Have you ever wondered how to make your lathe work better? Many people face problems with tool changes during their projects. This is where lathe quick change tool post shims come in handy. They help adjust the height of your tools easily, saving time and effort.

Imagine a busy workshop. You’re deep into a project, and the tool height doesn’t feel right. You spend precious minutes fiddling with your setup. Wouldn’t it be nice to have a simple solution to fix that?

Fun fact: The right shims can make a huge difference. They can help you achieve perfect cuts and smooth finishes. With the right setup, you’ll create pieces that look professional and polished. That’s what every maker dreams of!

In this article, we’ll explore how lathe quick change tool post shims work. You’ll discover their benefits and how you can use them effectively. Let’s dive into the world of shimming and see how it can enhance your lathe experience!

Lathe Quick Change Tool Post Shims: A Comprehensive Guide

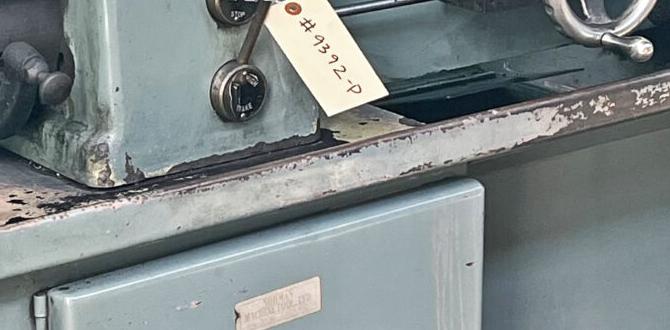

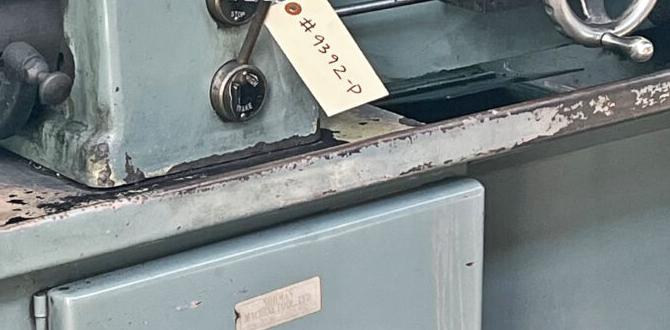

Lathe Quick Change Tool Post Shims

Lathe quick change tool post shims are essential for precise machining. They help adjust the height of the tool post, ensuring smooth cutting operations. Without shims, tools might not align properly, causing poor cuts. Imagine trying to slice a cake without a steady hand—it just won’t work! Proper shimming can boost your lathe’s performance and make your projects easier. Did you know that small adjustments can lead to big improvements in your work? Explore these handy tools and enhance your machining skills!Understanding Lathe Quick Change Tool Posts

Definition and purpose of quick change tool posts. Benefits of using quick change tool systems in machining.Quick change tool posts are the superheroes of machining! They help workers swap tools quickly, saving time on projects. Imagine a magic wand that lets you change your tool in seconds. This speed boosts productivity and lets you focus on crafting perfect parts. Using a quick change system means less fuss and more fun in the workshop. Plus, who wants to waste time searching for the right tool? With these nifty gadgets, every second counts!

| Benefits of Quick Change Tool Posts |

|---|

| Faster tool changes |

| Increased efficiency |

| Less downtime |

| Improved precision |

What are Tool Post Shims?

Explanation of tool post shims and their functions. Importance of precise shimming in tool setup.Shims might sound like a dance move, but they do something very important! They help keep tool posts level on a lathe. This is key because it makes sure that your tools are just right, not too high or too low. If they’re wobbly, your work can look like a toddler’s art project. Precise shimming means your cuts are accurate, helping you make smooth parts. No one wants a lopsided finish, right?

| Function of Shims | Importance |

|---|---|

| Level tool post | Ensures accurate cuts |

| Adjust height | Prevents wobbling |

| Enhance precision | Improves product quality |

How to Choose the Right Shim for Your Lathe

Factors to consider when selecting shims (material, thickness, design). Compatibility with different lathe models and tool posts.Choosing the right shim for your lathe is important. Think about these three factors:

- Material: Different materials suit different needs. Metal shims are strong, while plastic ones are lightweight.

- Thickness: The thickness affects height and stability. Measure carefully to get the right fit.

- Design: Ensure the design matches your tool post for proper function.

Compatibility is key too. Check your lathe model and tool post type. This helps avoid problems and ensures smooth operation.

What should I consider when selecting lathe shims?

Consider material, thickness, and design. These affect performance and how well shims fit equipment. Always match shims with your specific lathe model. This guarantees the best results!

Steps to Install Tool Post Shims Effectively

Detailed installation process, including required tools. Common pitfalls to avoid during installation.Installing tool post shims can be easy if you follow some steps. First, gather your tools: a wrench, screwdriver, and calipers. Clean the area where the shim will go. Position the shim carefully under the tool post. Tighten the screws securely, but don’t overdo it. Avoid common mistakes, like misaligning or using the wrong size shim. Check your work by using the calipers to ensure everything is straight.

What tools do I need for installation?

You will need a wrench, screwdriver, and calipers. These tools help you adjust and measure the tool post effectively.

Tips for a smooth installation:

- Make sure the area is clean.

- Double-check shim size before installation.

- Align everything properly to avoid issues.

Maintaining Your Quick Change Tool Post System

Routine maintenance tips for tool posts and shims. Signs that indicate the need for replacement or adjustments.To keep your tool post in top shape, regular care is key. Check for loose parts or wear signs. Clean shims and surfaces often. Use oil to keep moving parts smooth. Look for issues like:

- Rust or dents on the tool post.

- Difficulty in changing tools.

- Uneven cuts on your projects.

By keeping an eye on these points, you’ll know when to replace or adjust parts. Regular maintenance can make your work easier and more enjoyable!

How can I tell when to replace tool post parts?

Look for rust, cracks, or difficulty in using your tool post. If your projects aren’t cutting properly, it might be time for a check-up.

Advanced Techniques for Shim Adjustment

Techniques for finetuning tool heights and angles using shims. Case studies showing effective shim adjustments in various machining scenarios.Fine-tuning tool heights and angles is important for excellent machining. Using shims effectively can help achieve this. For example, by adding shims, a tool can be raised or tilted precisely. Adjustments should be made based on the specific task. Here are some popular techniques:

- Begin with a level surface.

- Use thin and thick shims for precise adjustments.

- Test cuts before finalizing adjustments.

Many machinists have reported better results with these methods. For instance, one user improved their cuts by 30% just by adjusting tool height. Remember, small changes can make a big difference!

What are the benefits of using shims for adjustments?

The benefits of using shims include better accuracy, improved tool performance, and longer tool life.

FAQs about Lathe Quick Change Tool Post Shims

Common questions and answers related to shims and tool post systems. Troubleshooting common issues encountered with shims.Got questions about shims and tool post systems? You’re not alone! Many folks wonder, “What do shims do?” Well, shims help adjust the height of your tool post for better accuracy. Some might ask, “Why does my tool post wiggle?” This often happens because shims aren’t snug enough. Just think of shims as your tool post’s best buddy. They keep it steady and happy! Need more help? Check out the table below for quick answers to frequent shim concerns:

| Question | Answer |

|---|---|

| What does a shim do? | It adjusts the height of your tool post. |

| Why is my tool post loose? | Shims may not be properly secured. |

| How many shims do I need? | Usually, one or two should do the trick! |

Resources for Further Learning

Recommended books, articles, and online resources on lathe tools and shims. Links to forums and communities for tool post enthusiasts.If you want to dive deeper into the world of lathe tools and those nifty quick change tool post shims, you’re in luck! There are plenty of resources available. Check out some highly recommended books that make these topics fun and easy. You can find articles that explain everything from basics to advanced tricks, ensuring you don’t accidentally make a paperweight instead of a part.

| Resource Type | Title/Link |

|---|---|

| Books | The Art of Lathe Work |

| Articles | Understanding Tool Post Shims |

| Forums | Lathe Lovers Forum |

For community support, don’t miss the forums where tool post enthusiasts gather. They share tips, tricks, and maybe even some funny mishaps. Remember, knowledge is power, and laughter is the best tool—unless you’re using a lathe, of course!

Conclusion

In summary, lathe quick change tool post shims help improve accuracy and speed when using lathes. They ensure tools sit tight and steady, which leads to better work. For best results, you should check shim thickness and adjust as needed. We encourage you to explore more about shims online or even try making your own for practice!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Quick Change Tool Post Shims:Lathe quick change tool post shims are small pieces used in lathes. They help hold the cutting tools more securely. You can adjust these shims to get the right tool height. This makes your work more accurate. Shims help you change tools quickly and easily when you’re working.

Sure! Please provide the question you want me to answer.

What Are Lathe Quick Change Tool Post Shims, And What Purpose Do They Serve In Machining Operations?Lathe quick change tool post shims are small pieces of material. We use them to adjust the height of tools on a lathe machine. This helps keep the tool at the right level while cutting. If the tool is not level, it can make bad cuts. So, shims help us get better and more accurate results when we work.

How Do You Determine The Appropriate Thickness Of Shims Needed For A Quick Change Tool Post Setup On A Lathe?To find the right thickness of shims for a quick change tool post on a lathe, you start by checking the height of the tool holder. You want the tool to sit at the right level with the lathe’s center. Use a ruler or caliper to measure the difference. Then, choose shims that fill that gap. You may need to try different thicknesses until it fits just right.

What Materials Are Commonly Used For Making Shims For Lathe Tool Posts, And How Do They Affect Tool Performance?We commonly use metal, plastic, or wood to make shims for lathe tool posts. Metal shims are strong and last a long time. Plastic shims are lighter and easier to cut. Wood shims can be used, but they wear out faster. These shims help keep your tools at the right angle, making them cut better.

Can Improper Shim Placement Or Insufficient Shimming Lead To Tool Misalignment, And What Are The Potential Consequences Of This?Yes, if you place shims incorrectly or don’t use enough, tools can become misaligned. This means they won’t work properly. When tools are not aligned well, they can break or damage materials. You might also make mistakes in your projects. It’s important to shim correctly for better results!

What Are Some Tips For Safely Installing And Adjusting Shims In A Quick Change Tool Post System On A Lathe?To install shims safely, first, turn off the lathe. Then, wear safety glasses to protect your eyes. Make sure your hands are clean and dry when handling shims. Use a small tool to adjust them gently. Always double-check that everything is tight before you start the machine again.