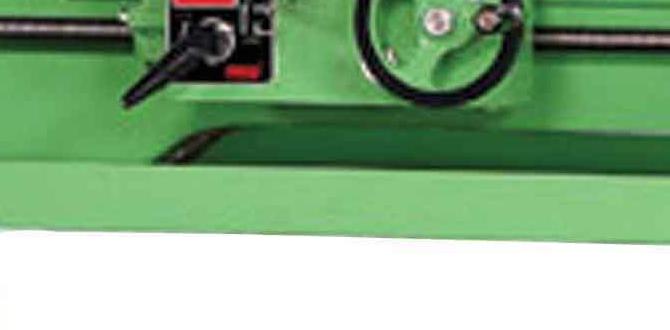

Have you ever wondered how machines create perfect shapes from metal? A lathe is the tool that makes this magic happen. It spins metal while cutting it into precise shapes. But what makes a lathe truly special? It’s all about precision and torque.

Imagine a sculptor chiseling away at a block of stone. They need to balance power and control. This is similar to what a lathe does. The right torque helps the lathe cut smoothly without damaging the metal. Curious how it works?

Here’s a fun fact: the word “lathe” comes from an old term that means “to twist.” This twisting motion is what allows a lathe to create straight lines and perfect circles. It’s what gives the final product its sleek look.

In this article, we’ll dive into the world of lathe precision, metal lathes, and torque. You might discover just how important these elements are in making amazing metal creations. Ready to learn more?

Lathe Precision Metal Lathe Torque: Understanding Its Importance

Understanding Lathe Precision and Metal Lathe Torque

Need to shape metal accurately? A precision metal lathe can help. It spins metal pieces, allowing you to cut, sand, or drill with exactness. Torque plays a key role here. High torque means the lathe can handle tough materials without slowing down. Imagine creating parts for your cool robot! Precision ensures that every piece fits perfectly. Don’t overlook how important a good lathe is for any metalworking project.Understanding Precision in Lathe Operations

Definition and importance of precision in machining.. Factors affecting precision in lathe work..Precision in machining is key! It means making parts exactly right. If it’s off, tools can misbehave. Think of a lathe: it spins metal to shape it neatly. Importance? A precise piece fits perfectly, which saves time and materials.

However, precision doesn’t just appear. It relies on several factors. For example:

| Factor | Description |

|---|---|

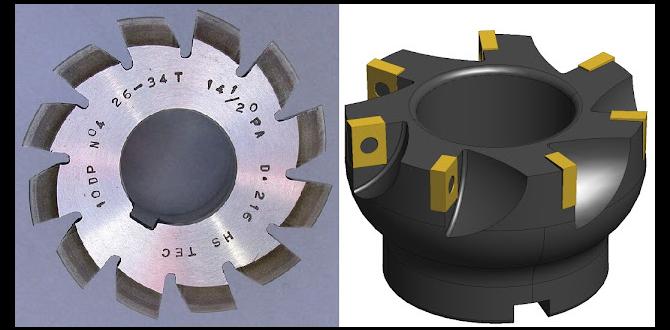

| Tool Quality | Good tools can shave away tiny bits of metal without complaints! |

| Speed | Too fast? Parts might dance instead of settle. |

| Operator Skill | An experienced hand can make wonders happen! |

Keep these points in mind to create masterpieces on your lathe. Remember, a little twist can make a big difference!

The Role of Torque in Metal Lathe Performance

Explanation of torque and its significance in lathe operations.. How torque influences cutting efficiency and finish quality..Torque is the force that helps a lathe spin its tools and workpieces. It is essential for smooth operation. With the right torque, a lathe cuts materials efficiently. This leads to better finish quality and shapes. Low torque can cause poor cuts and rough edges. High torque allows for deeper cuts and faster work. This results in improved precision and faster production.

Why does torque matter in lathe work?

Torque affects how well a lathe cuts materials. More torque means better cutting efficiency and smoother finishes. Low torque can result in errors, while high torque helps maintain quality.

- High torque improves cutting speed.

- Better torque leads to finer finishes.

- Low torque can lead to workpiece damage.

Calculating Required Torque for Metal Lathe Work

Formulas and methods for torque calculation.. Example scenarios for different materials and operations..To find the right torque for a metal lathe, you can use simple formulas. One popular formula is: Torque (T) = Force (F) × Distance (D). You multiply the force applied to the workpiece by the distance from the center of rotation. Different materials need different torques. For example:

- Wood: Lower torque needed, around 5-10 Nm.

- Aluminum: Medium torque required, about 15-25 Nm.

- Steel: Higher torque, ranging from 30-50 Nm.

Always choose the right torque to get the best results while working on your projects.

How do you calculate torque for different materials?

Use the formula: Torque = Force x Distance. Adjust it based on the material’s hardness.

Enhancing Lathe Precision Through Proper Torque Settings

Recommended torque settings for various metal lathe operations.. Techniques for adjusting and maintaining optimal torque..Getting the right torque on your lathe is like finding the perfect pizza topping: it can make or break your project! For metal lathe work, different operations need different torque settings. You can refer to the table below for some recommended torque values to kick things off:

| Operation | Recommended Torque (ft-lbs) |

|---|---|

| Turning | 5-15 |

| Facing | 4-10 |

| Drilling | 10-20 |

Adjusting torque is key. Always check for tightness like you check your shoelaces! Regular maintenance and recalibration can ensure your lathe keeps running smoothly. Remember, too much torque is like overcooking spaghetti—nobody wants that mess!

Common Challenges with Torque and Precision in Lathe Work

Typical issues faced when precision and torque are misaligned.. Tips for troubleshooting and resolving torquerelated problems..Problems with torque and precision in lathe work can be frustrating. Misalignment can lead to poor cuts and wasted materials. You might face issues like uneven surfaces or incorrect dimensions. Here are some simple tips to troubleshoot:

- Check the tool speed and make sure it matches the material.

- Inspect tool wear regularly to ensure sharpness.

- Test the lathe settings for accurate torque.

- Use a dial gauge to measure both precision and alignment.

Addressing these challenges can lead to smoother operations and better finished products.

What are typical issues wrong with torque and precision?

Common issues include inaccurate dimensions and rough surfaces. Misaligned torque often results in these problems, making it hard to achieve desired outcomes.

Case Studies: Success Stories in Precision Lathe Work

Realworld examples of achieving high precision through effective torque management.. Lessons learned and applications for different industries..In real-world projects, managing torque has turned ordinary lathe work into something extraordinary. For instance, a small auto parts company improved their precision by 25% just by tweaking their torque settings. Imagine going from “Oops!” to “Perfect!” as parts fit like a glove. Industries like aerospace and manufacturing learned that the right torque is key to success. It’s like ordering pizza: you need the right toppings for a delicious slice! Here are some lessons learned:

| Industry | Lesson Learned |

|---|---|

| Aerospace | Small adjustments equal high safety. |

| Automotive | Precision parts save costs. |

| Electronics | Proper torque avoids malfunctions. |

So, whether you’re building rockets or toasters, remember that the right torque management makes all the difference!

Future Trends in Lathe Technology and Precision Machining

Innovations in lathe design focusing on precision and torque control.. Predictions for the evolution of metal lathe technology..The future of lathe technology looks bright. Innovations are on the way to enhance precision and torque control. New designs make lathes more accurate than ever. These machines will use smarter systems to adjust torque, ensuring better results. Also, many predict metal lathes will become more user-friendly. Imagine lathes that talk to you, guiding each step of the process! This could make metalworking easier for everyone.

What are the new trends in lathe technology?

Future trends include smarter designs, better torque control, and user-friendly interfaces. These changes will help machines work more efficiently and accurately.

Possible Innovations:

- Smart torque sensors

- Advanced materials for longer life

- User-friendly digital interfaces

Conclusion

In conclusion, understanding lathe precision, metal lathe torque, and their importance helps you in machining projects. Precision ensures accuracy in your work, while torque affects how well a lathe operates. To improve your skills, practice using a metal lathe and explore tutorials online. With time, you’ll master these concepts and create amazing projects! Keep learning and experimenting!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Precision, Metal Lathe, And Torque:Sure! Here are five related questions on lathe precision, metal lathes, and torque: 1. How does a lathe work? A lathe is a machine that spins metal or wood to shape it. We put a piece on it, and it turns while we use tools to cut or smooth the surface. 2. What is metal lathe precision? Metal lathe precision means how accurately the lathe can shape the metal. We want it to be very exact so that everything fits perfectly. 3. Why is torque important for a lathe? Torque is the strength that helps the lathe turn the metal. We need enough torque to shape tough materials without breaking anything. 4. How can we make a lathe more precise? We can check and adjust the tools and settings often. Keeping everything clean and sharp helps us make better parts. 5. What do you use a lathe for? We use lathes to make parts for machines, toys, or even furniture. They help us create all sorts of cool things!

Sure! Please give me the question you want me to answer.

What Factors Influence The Torque Output Of A Metal Lathe During Precision Machining Operations?The torque output of a metal lathe depends on a few important things. First, the power of the motor affects how much force it can use. Next, the cutting tool’s shape and sharpness matter – sharper tools need less force. Also, the speed at which you turn the lathe changes how much torque is needed. Finally, the material you are cutting can make the lathe work harder or easier.

How Does The Rigidity Of A Lathe Affect Its Precision And Torque Capabilities?The rigidity of a lathe is how strong and steady it is when we use it. A strong lathe can hold tools tightly, making cuts very precise. If the lathe is wobbly, the cuts may not be right. This means we can use more force, or torque, without losing control. So, a rigid lathe helps us work better and makes sure our projects turn out well.

What Is The Role Of Spindle Speed In Maintaining Optimal Torque For Precision Machining On A Lathe?Spindle speed is how fast the lathe turns the piece you are shaping. If the speed is too high, it can make cutting harder and less smooth. When we find the right speed, we help the machine work better and use energy wisely. This makes it easier to cut and shape materials just the way we want. So, the right spindle speed is important for good results!

How Can Operators Calibrate And Adjust Torque Settings To Achieve Better Accuracy On A Precision Metal Lathe?To get better accuracy on a metal lathe, you can adjust the torque settings. First, check the machine’s manual for the right numbers. Then, use a torque wrench to carefully tighten the parts. If something feels loose, you should tighten it a bit more. Always make sure everything is set correctly before starting your work.

What Are The Common Signs Of Inadequate Torque In Lathe Operations, And How Can They Impact The Overall Precision Of Machined Parts?If the turning tool on a lathe isn’t tight enough, you might see rough edges on the parts. The machine could also make strange sounds. You might notice that parts don’t fit together well. This means the parts won’t be precise or exact, which can cause problems later.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Precision, Metal Lathe, And Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions on lathe precision, metal lathes, and torque: 1. How does a lathe work? A lathe is a machine that spins metal or wood to shape it. We put a piece on it, and it turns while we use tools to cut or smooth the surface. 2. What is metal lathe precision? Metal lathe precision means how accurately the lathe can shape the metal. We want it to be very exact so that everything fits perfectly. 3. Why is torque important for a lathe? Torque is the strength that helps the lathe turn the metal. We need enough torque to shape tough materials without breaking anything. 4. How can we make a lathe more precise? We can check and adjust the tools and settings often. Keeping everything clean and sharp helps us make better parts. 5. What do you use a lathe for? We use lathes to make parts for machines, toys, or even furniture. They help us create all sorts of cool things!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Torque Output Of A Metal Lathe During Precision Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The torque output of a metal lathe depends on a few important things. First, the power of the motor affects how much force it can use. Next, the cutting tool’s shape and sharpness matter – sharper tools need less force. Also, the speed at which you turn the lathe changes how much torque is needed. Finally, the material you are cutting can make the lathe work harder or easier.”}},{“@type”: “Question”,”name”: “How Does The Rigidity Of A Lathe Affect Its Precision And Torque Capabilities?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The rigidity of a lathe is how strong and steady it is when we use it. A strong lathe can hold tools tightly, making cuts very precise. If the lathe is wobbly, the cuts may not be right. This means we can use more force, or torque, without losing control. So, a rigid lathe helps us work better and makes sure our projects turn out well.”}},{“@type”: “Question”,”name”: “What Is The Role Of Spindle Speed In Maintaining Optimal Torque For Precision Machining On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Spindle speed is how fast the lathe turns the piece you are shaping. If the speed is too high, it can make cutting harder and less smooth. When we find the right speed, we help the machine work better and use energy wisely. This makes it easier to cut and shape materials just the way we want. So, the right spindle speed is important for good results!”}},{“@type”: “Question”,”name”: “How Can Operators Calibrate And Adjust Torque Settings To Achieve Better Accuracy On A Precision Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To get better accuracy on a metal lathe, you can adjust the torque settings. First, check the machine’s manual for the right numbers. Then, use a torque wrench to carefully tighten the parts. If something feels loose, you should tighten it a bit more. Always make sure everything is set correctly before starting your work.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Inadequate Torque In Lathe Operations, And How Can They Impact The Overall Precision Of Machined Parts?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the turning tool on a lathe isn’t tight enough, you might see rough edges on the parts. The machine could also make strange sounds. You might notice that parts don’t fit together well. This means the parts won’t be precise or exact, which can cause problems later.”}}]}