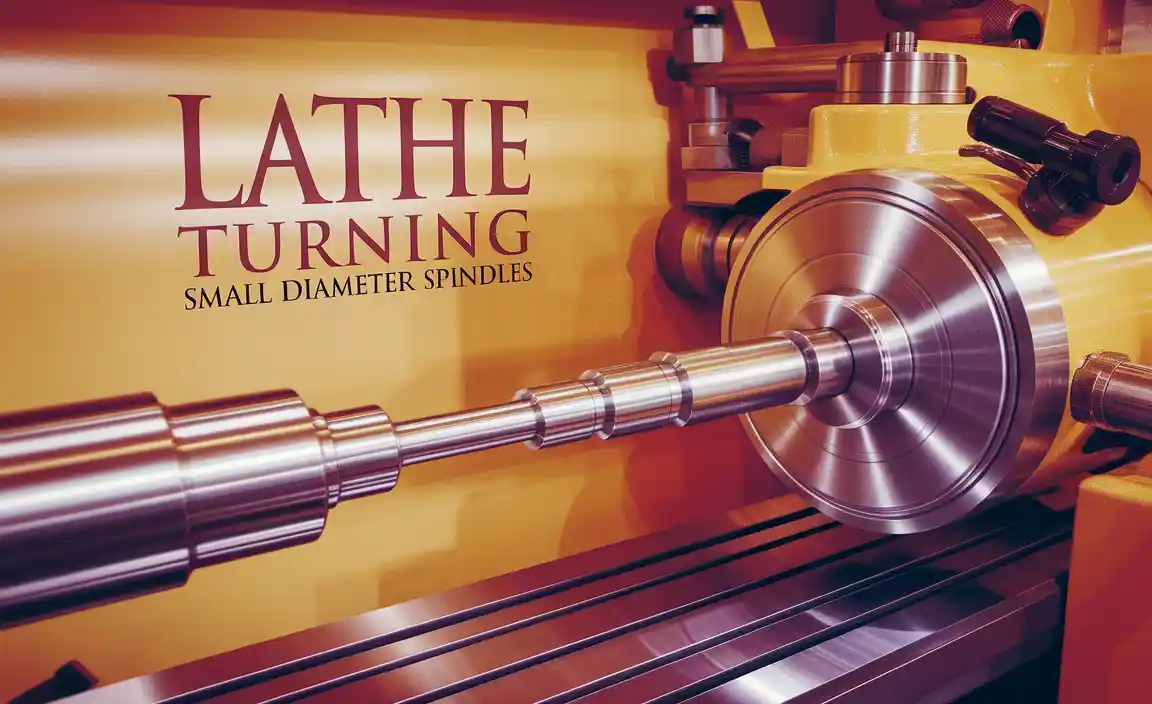

Have you ever seen a lathe in action? It’s an amazing tool that spins materials to create shapes. But sometimes, users face challenges with lathe quill travel. This can lead to frustration and mistakes. Imagine trying to carve a beautiful piece of wood, but something just doesn’t feel right. That’s often because of issues with the quill.

Lathe quill travel issues can confuse beginners and experts alike. Picture this: you’re almost finished with a project, and suddenly, the quill won’t move as expected. It can feel like hitting a brick wall. With the right knowledge, you can solve these problems quickly. Let’s dive into why these issues happen and how to fix them!

Lathe Quill Travel Issues: Understanding Common Problems

Lathe Quill Travel Issues

Lathe quill travel issues can slow down your projects. Imagine trying to hollow a piece of wood, but the quill won’t move smoothly. This can lead to frustrating mistakes. These problems often arise from dirt buildup or lack of lubrication. Regular maintenance can help keep your lathe in top shape. Did you know that a clean quill can improve your work’s precision? Fixing quill travel issues makes your work easier and more enjoyable.Common Quill Travel Issues

Description of various travel issues affecting the lathe quill.. Symptoms that indicate problems with quill travel..Quill travel issues can cause big problems in your lathe. These issues may show up as strange noises or uneven cuts. You might notice that the quill doesn’t move smoothly. Here are some common signs of trouble:

- Sticking when advancing or retracting

- Unusual noises during operation

- Inconsistent depth of cuts

- Play or wobble in the quill

Identifying these symptoms early can save time and money. Always pay close attention to how your lathe feels during use.

What are common quill travel issues?

Common issues include sticking, noise, and inconsistent cuts. These problems often mean your quill needs maintenance or part replacement. Regular checks help ensure everything runs smoothly.

Signs of quill travel issues:

- Sticking action

- Rattling sounds

- Uneven surfaces on workpieces

Diagnosing Quill Travel Problems

Stepbystep guide to identifying specific issues with the quill.. Tools and techniques for effective diagnosis..Is your lathe quill feeling a bit sluggish? Let’s tackle those travel troubles! First, check for any visible blockages by inspecting the quill area. Use a flashlight and a sense of wonder—it’s amazing what you can find! Next, employ a ruler or caliper to measure the quill travel accurately. Sometimes, you might need a little bit of lubrication, like oil for your squeaky bicycle—just make sure not to overdo it!

| Tools | Techniques |

|---|---|

| Flashlight | Inspect for blockages |

| Ruler/Caliper | Measure travel distance |

| Lubricant | Apply as needed |

Causes of Quill Travel Issues

Analysis of mechanical causes such as wear and tear or misalignment.. Influence of environmental factors like temperature or humidity on quill performance..Quill travel problems can happen for many reasons. One key cause is wear and tear over time. Parts can get old and not work as well. Another is misalignment, where pieces don’t fit together correctly. Environmental factors also play a role. Changes in temperature and humidity can affect how the quill moves. For example:

- High humidity might cause rust.

- Temperature changes can expand or shrink materials.

Understanding these causes helps in keeping the quill in good shape.

What causes quill travel issues?

Causes include wear, misalignment, and environmental factors like temperature and humidity. These issues can lead to poor performance, affecting the overall operation of the lathe. Proper maintenance is crucial for smooth functioning.

Repairing Quill Travel Issues

Detailed procedures for fixing common quill problems.. Information on replacement parts and upgrades for better performance..Fixing quill travel issues can sound tough, but it’s like solving a puzzle! First, check for dirt or dust that can cause the quill to stick. A simple cleaning can do wonders. If the problem keeps happening, it might be time for a replacement part. You could upgrade to a better quill for smooth sailing. Here’s a handy table to help you sort it all out:

| Problem | Solution | Replacement Parts |

|---|---|---|

| Sticking Quill | Clean thoroughly or lubricate | Lubricant, brushes |

| Worn-out Quill | Replace with a new one | Upgraded quills |

By taking the time to fix these issues, your lathe can work like magic! Remember, a well-maintained quill can help you get the job done quicker than a squirrel on caffeine!

Preventive Maintenance for Quill Longevity

Best practices for regular maintenance to prevent quill travel issues.. Recommended schedules for inspection and lubrication..Keeping your lathe quill in good shape is important for smooth operation. Regular maintenance can help prevent quill travel issues, saving you time and money. Here are some best practices:

- Check the quill for wear and tear monthly.

- Lubricate moving parts every two weeks.

- Clean dust and debris after each use.

- Inspect for rust or damage before long breaks.

By following these steps, your quill will last longer and run better.

How often should I inspect my lathe quill?

You should inspect your lathe quill at least once a month. Regular checks help catch problems early, ensuring smooth and safe operation.

When to Seek Professional Help

Indicators that suggest it’s time to consult a technician or specialist.. Potential costs and considerations involved in professional repairs..Watch for signs that it’s time to call an expert. If the lathe quill isn’t moving smoothly, or you hear strange noises, these are red flags. Problems can worsen and might cost more later. Consider the following:

- Visible damage on the quill

- Difficulty adjusting the settings

- Frequent breakdowns

Repair costs vary. It helps to get a few quotes. A professional can prevent bigger issues and save overall money.

When should I consult a technician?

If your lathe quill has problems, it’s best to consult a technician right away. **Ignoring issues can lead to costly repairs later.**

Conclusion

In summary, lathe quill travel issues can be frustrating but are manageable. Always check your machine’s settings and alignment. Regular maintenance helps prevent problems. If you face trouble, consult the user manual or seek expert advice. We can improve our skills by learning more about these topics. Take steps today to keep your lathe in top shape!FAQs

Certainly! Here Are Five Related Questions Regarding Lathe Quill Travel Issues:Sure! If you have problems with the lathe quill travel, you might ask why it won’t move. Another question is how to check if it’s stuck. You might wonder what causes it to get stuck, too. You could also ask if it’s safe to use the lathe like that. Finally, you may want to know how to fix the quill travel problem.

Sure! Please provide the question you would like me to answer.

What Are The Common Symptoms Of Insufficient Quill Travel On A Lathe?If the quill on a lathe doesn’t move enough, you might notice some problems. The tool may not cut correctly, leaving rough edges on your work. You might see uneven shapes, making it hard to get a perfect finish. Plus, you could have trouble changing the sizes of the pieces you’re working on. These signs mean you need to adjust the quill.

How Can Misalignment Of The Quill Affect Machining Accuracy And Surface Finish?If the quill, which holds the cutting tool, is not lined up right, it can cause problems. You might get uneven cuts, which makes your work less accurate. This can also leave rough surfaces instead of smooth ones. In short, a misaligned quill makes it hard to create good, clean shapes. We always want our tools to be straight for the best results!

What Maintenance Practices Can Prevent Quill Travel Issues On A Lathe?To keep a lathe working well, we should check the quill often. First, we can clean it to remove dust and dirt. Next, we need to oil the moving parts to help them slide smoothly. Also, we should check for any loose screws or parts and fix them. This way, we can avoid problems while using the lathe.

How Do You Troubleshoot And Diagnose Problems With The Quill’S Movement Or Travel Range?To fix problems with the quill’s movement, start by checking if it’s clean. Dust or dirt can cause sticking. Next, check for any loose parts; tight screws help things move smoothly. If it still doesn’t work, try looking at the motor or controller. They need to be in good shape to help the quill move properly.

What Modifications Or Upgrades Can Be Made To Enhance Quill Travel Capabilities On Older Lathe Models?To make older lathes work better, you can upgrade a few things. First, adding a longer quill can help it move farther. Second, you might want to change to a better motor for more power. Lastly, you can put in a smooth guide like ball bearings for easier movement. These changes will help your lathe cut more easily.