Have you ever wondered how metal lathes work? These machines are fascinating tools for shaping metal. But what happens when they break down or wear out? That’s where lathe rebuilding comes in. Rebuilding your lathe can breathe new life into it. Imagine taking an old, rusty machine and turning it into a shining example of precision.

Many hobbyists and professionals alike choose to rebuild their metal lathes. It’s not just about repairing; it’s about making something better. Building a sturdy lathe bench also plays a big part in this process. A well-built bench can support heavy tools and keep your workspace organized.

With some effort and knowledge, you can transform your old lathe into a reliable machine again. So, why not dive into the world of lathe rebuilding? You’ll find it rewarding and exciting. Let’s explore the steps to make your metal lathe work like new, and learn how a proper bench can change everything!

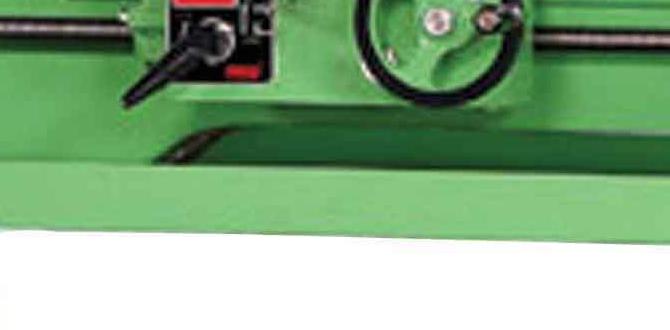

Lathe Rebuilding: Transforming Your Metal Lathe Bench

Lathe Rebuilding Metal Lathe Bench

Have you ever wondered how to restore a worn-out metal lathe? Rebuilding a lathe can breathe new life into your workshop. You can start by assessing parts like the bed, tailstock, and carriage. A sturdy bench is key; it supports your lathe while you work. Did you know that a solid foundation can improve your machine’s accuracy? Join the growing number of hobbyists who find satisfaction in reviving these machines and enhance your metalworking skills!Understanding Metal Lathe Rebuilding

Definition of lathe rebuilding. Importance of maintaining and rebuilding metal lathes.Lathe rebuilding means fixing and updating a metal lathe so it works like new. Think of it as giving your favorite toy a makeover! Keeping lathes in shape is super important. A well-maintained lathe can last much longer, saving you money and time. Plus, it makes your workshop safer and more fun, like having a shiny new toy every day! So, let’s keep those machines purring like kittens!

| Benefits of Rebuilding | Why It Matters |

|---|---|

| Increased Lifespan | Save money by avoiding replacements. |

| Better Performance | Get precise cuts and smoother operation. |

| Safety | Reduce the risk of accidents in the shop. |

Common Issues in Metal Lathes

Signs that indicate a need for rebuilding. Identifying parts that commonly wear out.Metal lathes can show signs that they need a rebuild. Look for uneven cuts or strange sounds while working. Worn-out parts often include bearings, belts, and gears. These pieces experience wear over time. Catching these issues early can save you money and time. Regular checks are important to keep your lathe in good shape.

What are common signs that a lathe needs rebuilding?

Signs of needing a rebuild include:

- Uneven cuts in materials.

- Unusual noises during operation.

- Vibrations or shaking while running.

- Difficulty adjusting speeds or settings.

Remember, noticing these signs early helps keep your projects on track!

Preparing for a Lathe Rebuild

Tools and materials required. Safety precautions to consider before starting.Before you dive into rebuilding that lathe, gather your tools and materials. You’ll need items like screwdrivers, wrenches, and maybe a snack (because rebuilding can take a while!). Don’t forget your trusty safety gear! Protect your eyes and hands, or you might end up looking like a confused raccoon with grease marks everywhere. Safety first, right?

| Tools | Materials | Safety Gear |

|---|---|---|

| Screwdrivers | Grease | Safety goggles |

| Wrenches | O-rings | Gloves |

| Hammers | Replacement parts | Dust mask |

Remember to follow safety tips like keeping your workspace tidy and not wearing loose clothing. Trust me, no one wants to get caught in a lathe! You’ll be amazed at how much smoother your project goes with everything in order.

Disassembling the Metal Lathe

Stepbystep process for disassembly. Tips for labeling and organizing parts.First, gather your tools. You will need a wrench, screwdriver, and a pair of pliers. Then, follow these steps to disassemble your lathe:

- Remove the tailstock first.

- Next, take off the carriage.

- Lastly, detach the bed from the base.

Label each part as you go. Use tape or small bags to keep them organized. This makes rebuilding easy and fun!

What are the best tips for organizing parts?

Label everything clearly. Group similar parts together. Consider using a notebook to track where each piece belongs. This will save you time later.

Inspecting and Cleaning Components

Techniques for thorough inspection of key parts. Effective cleaning methods to ensure optimal function.Checking your lathe parts is very important. Use these simple techniques for a thorough inspection:

- Look for wear or damage on all components.

- Use a magnifying glass to find tiny cracks.

- Check alignment with a straight edge.

Cleaning is just as crucial. Here are some effective methods:

- Wipe surfaces with a soft cloth soaked in oil.

- Use a brush to remove dust and debris.

- Apply a cleaner safe for metals to stubborn spots.

Keep your lathe in top shape by regularly inspecting and cleaning its parts!

How often should I inspect and clean my lathe?

Inspect and clean your lathe every month. This helps catch problems early and keeps it running smoothly.

Repairing and Replacing Parts

Criteria for deciding when to repair or replace components. Sources and options for replacement parts.Choosing whether to fix or replace parts of your lathe is important. First, consider how damaged the part is. If it costs too much to repair, it might be better to replace it. Next, look for replacement options. Many shops and online stores sell parts for lathes. You can often find used parts that work well. Also, check if there are better models available.

What should you consider when repairing or replacing lathe parts?

Look at cost, condition, and availability of parts. A small crack might be fixed easily, while a damaged motor may need a new one.

Some tips for making a decision:

- Repair costs versus new part costs.

- How critical is the part to your lathe’s function?

- Can you find a better alternative?

Reassembly of the Metal Lathe

Guidelines for reassembling the lathe correctly. Common pitfalls to avoid during reassembly.Reassembling your metal lathe is an exciting step, but it requires careful attention. Follow these guidelines for success:

- Keep all parts organized. This helps you find what you need.

- Use the manuals. They show the correct order for putting things back.

- Check for wear and tear. Replace old parts before reassembly.

Be aware of common pitfalls:

- Forgetting to clean parts can lead to poor performance.

- Over-tightening screws might damage the lathe.

- Ignoring alignment can cause issues later on.

Taking your time will help you avoid mistakes. Make the process enjoyable!

What are the best practices for reassembling a metal lathe?

Best practices include keeping parts organized, following the manuals, and checking for worn components.

Testing and Fine-Tuning After Rebuilding

Methods for testing the functionality of the rebuilt lathe. Adjustments for precision and performance improvements.After rebuilding your lathe, it’s time to test it. Begin by running the lathe at different speeds. Listen for any strange noises. A smooth sound means it’s working well. Measure the parts your lathe makes. If they aren’t perfect, adjustments may be needed. You can tweak the machine in these ways:

- Check and tighten all bolts.

- Align the tailstock and spindle.

- Adjust the tool rest for better fit.

Each change helps improve accuracy. This way, your lathe will work like new!

What are methods for testing a rebuilt lathe?

You can run it at various speeds and listen for sounds. Also, measure the pieces it makes. Look for any mistakes or rough spots.

Maintenance Tips for Longevity

Routine checks and maintenance practices. Best practices for preserving lathe performance over time.Keeping your lathe in tip-top shape is not just smart; it’s fun! Regular checks are like giving your metal lathe a check-up. Look for any loose bolts or worn parts. Lubricate moving parts often to avoid squeaks and squawks. It’s soothing, trust me! Cleaning the lathe regularly helps prevent grime build-up, which is its version of a bad hair day. Remember, a happy lathe makes happy projects!

| Maintenance Task | Frequency |

|---|---|

| Inspect bolts and parts | Weekly |

| Lubricate moving parts | Every month |

| Clean the lathe | After every project |

Conclusion

In conclusion, rebuilding a metal lathe bench can improve your workspace and enhance your projects. You’ll enjoy better stability and accuracy when working with metal. Start by evaluating your current setup. Research the best materials and tools online, and consider asking for help from experienced builders. Let’s get started on your lathe rebuilding journey!FAQs

What Are The Essential Steps Involved In The Rebuilding Process Of A Metal Lathe?To rebuild a metal lathe, you start by taking it apart. Clean all the pieces to remove dirt and old oil. Next, fix or replace any broken parts. Then, put everything back together carefully. Finally, test the lathe to make sure it works well.

Which Materials And Tools Are Commonly Required For Rebuilding A Lathe Bench To Ensure Stability And Accuracy?To rebuild a lathe bench, you need strong materials like wood or metal for the base. You’ll also need screws and glue to hold it together. Use a level to check if it’s straight. A tape measure helps you get the right sizes. Lastly, a saw or drill will help you cut and make holes.

How Can One Determine Whether A Metal Lathe Is Worth Rebuilding Or If It’S More Cost-Effective To Purchase A New One?To decide if you should fix a metal lathe or buy a new one, check its condition first. Look for worn parts and rust. Then, estimate the repair costs and compare them to the price of a new lathe. If fixing it costs less than buying new, consider rebuilding it. If not, it might be better to get a new one.

What Are Some Common Issues That Can Arise During The Rebuilding Of A Metal Lathe And How Can They Be Addressed?When rebuilding a metal lathe, you might face a few problems. First, parts can be hard to find. You can check online or ask at tool stores for help. Second, some pieces might not fit well together. Make sure to measure everything carefully before you start. Finally, it can be tough to adjust the machine once it’s put together. You can practice with smaller projects to get better.

How Can The Design Of A Lathe Bench Affect The Overall Performance And Precision Of A Rebuilt Metal Lathe?The design of a lathe bench can make a big difference in how well your metal lathe works. A strong, stable bench keeps the lathe from shaking. This helps it cut metal more accurately. If the bench is too low or too high, it can be uncomfortable for you to use. A good design helps you work better and make better parts!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Essential Steps Involved In The Rebuilding Process Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To rebuild a metal lathe, you start by taking it apart. Clean all the pieces to remove dirt and old oil. Next, fix or replace any broken parts. Then, put everything back together carefully. Finally, test the lathe to make sure it works well.”}},{“@type”: “Question”,”name”: “Which Materials And Tools Are Commonly Required For Rebuilding A Lathe Bench To Ensure Stability And Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To rebuild a lathe bench, you need strong materials like wood or metal for the base. You’ll also need screws and glue to hold it together. Use a level to check if it’s straight. A tape measure helps you get the right sizes. Lastly, a saw or drill will help you cut and make holes.”}},{“@type”: “Question”,”name”: “How Can One Determine Whether A Metal Lathe Is Worth Rebuilding Or If It’S More Cost-Effective To Purchase A New One? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To decide if you should fix a metal lathe or buy a new one, check its condition first. Look for worn parts and rust. Then, estimate the repair costs and compare them to the price of a new lathe. If fixing it costs less than buying new, consider rebuilding it. If not, it might be better to get a new one.”}},{“@type”: “Question”,”name”: “What Are Some Common Issues That Can Arise During The Rebuilding Of A Metal Lathe And How Can They Be Addressed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When rebuilding a metal lathe, you might face a few problems. First, parts can be hard to find. You can check online or ask at tool stores for help. Second, some pieces might not fit well together. Make sure to measure everything carefully before you start. Finally, it can be tough to adjust the machine once it’s put together. You can practice with smaller projects to get better.”}},{“@type”: “Question”,”name”: “How Can The Design Of A Lathe Bench Affect The Overall Performance And Precision Of A Rebuilt Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The design of a lathe bench can make a big difference in how well your metal lathe works. A strong, stable bench keeps the lathe from shaking. This helps it cut metal more accurately. If the bench is too low or too high, it can be uncomfortable for you to use. A good design helps you work better and make better parts!”}}]}