand—one flick and you’re ready to tackle different tasks!

| Benefit | Quick Change Tool Post | Traditional Tool Holder |

|---|---|---|

| Time Efficiency | Fast tool swaps | Slow, tedious changes |

| Precision | Consistent setup | Variable alignment |

| User-Friendly | Easy to operate | Requires adjustments |

Key Features of Precision Metal Lathes

Essential components that define precision metal lathes. Importance of rigidity and accuracy in lathe performance.Precision metal lathes have key features that set them apart. First, they include rigid structures, which help in making accurate cuts. This helps keep everything steady while working. Second, high-quality bearings allow smooth movement for better precision. Finally, quick change tool posts give quick access to different tools. These elements ensure the lathe works well and produces exact shapes.

What are the important aspects of lathe performance?

Rigidity and accuracy are essential for lathe performance. They affect how well the lathe can cut materials. A stable lathe produces cleaner and more precise designs.

Did you know that even small errors can lead to larger issues in machining? That’s why choosing the right lathe matters!

Advantages of Using a Quick Change Tool Post

Timesaving benefits in tool changes during operations. Increased productivity and efficiency in machining processes.A quick change tool post can save you time during machining. Changing tools quickly helps you finish tasks faster. Instead of stopping to swap tools, you can keep working and achieve more. This means you will be more productive. Less wait time leads to higher efficiency. You can make more pieces in less time. Everyone loves completing tasks quickly, right?

Why Use a Quick Change Tool Post?

The quick change tool post helps speed up tool changes. It keeps your work rolling and enhances the overall workflow.Key Benefits:

- Less downtime

- More completed projects

- Better use of resources

Installation Guide for Quick Change Tool Posts

Stepbystep process for installing a quick change tool post. Tips for ensuring proper alignment and functionality.Installing a quick change tool post makes lathe work a breeze! Begin by removing the old tool holder. Clean up any grime like it’s a family clean-up day. Next, position the quick change tool post on the lathe’s slide. Make sure it’s straight—no one likes a wobbly tool! Use a wrench to tighten it securely. Double-check that it can slide back and forth easily. You want your tools to be like ice skaters—gliding smoothly!

For best results, align the tool post with the lathe center. If you mess this up, it’s like trying to dance with two left feet. To help, here’s a quick checklist:

| Step | Tip |

|---|---|

| Remove old tool | Clean the area well |

| Position tool post | Ensure it’s straight |

| Tighten bolts | Don’t overdo it! |

| Check movement | It should glide like a pro! |

With a bit of patience and these tips, you’ll have your quick change tool post installed in no time!

Choosing the Right Quick Change Tool Post for Your Lathe

Factors to consider when selecting a tool post type. Comparison of various brands and models available in the market.Choosing the right quick change tool post helps you work faster and better on your lathe. Consider these factors:

- Size and Compatibility: Make sure the tool post fits your lathe. Check the model and size options.

- Material: Look for strong materials that last longer, like steel or cast iron.

- Brand Reputation: Popular brands often provide reliable products. Some well-known names include Aloris and Phase II.

- Price: Compare prices to find a balance between quality and affordability.

When buying, read reviews and ask others for their thoughts. The right tool post helps you create amazing projects!

What should I consider when choosing a tool post?

Look for size, material, brand, and price.Which brands are best for quick change tool posts?

Aloris and Phase II are top choices.Maintenance Tips for Precision Metal Lathes and Tool Posts

Routine maintenance practices to prolong equipment life. Troubleshooting common issues with tool posts.Keeping your lathe and tool posts in tip-top shape is easier than you think! Regular checks, like cleaning and oiling, can keep your tools running smoothly. Think of it as giving them a spa day. If something goes wrong—like your tool post acting stubborn—check for tightness and make adjustments. Remember, a little TLC can turn a grumpy lathe into a happy one! Here are some tips:

| Maintenance Tips | Common Issues |

|---|---|

| Clean the lathe after use. | Tool post not securing? Check the screws! |

| Oil moving parts regularly. | Uneven cuts? Look for worn tools. |

| Inspect for any wear and tear. | Vibrations? Balance your workpiece! |

Keep up with these easy tasks, and your equipment will thank you—probably in smoother metal, not a thank-you note!

Real-World Applications of Precision Metal Lathes with Quick Change Tool Posts

Industries that benefit from precision machining. Case studies highlighting efficiency improvements.Many industries see great benefits from using precision machining. Manufacturing, aerospace, and automotive sectors are leading examples. These industries improve production times and reduce waste. For instance:

- Manufacturers cut production time by up to 30% by using quick change tool posts.

- Aerospace companies increased part accuracy and safety through advanced machining techniques.

- The automotive industry reduced costs and enhanced quality with better tooling systems.

These changes show how important precision metal lathes are for modern machinery.

Which industries benefit from precision machining?

Industries like manufacturing, aerospace, and automotive gain better efficiency and quality from precision machining.

Frequently Asked Questions (FAQs)

Common queries related to precision metal lathes and quick change tool posts. Answers to help users make informed decisions.Many people want to know how a precision metal lathe and its quick change tool post work. Here are some common questions and their answers:

What is a quick change tool post?

A quick change tool post lets users swap tools easily. This helps save time and makes work more efficient.

Why choose a precision metal lathe?

Precision lathes offer accuracy. They create detailed and exact shapes in metal.

Can I use any tool with a quick change post?

Not all tools fit every post. Check compatibility for the best results.

How does this improve my work?

A quick change tool post speeds up projects. It also reduces mistakes, making your work neater.

Conclusion

In summary, a lathe precision metal lathe with a quick change tool post makes machining easier and faster. You can quickly switch tools without losing accuracy. This feature saves time and boosts your productivity. If you’re interested, explore more about lathes and tool posts. With practice, you’ll master these tools and improve your skills in metalworking.FAQs

What Are The Advantages Of Using A Quick Change Tool Post On A Precision Metal Lathe Compared To Traditional Tool Holders?Using a quick change tool post on a precision metal lathe makes changing tools super fast and easy. You don’t waste time fiddling with screws. Instead, you simply click or slide the tools in and out. This helps you finish projects quicker. Plus, it makes your work more accurate because the tools stay in place better.

How Do You Properly Install And Align A Quick Change Tool Post On A Lathe For Optimal Performance?To install a quick change tool post on a lathe, first, turn off the machine. Then, remove the old tool holder and clean the area. Place the new tool post on the lathe’s tool holder. Tighten the screws firmly but not too tight. To align it, center the tool over the lathe’s center line. Adjust it until it fits snugly. Check and make sure it moves easily before you start working.

What Types Of Tooling Can Be Used With A Quick Change Tool Post On A Metal Lathe?You can use different tools with a quick change tool post on a metal lathe. Some common types are cutting tools, like drill bits, and turning tools. You can also use boring bars, which help make holes bigger. Tool holders are important, too, as they hold the tools in place. This makes it easy to switch tools quickly while you work.

What Maintenance Practices Should Be Followed To Ensure The Longevity And Accuracy Of A Quick Change Tool Post?To keep a quick change tool post working well, you should clean it often. Use a soft cloth to wipe off dirt and dust. Next, check the parts for wear or damage. You should also oil the moving parts to keep them running smoothly. Lastly, make sure all screws are tight and in place.

How Can A Quick Change Tool Post Improve Production Efficiency In A Machining Environment?A quick change tool post helps you switch tools faster on a machine. This means you wait less time between jobs. When you work quickly, you make more parts in a day. It also makes the work easier and keeps everyone happy!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Quick Change Tool Post On A Precision Metal Lathe Compared To Traditional Tool Holders? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a quick change tool post on a precision metal lathe makes changing tools super fast and easy. You don’t waste time fiddling with screws. Instead, you simply click or slide the tools in and out. This helps you finish projects quicker. Plus, it makes your work more accurate because the tools stay in place better.”}},{“@type”: “Question”,”name”: “How Do You Properly Install And Align A Quick Change Tool Post On A Lathe For Optimal Performance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a quick change tool post on a lathe, first, turn off the machine. Then, remove the old tool holder and clean the area. Place the new tool post on the lathe’s tool holder. Tighten the screws firmly but not too tight. To align it, center the tool over the lathe’s center line. Adjust it until it fits snugly. Check and make sure it moves easily before you start working.”}},{“@type”: “Question”,”name”: “What Types Of Tooling Can Be Used With A Quick Change Tool Post On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use different tools with a quick change tool post on a metal lathe. Some common types are cutting tools, like drill bits, and turning tools. You can also use boring bars, which help make holes bigger. Tool holders are important, too, as they hold the tools in place. This makes it easy to switch tools quickly while you work.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed To Ensure The Longevity And Accuracy Of A Quick Change Tool Post? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a quick change tool post working well, you should clean it often. Use a soft cloth to wipe off dirt and dust. Next, check the parts for wear or damage. You should also oil the moving parts to keep them running smoothly. Lastly, make sure all screws are tight and in place.”}},{“@type”: “Question”,”name”: “How Can A Quick Change Tool Post Improve Production Efficiency In A Machining Environment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A quick change tool post helps you switch tools faster on a machine. This means you wait less time between jobs. When you work quickly, you make more parts in a day. It also makes the work easier and keeps everyone happy!”}}]}